Lemmy Shitpost

Welcome to Lemmy Shitpost. Here you can shitpost to your hearts content.

Anything and everything goes. Memes, Jokes, Vents and Banter. Though we still have to comply with lemmy.world instance rules. So behave!

Rules:

1. Be Respectful

Refrain from using harmful language pertaining to a protected characteristic: e.g. race, gender, sexuality, disability or religion.

Refrain from being argumentative when responding or commenting to posts/replies. Personal attacks are not welcome here.

...

2. No Illegal Content

Content that violates the law. Any post/comment found to be in breach of common law will be removed and given to the authorities if required.

That means:

-No promoting violence/threats against any individuals

-No CSA content or Revenge Porn

-No sharing private/personal information (Doxxing)

...

3. No Spam

Posting the same post, no matter the intent is against the rules.

-If you have posted content, please refrain from re-posting said content within this community.

-Do not spam posts with intent to harass, annoy, bully, advertise, scam or harm this community.

-No posting Scams/Advertisements/Phishing Links/IP Grabbers

-No Bots, Bots will be banned from the community.

...

4. No Porn/Explicit

Content

-Do not post explicit content. Lemmy.World is not the instance for NSFW content.

-Do not post Gore or Shock Content.

...

5. No Enciting Harassment,

Brigading, Doxxing or Witch Hunts

-Do not Brigade other Communities

-No calls to action against other communities/users within Lemmy or outside of Lemmy.

-No Witch Hunts against users/communities.

-No content that harasses members within or outside of the community.

...

6. NSFW should be behind NSFW tags.

-Content that is NSFW should be behind NSFW tags.

-Content that might be distressing should be kept behind NSFW tags.

...

If you see content that is a breach of the rules, please flag and report the comment and a moderator will take action where they can.

Also check out:

Partnered Communities:

1.Memes

10.LinuxMemes (Linux themed memes)

Reach out to

All communities included on the sidebar are to be made in compliance with the instance rules. Striker

view the rest of the comments

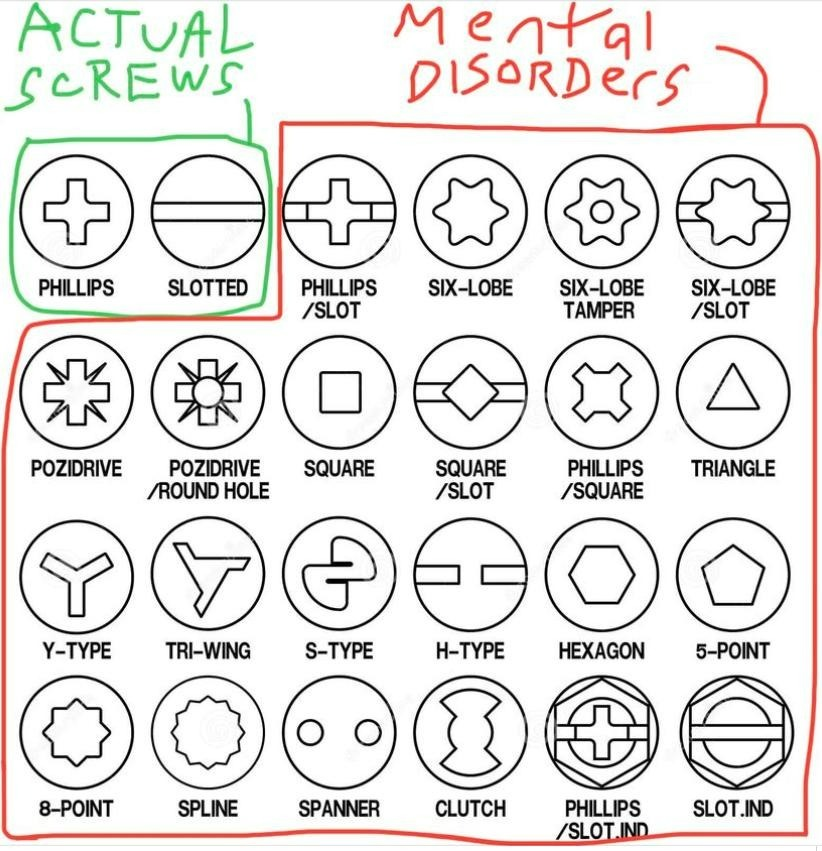

Philips screws are awful. They strip if you look at them wrong. Flatheads should only be used on thumbscrews just in case you need a little extra torque from a screwdriver.

Torx and Hex are excellent.

I work on electronics and woodworking and Phillips are the utter worst of both of them. The thread lock in computers makes them easy to strip when unscrewing. The resistance of driving them into wood makes them guaranteed to strip when screwing. Fuck them.

The big issue I see with people driving Phillips screws is that they don't use a large enough driver size. Computer screws for example are Phillips #2 and I've never had an issue with them stripping.

I use the correct driver, I'll go through my kit to find the best fitting bit. It simply comes down to the fact they are designed to strip to avoid "catastrophic failure". Plus the fact that companies use intentionally cheap, soft screws, to make repair and service harder. Cough cough zinc screws on a $10,000 iMac (steel screws would have cost 25 cents for 10, zinc like 5 cents for 10, fucking ridiculous).

I read that the thing about them being designed to strip to prevent worse failure is just a myth. Or at least they weren't originally designed to. It said that the original patent never contained any feature for that. Wouldn't surprise me though if modern companies do use screws designed to strip to prevent disassembly/repair.

I think originally the screws would cause the driver to cam out and stop driving if a certain amount of force is applied but the screws are so soft and cheap that the harder driver damages the screw head when it cams out.

This and the centered shape that Philips and Robertson have were key. The lack of a sharp driver bit being able to slip out of the fastener prevented a lot of injuries.

However, Philips, at least, needs to go away.

I always figured it was intentional but for the other reason: screws soft enough that overtightening can't damage/crack the multi-thousand dollar components, the screw head cores out first.

That's great, but then you can't get your multi-thousand dollar component unscrewed anyway so what was the point?

It's also a design flaw that it's so easy to use the wrong sized driver and it will sorta work. It might be annoying that you have to have a set of different star drive or hex drive bits, but you're less likely to strip them.

Could be that it's not a Philips but a JIS. I didn't even know that JIS existed until a couple years ago. The shape is close enough to Philips to mostly work but make it super easy to strip.

Maybe I'm just being lucky but I've never experienced screws stripping anymore since I've started getting better tools for myself.

And in woodworking it can also help to pre-drill a hole using your smallest drill, before screwing a screw in. This also prevents the wood from cracking. I've also seen wood screws that have some lubrication pre-applied.

The problem is, when working with electronics, you can have a great screwdriver but it won't help if the screws in the device are very cheap (and probably partially stripped already from someone opening it previously).

I swear I've had stuff with stripped screws right from the store.

I'll be honest that I've never really experienced problems like that before. I've had cheap screws and partially stripped screws. But so far I've always been able to open them with the right screwdriver.

But I believe you when you say you did and maybe you have a lot more experience than I do so I'll respect your opinion.

I haven't had any completely fail yet, but I've seen some come worryingly close. I don't really have all that much experience, but from what I've seen it just doesn't seem like the most reliable design.

PC fan screws come to mind because they are self tapping and a lot of people seem to not use the right screwdriver or don't yet know the trick of running the screws in and out of the fan one time outside of the case first.

Torx gang unite.

We had our 20 y/o deck repaired and stained last year. I was chatting with the overseer about what he was going to do and the topic of screws came up; he said he was going to use Torx, and only ever used Torx anymore - I just about cheered.

I'd been losing hope in humanity lately, but little signs of sanity like this, professionals finally getting rid of the hell-bits that are Phillips heads, lifts my heart and gives me hope.

These days, all but the cheapest outdoor-grade screws in the US are torx, generally with a bit thrown into the box that, while cheap, should work fine for a few boxes' worth.

Freaking awesome. Better and better. We've finally fixed the screw heads, and pretty much also computer connectors (and small device chargers!) with USB-C. Just in time for the end of the world via total ecological collapse.

Great times.

I work at a big box hardware store, and I can confirm that almost all deck and structural screws are moving to torx. (much to the older generations dismay)

That's what a worker at my local Ace store said: they were slowly transitioning to Torx.

I've heard that was more of a European thing, but the only two serious contenders are Pozidriv vs Torx for screws (and hex vs Allen for bolts).

I just checked my local hardware store's website, and out of the 176 kinds of 4/4.5mm screw boxes in their inventory, 74 are Torx, 55 are Pozidriv, and 38 are Phillips (ew).

Either Torx or Pozidriv is fine when used properly, however most DIYers don't understand the difference between PZ and PH and end up stripping their heads. Also it's much harder to use the wrong-sized bit with Torx than PZ.

So yeah, Torx wins in just about every category and other heads only get manufactured to appease old people and penny-pinchers.

That's one of my issues with Pozi - it can be hard to see the markings, and not everyone has great eyesight. I mostly object to Phillips-related screws because there are so many variations that mostly look the same and require a table to differentiate. And none have the torque-transfer performance of Torx. Plus, you can use a hex head in a Torx bit in an emergency and you don't much care about either the bit or the head.

I'm not sure I've ever seen a philips or slotted deck screw. I have and have purchased many boxes of these things and they've always been nearly 100% Robertson. Is this a US thing?

Yes, and you're Canadian. Robertson is the standard there, and while it's used in other countries, not nearly as much.

In the beginning was slotted heads, mainly because mass machining and casting wasn't good enough to have more precise forms. Then came the Great Connector Wars, and in the US the Phillips head won and was standardized; almost every house built in the US in the past 80 years will be built with these (and nails). Slotted heads are much less common, but you find them in various specific places, like where the heads are visible and you want to hide the screw as much as economically possible.

Canada, however, was smarter and standardized on the Robertson head; IIRC one reason for the divergence was the Phillips licensing cost. In any case, Robertson is superior to Phillips in most ways, except it's even worse to dig out if it gets painted over.

As machining improved, many attempts were made to improve on Phillips, which mostly amounted to polishing a turd; Robertson remained unchanged as it was already pretty good.

Then came hex, which is great except it's structurally pretty terrible for the head. Still, it can be seen as an improvement in Robertson, but not quite so good as to be worth all the retooling. Good enough that it's probably the second, or at least third, most popular head in the US.

Finally, someone did some fucking math and came up with Torx, which is provably and demonstrably superior to all other screw heads. It maximizes force transfer, and leaves more material in the head; it's harder to strip out, and can be applied effectively to very small screw heads. There's a security version, which was mostly useless (for intended purpose) the day after it was released, but beyond that, there's no real improvement that can be made.

The Phillips patents expired decades ago, so it's holding on mainly from inertia. Commercial contractors don't have much invested in it, because they have to literally buy boxes of replacement Phillips heads because of how shitty the design is and how often the heads break. While manufacturers have a steady stream of revenue from selling replacement Phillips tools that have broken, this is balanced by the mouth-watering prospect of every contractor in the US buying new Torx size-sets and high-end Torx tools. And the screw makers probably DGAF as they'll sell screws either way; Torx screws might be a little more expensive - they used to be, but I haven't compared lately.

Canada may just motor on using Robertson; there's less incentive for them to retool since Robertson isn't nearly as crappy as Phillips, so the cost/benefit to upgrade to Torx is less compelling. But who knows?

The image feels like it should be posted in c/unpopularopinions

The only other legitimate use I've seen for flatheads is on wooden boats, where you'll be gooping the head up with tar for waterproofing. Since you'll eventually have to scrape it back off again to get to the fastener, you want a simple geometry that's easy to clean.

Square (Robertson) drives are actually great too. Better than Hex/Allen, but Torx is the most reliable, and the most German. Phillips can take a long walk off a short pier.

I do wish Robertson heads were more common. They're almost as tough as torx, but tapered to stick on the tip of the tool, which is so convenient.

The ones with bumps in the middle can go fuck themselves

Square is nice too but square/Phillips is a good damn lie. Because the Philips side of it doesn't work well enough so it is still just a square but with extra slots

I feel like spanner would be the best for not having shit getting stripped. But that's just looking at this diagram; never seen them IRL.

They're mostly just used for tamper-proof screws for things like bathroom stalls so people can't take them apart as a "prank" or whatever. The screw driver bits tend to break easily, which is usually worse than the screw stripping.

Hexagons are the bestagons