Right now looking into bang for the buck workhorses with a small footprint/build volume. A description that fit the Prusa mini+ perfectly in the past, but it feels like Prusa is a dinosaur that hasn’t moved with the times.

So who is still buying the Prusa mini+ and why?

Personally: While Prusa has outstanding support, good data protection, and does good things but there is now the Bambu Lab A1 mini.

Prusa mini is at the moment 500€ plus 20€ for a filament sensor (sic., it’s nearly 2024 and that’s an paid upgrade on half a grand printer) and another 7€ for WiFi.

Bambu Lab on the other hand is 320€.

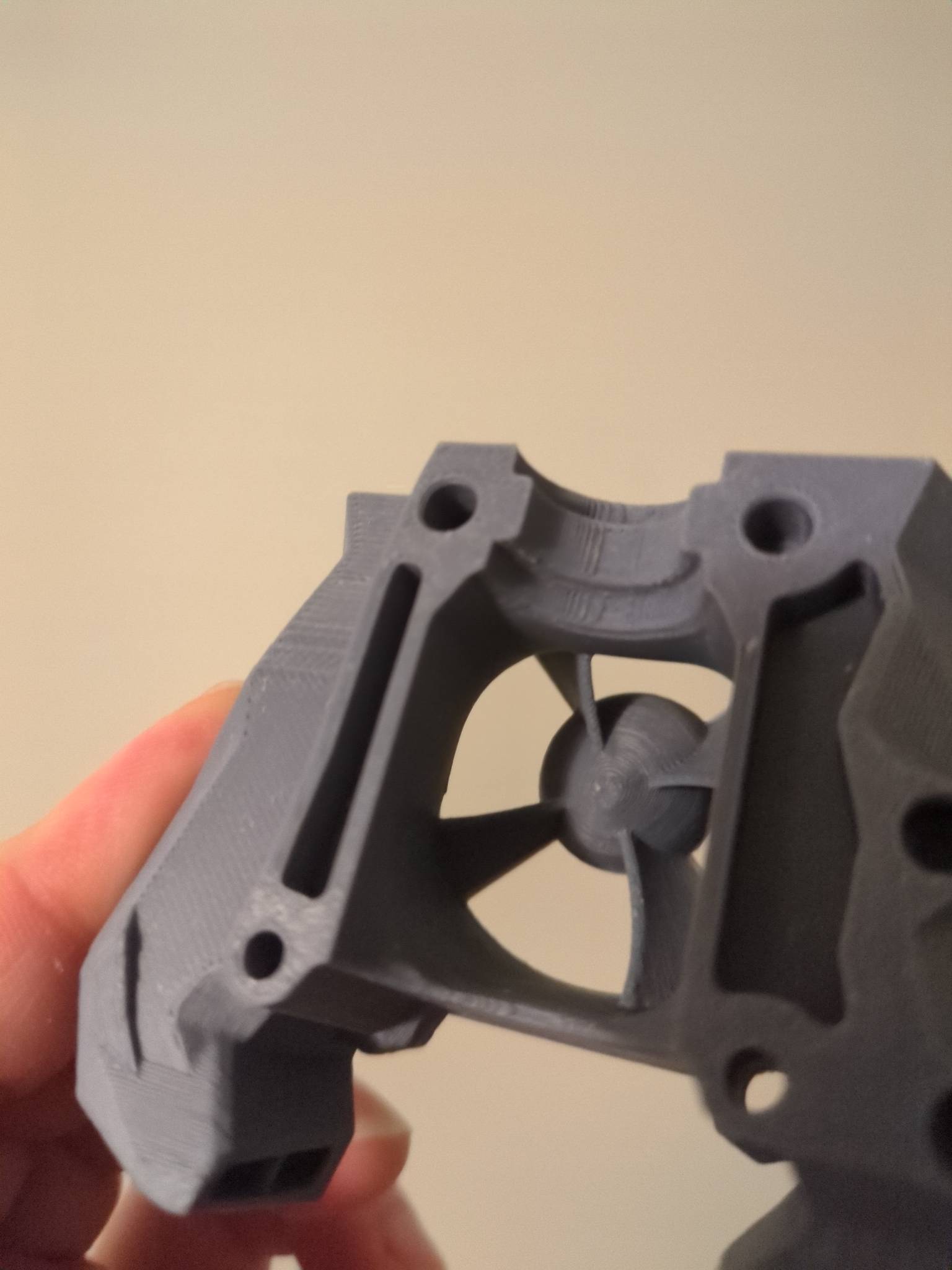

Looking at the specifications, the A1 looks like a clear winner: For maintenance, there are three tasks: 1. cleaning and lubricating the mechanics (both are the same in this respect); 2. cleaning the build surface (both are the same); 3. maintaining the hotend and here Bambu Lab is clearly the better system as you can replace the nozzle in just a few seconds compared to Prusa’s E3D v6 hotend, which requires hot tightening.

The operation is not that different. Both support network, web interface, and automatic bed leveling probed at the nozzle. Bambu Lab has a camera built in, but this requires the printer to be connected to the BambuLab cloud, which may not be possible as the model data is shared with/uploaded to China. I would say this is still a strong point for Prusa as privacy is not an issue with their printers which means they can be easily deployed.

Performance should be close with input shaping enabled, but the A1 mini has the higher flow rate hotend, which means BambuLab is once again the winner (still no highflow at only 28 mm^3/s but twice the flow of a Prusa V6).

The build volume is identical and the footprint is also almost identical, so again no point where Prusa beats BambuLab.

Value? I have already mentioned it. 1.6 Bambulab for the price of 1 Prusa is a clear answer. If Prusa still had the 400€ original launch price and a filament runout sensor included, maybe the answer would be Prusa due to privacy/easier integration. The 200€/printer price difference is so significant that I don’t see who is still buying multiple Prusa mini+.

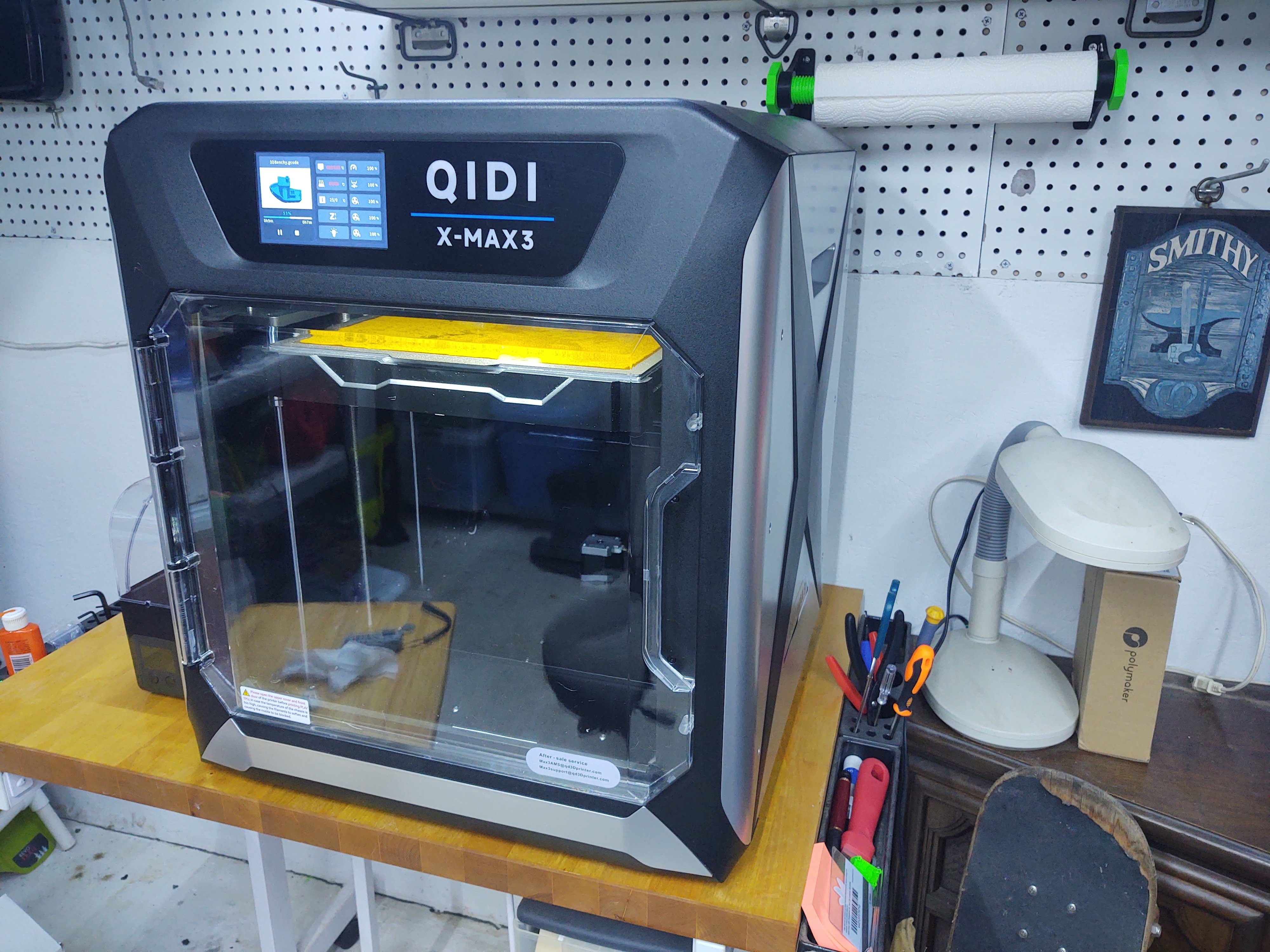

Btw. is there another printer on the market that just works paired with a small footprint and excellent value?