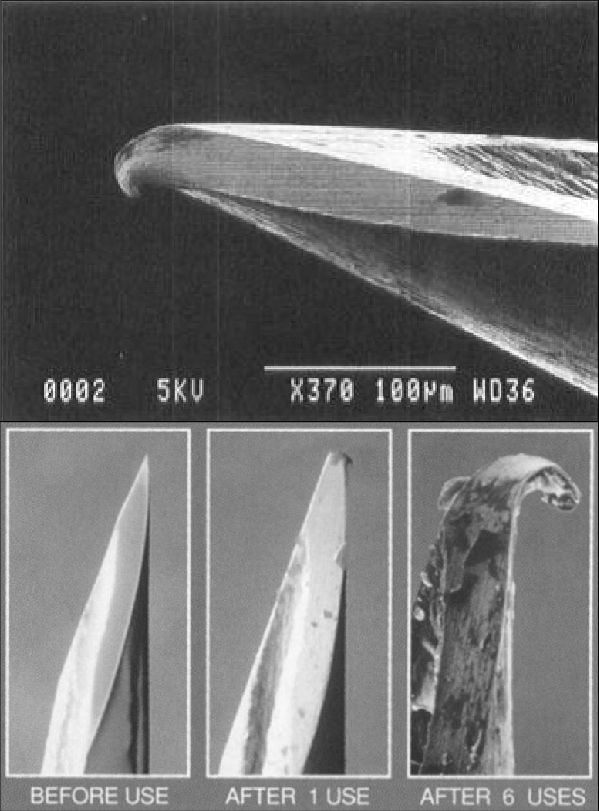

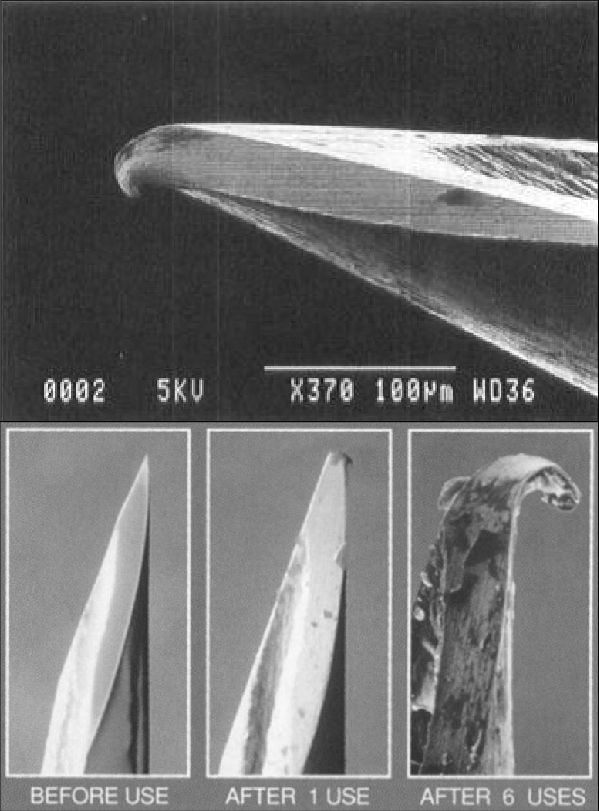

See that little hook at the point? This is from penetrating skin ONCE.

This is why you don't re-use needles folks!

Rules:

1.. Please mark original photos with [OC] in the title if you're the photographer

2..Pictures containing a politician from any country or planet are prohibited, this is a community voted on rule.

3.. Image must be a photograph, no AI or digital art.

4.. No NSFW/Cosplay/Spam/Trolling images.

5.. Be civil. No racism or bigotry.

Photo of the Week Rule(s):

1.. On Fridays, the most upvoted original, marked [OC], photo posted between Friday and Thursday will be the next week's banner and featured photo.

2.. The weekly photos will be saved for an end of the year run off.

Instance-wide rules always apply. https://mastodon.world/about

See that little hook at the point? This is from penetrating skin ONCE.

This is why you don't re-use needles folks!

I can't believe it's that fine or how easily human skin can bend it. I guess our skin is a better protector than I'd given credit.

All these images are super interesting and I'm truly glad they got posted.

Holy shit. I noticed that too and thought that must be one of the ones that hurts going in, figured it was from when they draw the medicine into the syringe, or maybe even from taking the cap off.

There are other reasons.

In that last one, you'd probably be able to see the bent over tip with the naked eye. You'd certainly be able to feel it if you ran your finger over it. It would take some force and would be pretty painful to use.

Its crazy how crude all of our tools look at this magnification.

Some medical tools look crude even at regular size… they don’t call orthopedics bone carpenters for nothing!

People would never set foot in a hospital again if they found out how many orthopedic surgeries involve a dewalt drill at some point.

My knee replacement was carried out with an epidural pain block, plus sedation. I came down from cloud nine briefly to wonder why someone was doing renovations while surgery was in progress - then realised all the drilling and hammering was my new joint going in. Phew! Back to lala land...

Lmao "oh shit I'm a house"

I'm just going to leave this discovery here.

That's great. I rotated through an ortho lab in the 1990s, and the joint replacement kits back then included a sterile, disposable drill that you were just supposed to throw out after the procedure.

I recently saw a knee replacement that used one of those ryobi oscillating cutters (the ones that were super trendy a few years back). Total garbage for home use, but man with a 3D printed cutting guide shaped to fit over the bone, they finished the osteo and arthroplasty portions in ten minutes flat. Just insane what we can accomplish when we combine modern volumetric imaging techniques with coupons for home depot.

I've seen enough joint replacement videos, especially knees, to think carpentry skills are a job requirement.

I've started calling folks taking X-rays the bone paparazzi.

I guess that's better than calling neurosurgeons spaghetti artists

I gained an appreciation for how precise/sharp our tools are when I learned microtomy. If you so much as touch the cutting edge with anything outside of its intended use it messes up that area of the blade instantly. Same goes for a nice pair of chef's knives.

It actually looks a LOT smoother and sharper than I expected. Look at microscope photos of razors and knives and they look like chewed up chisels.

I believe it’s damaged by piercing the skin, it’s pristine before.

for this magnification it is actually pretty smooth

source: I have used an SEM at my university and never saw something this smooth even at higher magnifications

of course I didn't look at medical tools but this shows that they are crafted very precisely

Yet it emphasizes just how precisely tiny the tip of the needle is.

Crude aspects of fleshy meatbags.

From the moment I understood the weakness of my flesh, it disgusted me. I crave the certainty of steel.

certainty of steel.

Yeah.. take a few material courses in engineering...

It's not so certain a lot of the time...

I crave the certainty of neutronium

The quality of steel has generally gone down in the last hundred years. I'm not trying to dunk on China specifically because cheap steel is manufactured in more places than just there - but I recently saw a stress test of a cheap modern maul made from Chinese steel vs a 100 year old American maul and it's like they aren't even in the same category. The old ones were indestructible.

The purity of the blessed machine

Glory to the Omnissiah

username is Gork

haha yes I am very human too and i too hate it when my skin gets damaged and needs to be replaced because it invokes a feeling called pain and it is a very unpleasant feeling

This is fascinating. I mean we all know the theory, but to actually see the cells under magnification puts you in range, and makes you wonder what else there is to know. And the answer is always MORE.

Education should work more practical application in with the theory. I'm looking at you, calculus!

I mean, calculus is a thorny issue in that it is mostly necessary for engineering, but is not usef for humanities. Not teach it, and STEM people will have jump of levels going college. Teach it, and humanities people will inevitably complain.

Personally, I think it is good to teach calculus just for the technical communication aspect.

Seriously. I'm in my 40s and this is the first time I've ever had any sense of scale for red blood cells. Very cool!

how were the colours added? like do you carefully select each isolated cell to add the colour or is there some kind of algorithm?

When I segmented 3D MRI and CT scan images before I used the contrast borders for help a lot. There were some algorithms for finding edges that you could tune by setting search radiuses and thresholds. There was also an option of growing an area by a certain amount of pixels outward, and then threshholding the result back down to only the brighter parts, that kind of thing. You had to be a little clever about how you'd combine it. And ultimately, sometimes I just had to add and subtract a few points manually.

Segmenting is more assigning areas to distinct objects (separating bones from the rest in my case), but you could totally use it as a basis for coloring, so I assume the process is similar here.

These are manufactured differently from most of the stuff you'd be looking at.

Rather than milling and grinding, the needles are made from a sheet of stainless that's rolled and welded, then drawn down to whatever size it needs to be, basically stretching the material out. Kinda like when you make a snake with silly puddy and pull it apart.

Then the points are ground in. Gives you a ridiculously smooth finish.

Interesting info, thanks!

But I think you may have accidentally typed in the wrong thread? I was talking about the image manipulation, not the manufacturing :-)

Sure did. Whoops!

Extrusion?

Extrusion is a little different but similar. It would be easy to confuse the two.

Extrusion is forcing material through a die to get a shape. There's a play dough toy that is effectively a play dough extruder. You put the dough in the hopper, press a lever, and you get a star or whatever.

The surface finish you get kinda depends on the material, it will feel very smooth but won't be nearly as smooth under a microscope as this. If you're in to 3D printers, the aluminum arms are generally made of 80/20 T slot, which is an extruded material. Also like, all dry pasta is made this way.

Drawing is stretching the material. You're pulling it through the die rather than pushing it, and getting a shape, and the act of stretching it out makes it incredibly smooth and can yield a stronger product.

This is also how record stylus needles are made. And frequently brass tubes. It's not done through dies, but Chinese noodles are made in a similar process, constantly stretching until they're the desired size.

Mmmmm red caviar ... 😋

Thank you for the caption. My fist thought was “how did they take this photo in color?!?”

I actually thought optical microscopy worked just fine at this scale.

I know it's not the case for this photo, but if a 7 μm red bloodcell is reflecting red light (700nm, aka 0.7μm) under a bright white light, wouldn't the smallest discernable detail of the red blood cells be about a 10th of its width? Is that not roughly the detail we have in this image?

I'm making an assumption that the distance between discernable parts roughly parallels the wavelength's width. I could be wrong tho

I wonder what gauge needle that is?

At very rough estimate, I would guess a 30 gauge needle. They have an outer diameter of .31 mm. A blood cell is about 7 micrometer across. It looks like you can fit more a smidge fewer than 50 cells across the thickest part of this needle. Cheers!

I want to eat a red blood cell. Like one the size of my hand that tastes like a gummy bear

Can't you just eat some real gummy bears? I think they even make big ones.

Frighteningly big.

Please do not buy your child a gummy bear bigger than their head. We have enough problems with diabetes as it is.

Would probably taste like a rusty nail, but gummy.