TL;DR: I tried lots of CAD stuff with an eye towards someday being able to commercialize designs. F360 would be great if I could trust Autodesk. Solid Edge, Solidworks, and Onshape all have issues too. I want to make myself like FreeCAD. Some other options like Alibre are interesting, and many get weeeeird.

I don't make particularly sophisticated designs, but I'm eager to learn, and I have delusions that I might one day stumble across a design that once fabricated could end up making me a few bucks (Narrator: he was mistaken). I'm certainly not there yet, but my other hobby is being a cheap-ass and a contrarian, so for the last few weeks I've been hunting for every weird free CAD program I can find, plus one weird but heavily discounted one, plus several free trials. Lately, I've been making my go-to quickie design to test basic part functionality in a lot of different programs, which I will discuss, but as a mostly-former lawyer, I've also been thinking about license terms and paths to small-scale commercialization. Haven't actually pulled the trigger yet on paying for anything, with one exception because it barely counts. Notably missing will be Code-to-CAD options like OpenSCAD. I have a couple of them, and I have dabbled in PHP, Python, Pascal, and BASIC over the decades, but my brain just doesn't "see" in code.

The sample part is generally along these lines: a rectangle, ellipse, and circle, trimmed to be one sketch, one corner with a 2D fillet, then extruded. After, I put a fillet on the top surface and a chamfer on the bottom. Then I punch a hole through the side and fillet and/or chamfer the openings. This does a helpful number of basic things in very little time. If 2d is constraint based, it shows me how those work. I also see how you set up a working plane on a face and how aggressive the filleting can be, particularly where the ellipsoids meet the rectangle at a rather sharp angle. Basically, it tells me, "Can this program be used at all for basic design for 3D printing?" All very newbie and idiosyncratic, but maybe it will help someone and spur discussion.

So, without further ado, here are some thoughts:

- Big time (by hobbyist standards):

Fusion 360: Parametric. Loads slow, but it works. The part designs fine. Ten part limit could easily become annoying if I start doing assemblies, but for the moment it's a rather fair compromise, since a simple toggle reactivates a file. Filleting is really robust for the curves; it tries to accommodate crazy design choices. I kind of hate how much I like it, because I hate the feature erosion, and the price creep to avoid that, that Autodesk has been doing. Still, as subscriptions go it's not terrible at the $400-$600/year mark. That raises another point, which is that it would be one of the easiest to navigate a hobby to side-hustle ("H2SH") transition, since the price is not insane and the $1000 revenue limit on the free tier is chintzy but exists. It also works almost perfectly with the serial port(!) Spaceball I bought off ebay, with only button customization no longer working.

Solid Edge Community Edition: Parametric. The interface does some unintuitive things compared to F360, but after a bit of wrestling, it started to click, and there's a search box for tools; that's actually super thoughtful. Ultimately, the part designed fine, and Siemens' strategy to nerf is a little different than Autodesk's. Instead of removing features, they simply refuse to let you open CE version files in the commercial version, and I believe the opposite way permanently converts that copy of the big-boy file. The other issue here is the licensing. There is no ramp-up like with F360. You make money, you need commercial. That said, the subscription is pricy at ~$1000us per year but not insane.

Solidworks Maker Edition: Parametric. I HAVE NOT TRIED IT YET. I assume it can do everything I would want and more. The Maker edition is not terribly priced, and I believe the Titans of CNC deal gets it down to around $50 a year versus the $100 regular price. The old EAA discount is not as good these days, I understand. There are a few things holding me back. First, gotta pay up front, as I understand the fully online version is kind of crap, but as far as I can tell that's what the free trial gets you. Second, I gather the 3dExperience Licensing portal leverages a robust but non-intuitive commercial PDM system, so even logging in and launching the desktop version is challenging with the current products, and people seem to universally despise it. Third, it seems like Dassault has no clear strategy for this market segment and the version could go away, which is a problem because, fourth, there is a huge donut hole in the licensing scheme. Maker edition is super cheap, and actually has a fairly generous H2SH cushion of $2000 profit. I am not sure I'd ever get past that even if I did accidentally make something a few people thought was cool, but if one were to manage it, there is nowhere to go except apply for the startup program, which requires legal formalities. The next step up is just the full, multi-thousand/year commercial license. That tends to leave it less desirable than SE or F360, for this particular scenario.

OnShape: Parametric and online. I want to like it. The part designed pretty well actually, though it gave up on compound fillets much quicker than F360 or SE, but it's certainly usable. The online only part is potentially annoying, but I'm not doing CAD at a cabin in the mountains (some do... much respect), but it's also an advantage, as this leaves OnShape working perfectly in Linux in this notoriously Windows-centric category of software. The way they have the full screen browser window actually looks a lot like a "real" app. I found it at least as responsive as F360. The bigger issue here is, again, pricing and licensing. Free is great; I don't love that the designs are public, but whatever; I'm much more likely to use CAD to make a thing worth selling than a file worth selling. The licensing problem is that while I am barred from commercially using my files, by the terms of use, NO ONE ELSE IS. They specifically grant users the right to do anything they want with other people's files, including sell them. It's kinda bullshit, actually, and I've had a polite but unproductive exchange with their legal department about it. Pricing-wise, it's not quite Solidworks, but there's a donut hole in their market segmentation; for a less mature product than SE, you have to jump straight from free to $1500/year.

NX and Illustrator and Creo Parametric. Didn't try them. Few/any license discounts, and it's clear that the corporate parents view other offerings as filling this niche.

FreeCAD: Parametric and open source. First off, I'm better with it than I was even a few weeks ago, and to a certain extent, it should simply BE the answer. It's free for any use and it's a proper parametric modeler. It works as well on my Kubuntu laptop as it does on my Windows desktop. As my understanding has increased, I'm more aware of why it does certain things, and what an impressive piece of software it is to work at all comparably to some of the commercial packages. I haven't personally hit a wall with topological naming or had any significant crashes, but I'm still kind of playing and not working and reworking any projects. The sample part designed reasonably easily, but similar to OnShape it's more hesitant about balls-to-the-wall fillets, giving up as soon as any two edges' fillets touch (edit: anywhere except the expected vertex, that is). FreeCAD is more persnickety about sketches and constraints, though less than I used to think. Overall there is still a general sense of "We've only just barely got this thing holding together, so don't get cute." It "enforces good design" by not working well if you don't learn its definition of good design. There are also still a lot of QoL issues with the GUI and no real attempt to bring in influences and widgets from direct modeling. FreeCAD is pure of heart and pure of thought, but I'm not sure I'm quite there, though I can at least imagine it now, and I will never not have it installed. One additional plus, a simple Serial-USB adapter is enough to get the eBay Spaceball working on linux.

Alibre Design: Parametric. I've just about wrapped up my free trial, and while it's got its own quirks, I like it. I mostly used Atom, the lowest tier, and while the interface looks a little dated, it's a sort of "Clean" dated, and it's fine. The sketching and extruding works fine. Like FreeCAD, it divides additive from subtractive operations, but again, that's not a deal breaker. Subscription prices are pretty reasonable, which is good, because while Atom3D is nice and extremely cheap at $150 permanent with no updates ($200 with one year's worth) or $100/year, it lacks all Boolean operations. You absolutely have to figure out a way to get your sketch extruded or revolved to get the shape you want. Maybe I've played with direct modelers too long, but my goodness that's a beatdown. Luckily, the next step up is still fairly reasonable at $700 permanent ($350 for 1yr updates) or $300 yearly subscription, and it includes booleans, some direct modeling, and quite a few other features. This one is kind of a contender, but the question is always, "how much better is it than FreeCAD?" Also, there is no free plan. Trial, then pay or delete.

Shapr3D: Direct for now, Parametric in beta. I only played around in the non-beta for a bit, as I already have a direct modeler. The parametric constraints are a little hit and miss, and there are still odd little incompletions in an otherwise polished app. For instance, 2D fillets must be done manually with arc and trim. Still, the UI has evolved nicely out of its iPad origins and the organization on screen is pretty nice. The iOS heritage also shows with the pricing, where the free tier is completely hobbled by not even exporting usable STLs, but the subscription is pretty modestly priced at $300/year. One to watch for desktop, and probably already a good option if you work on iOS or prefer direct modeling.

Plasticity: Direct (and proud!), has Linux version. I let my free trial expire without robustly testing it, but it was sort of exactly what is claims to be. A direct modeler that works a lot like Blender and is more than happy to fillet the hell out of anything. I understand a parametric history tree and constraints-based drafting are not really part of the roadmap, so that direct modeling concept would need to be what you're after. It's also a one-man show, so burnout or taking a "real job" is a distinct possibility, but the price is good at $150 for a permanent license with a year of updates.

(EDIT) Rhino: I didn't try, but probably should have. A bit more expensive than Alibre or BricsCAD, but permanent licenses that don't price out small business are available.

TinkerCAD: Direct and different, online. You CAN do more with it than people like to imply, but the paradigm of groups and solids and holes is way weird compared to mainstream CAD software. Still, it's really intuitive to those coming from some other background. Woodworking for instance. It's basically, "Here is a thing. I can glue it to other things. I can also make holes in things." The alignment and cloning options remind me a little bit of apps like Inkscape, and that's not necessarily a bad thing either, but it's not quite scalable. Also no built-in fillets and chamfers, and that's really what pushed my out of its loving embrace.

SolveSpace: Parametric and open-source. Imagine if Freecad were distilled down to its part design workbench, and equipped with literally the bare minimum of tools to make an arbitrary solid, its own utterly unique (AFAIK) paradigm on how to interface with things, and with barebones presentation, yet somehow the whole was more than the sum of its parts. Following along with a SolveSpace tutorial is actually kind of fun. If they figure out a way to shoehorn fillets and chamfers in, it could be a real factor in the hobbyist space. Using construction geometry and booleans to soften every single edge is not my idea of productivity, however (see also TinkerCAD).

Designspark Mechanical: Direct Modeling. Aww, man, I wanted so much to like this one, and I guess in some ways I still do, but it can be frustrating. It's a downscaled version of Ansys Spaceclaim, probably the best known professional app that's specifically for Direct Modeling. The free tier is licensed for commercial use, which is extremely rare. The only thing is, they have absolutely nerfed it as far as interoperability. You can import absolutely nothing CAD-native that isn't from Designspark, and while you can export printable STLs, that's about it. You also can't mirror features, which depnding on workflow might double your work. Now, on the flip side, the next tier up is a very reasonable $145/year, and it opens up the import/export and mirror functions. The other thing is that being designed as a direct modeler, most of the traditional functions are bundled up into the push/pull tool, and it can feel a bit claustrophobic; you also have to remember to space/tab into your measurement, or it will just assume you want to wing it. Parametric modeling is not quite the end-all be-all for the lone wolf designer doing one-offs that it would be for a production shop, but I'm not even sure DSM is top tier at that. For decent commercial software, though, it's quite cheap, and poking around the forums, it seems like you'd be fine to buy a single month of subscription to mess with your parts, since whatever it allowed you to do in the free tier is already fine to use commercially. Finally, there's a new feature for constraint-based 2D sketching, but those sketches are still consumed (i.e. they are integrated in as the edges of the extrusion and can no longer be edited once in 3D). This is a half measure, but with some forethought and careful saving/version control, it could get you halfway to a parametric modeler.

BricsCAD: Parametric. Okay, I admit it, I had an initial impression that Alibre was easier to use than this fork of an old AutoCAD (though I understand it's the nicest of such forks, and better than the various IntelliCAD packages), so I let the free trial sit there until it expired and now I only have BricsCAD Shape. BricsCAD looked fine, and critically it has a Linux version and offers perpetual licensing, but the licenses and subscriptions are all 50% or so more than equivalents from Alibre.

BricsCAD Shape: Direct, should have Linux version, but I haven't checked. Meant to take on Sketchup, and to be the free inducement to download the entire BricsCAD package. There's some power left here, as it's clearly just BricsCAD with various features turned off, but man I was having trouble doing sketch and extrude modeling, which is starting to feel more comfortable than placing primitives. You can do good stuff with this, but do more than the BIM-light sketchup clone they have marketed it as, there are some serious teeth to be pulled, including some stuff that ought to be simple requiring the console bar. You also have to do some things manually, like rejoin your lines into a poly-line that can be extruded into a solid. There's some there there, but frankly for general purpose modeling FreeCAD is a lot better Like many apps, it doesn't like to go crazy on compound fillets with acute angles, crapping out after a very gentle blend.

Salome Shaper/Open Cascade CADBuilder: Parametric and Open source. So here's one. It is not strictly a "CAD" program so much as it is the parts bench of a Finite Element Analysis package. I'm a liberal arts major, but I gather that it converts the part into a mesh (like an STL) and does various science shit with it (okay, I know a little more than that, but not much). So, you do need decent models for FEA, and a few years ago Salome rolled out a fully parametric part designer. It's comparable to the Part Design workbench in FreeCAD, and I think the default theme and icons look a little nicer, but it clearly shares a lot of code and basically it acts exactly like FreeCAD, except without the drawing and fabrication features, and it's a ginormous download that's a pain in the ass to install on Linux (easier on Windows). If you have it for some other reason, you should feel good about it, as it's not half-bad, but there's just not much point in getting it specifically to design for 3D printing. Oh, and then OpenCascade, the company that makes the 3d kernel used in FreeCAD, KiCAD, Salome, etc., lifted the Shaper module, half-assedly threw a ribbon interface on it, and compiled it for Windows as a proof of concept/sales tool that they controlled. It's okay, because it is Salome Shaper, but it's pointless and even more pointlessly, it's Windows only.

Creo Elements/Direct Modeling Express: Direct. The red-headed stepchild at Creo. It's free for any use, easier to use than BricsCAD shape, and makes an okay part. It also hasn't been updated in 4 years, has extremely limited export options, and I'm pretty sure they literally turned off the license server, so you can only use it by waiting for the request to time-out, ignoring the suggestion you might be behind a proxy, then clicking a button to open a webpage that gives you a 72-hour license key. I get the feeling it's on borrowed time. Points for still supporting the serial Spaceball. :-)

- Just a little bit of what dafuq

NaroCAD: Parametric, open source. Development stopped, doesn't really work at all, but that doesn't stop some asshole from trying to sell copies on eBay.

SelfCAD: Direct, online option. I just can't figure what they're offering that is better than a million different freemium models. Clumsy interface, but too weird to appeal to the total beginner. The only real benefit I see is that its free tier allows commercial use and its paid tiers are fairly cheap, though I'd grab DesignSpark or Alibre over this any day.

Form Z Free: Direct. No fillets or chamfers in free version. Full version is old fashioned and expensive. Seems like it's a small time operation just trying to hang onto its customer base. BricsCAD Shape and Creo Express are way better.

BRLCAD: Direct, CSG modeling, open source. I noped out after about 5 minutes. I am not a tormented E4 fresh out of Army drafting school with a head full of lies about how I'm learning valuable work skills, so I don't have to endure this.

gCAD3D: Is this real life?

BeckerCAD 14 - 3D Pro: Direct. Okay, so finally, here is the one I DID buy, for the whopping sum of $22, from a German shovelware site. I am pretty sure it was accidentally on sale for the price normally used for the non "Pro" version or maybe even the 2D version, and it's since gone back up to an unrecommendable $130 or so. The main claim to fame is that a couple of versions back, it was in a single HumbleBundle, and that led to a few reddit posts and one dude reviewing it on his blog. Here's what I can glean from the interwebs, including Goggle translating German CAD forums. It seems that years and years ago, there was a 2D CAD program that was modestly successful in Germany, but eventually it was outcompeted. The branding was scooped up by the shovelware company, MuT, but they needed working software to sell. So it seems they licensed an AutoCAD-like software called CADdy++, developed by a different small German company. The 2D module became BeckerCAD 2D, the full "Beginner" version of CADdy++ became 3D pro, and a few options were turned off to create the "3D". It's old, and it's quirky AF, but it uses ACIS, and the non-beginner tiers of CADdy++ are fully parametric, so there are "good bones" buried in the poorly translated menus. It uses a weird paradigm of of box-selecting everything with various built in filters, like there is the button for select-add, the button for select-remove, and the button for select-toggle, all in pride of place on the toolbar. Sketches are not constrained, though you can label them for actual drawing purposes with various constraints. Sketches are not tied to the solids after extrusion, but they also aren't consumed, so they can be revisited if the solid needs to be redone. The main place it shows its age/questionable provenance is with camera navigation, which best I can tell requires a hotkey, which I've mapped to a spare mouse button. Export options aren't great, but STL and various other meshes suitable for printing are in there, and you can export SAT files, which with one add-on, FreeCAD can import and save to STEP. Import is worse, though, where SAT is the only non-mesh CAD format supported, and writing those is a little trickier than reading them. Still, it's certainly been worth what I paid.

eMachineshop "CAD": Basically an interactive order form, but I did learn a little about sheet metal forming.

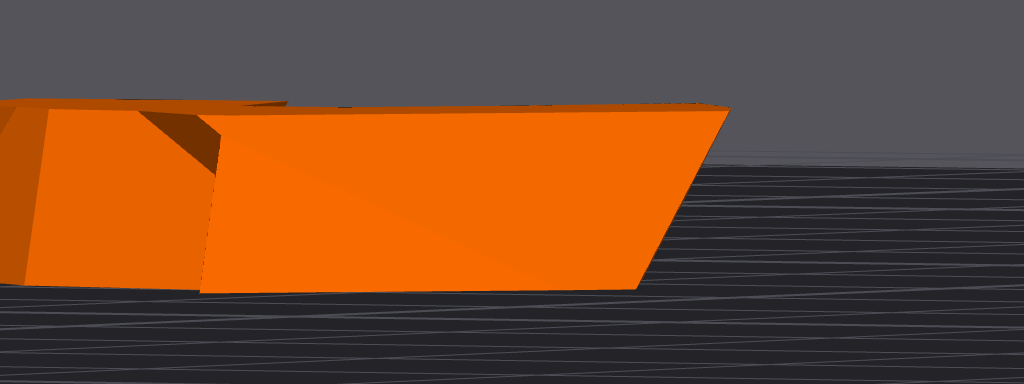

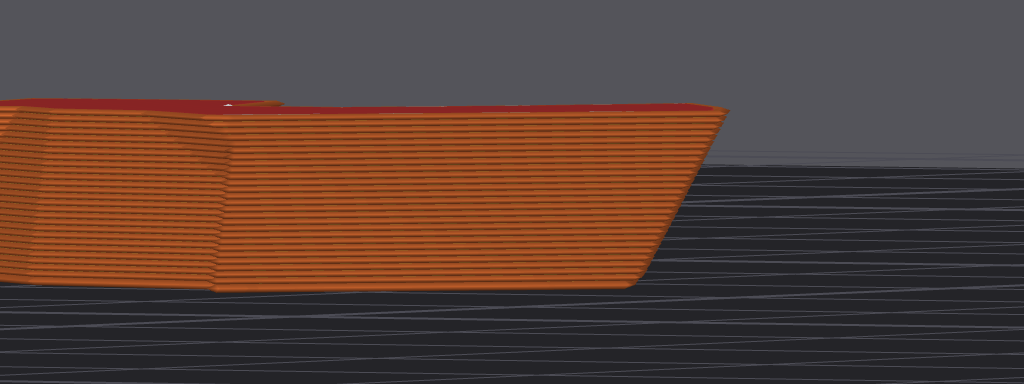

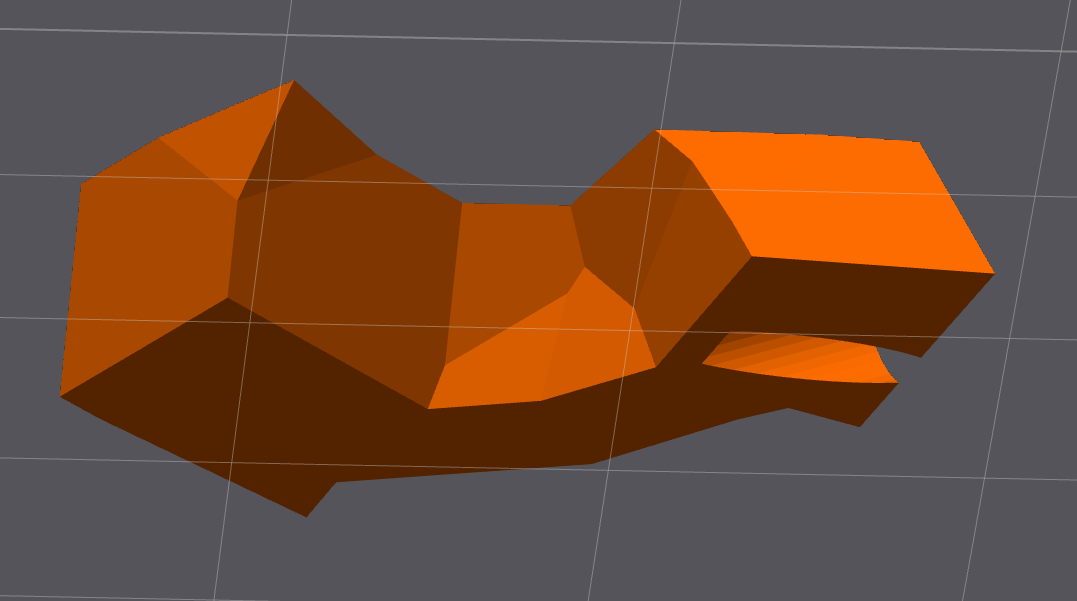

My first attempt at a commercial 3D print: an asthma inhaler body that can flip into a slimmer form so it doesnt jut out and dug into legs or tear pants. What do you guys think?

My first attempt at a commercial 3D print: an asthma inhaler body that can flip into a slimmer form so it doesnt jut out and dug into legs or tear pants. What do you guys think?