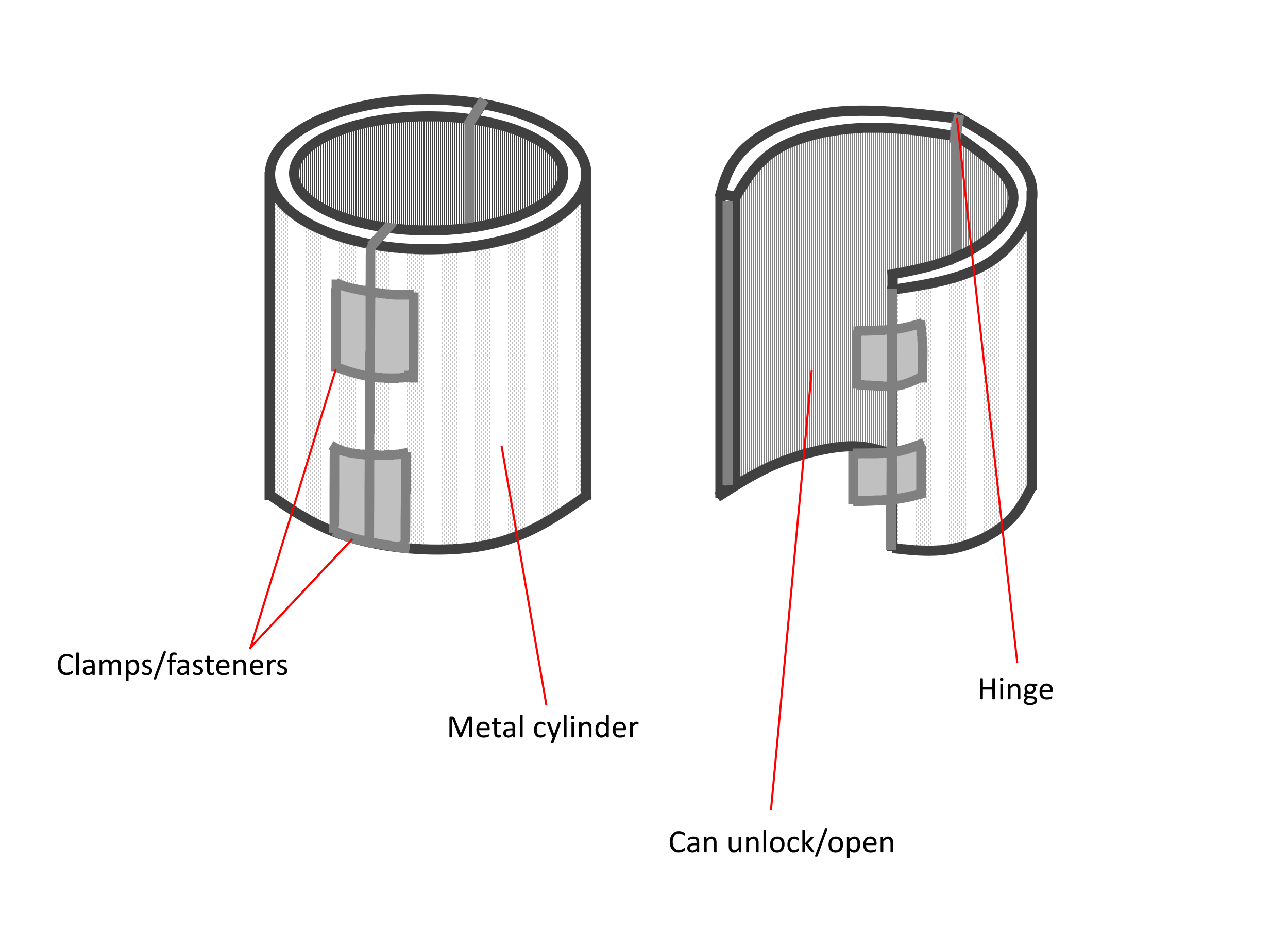

I use these at work. That is a sleeve style clamp used to seal off leaks

What is this thing?

Let us help you identify that mysterious object you’ve found.

Currently in CHALLENGE mode: If you've got something obscure knocking about, post a picture, and let's see how we do. Please prefix such posts with "CHALLENGE:" so we know we've got a fighting chance.

That's a "shackle" when you put it on a limb. I'm no plumber, but if that exists in plumbing, my guess would be coupling or bracket.

This sounds like it would accomplish what you need. Look up two piece shaft collar, or shaft coupler.

https://www.mcmaster.com/search?q=hinged%20shaft%20collars

Use McMaster to find what you need. You should be able to find a cheaper supplier using McMaster's terminology.

Clamshell clamps or Truss Clamps aren't exactly what youre looking for, but they'll work. Clamshell clamps are used in automotive and plumbing applications, truss clamps are used for mounting lights and speakers to stage trusses. You can get them cheap on amazon, and stacking several of them up works great for spacing shafts.

"Stroke Limiting Shaft Collars" are exactly what you're looking for, since they're designed to do exactly what you're attempting here but for industrial pneumatic or hydraulic equipment. Unfortunately since they're for industrial equipment, they can be stupid expensive and a royal PITA to find. But they do have a very silly name, even for hydrualic equipment (which is a field whose jargon is entirely made up of double entendre), which is a point in their favor. Also, many of them work very well as bearing surfaces!

PLEASE be careful messing with the cylinders in office chairs though. It doesnt sound like youre planning to, but just a blanket warning. Much like garage door springs, those cylinders store WAY more energy than you would believe, and fucking up trying to take apart a damaged cylinder can send the piston an impressive distance through your chest.

PLEASE be careful messing with the cylinders in office chairs though. It doesnt sound like youre planning to, but just a blanket warning. Much like garage door springs, those cylinders store WAY more energy than you would believe, and fucking up trying to take apart a damaged cylinder can send the piston an impressive distance through your chest.

In fact, if you look at the bottom of your chair where it sits on top of the piston, there should be a solid metal plate just above that. That metal plate is specifically placed there to avoid any surprise butt-stuff from a piston failing and rocketing up through the seat cushion. Because if that plate isn’t there, you will end up with a piston lodged three inches into your ass/taint area.

Thank you so much, those shaft collars look to be a much better design than the thing I drew (not much of a surprise to be honest!), I can stack a series of these instead of looking for one big solid one.

I didn't know that the cylinders were so dangerous 😬 I must have lucked out; I've had to use extreme brute-force methods to dislodge the old ones when it was time to replace them, pointing the thing directly at my guts and face while I work it loose with a hammer and spanner. Sounds like I was unwittingly playing Russian roulette with my chair. The difficulty I have in pulling out the cylinder is why I wanna just go with a "static" setup, it's way too much work and effort for something so simple. Now I can also add "don't want my cheekbones to get lodged in the ceiling" to the list of reasons to go static.

Thanks for the info and the warning!

No problem, I'm just glad all that time I spent memorizing the McMaster-Carr catalog finally came in handy!

The cylinders are sealed units, so they're safe to handle even after beating the crap out of them. The danger happens when people decide to repair a failing seal or leak and try to open the cylinder itself to get at the piston head - usually with a hacksaw....

We used something similar in this job I once had. We usually referred to them as "collar" or "clamp". In our procedures it was refered to as "clamping collar" to make it as little ambiguous as possible.

It was nicknamed "Dachs armor" as it was about the same length as the belly of a dachs hound, and roughly about the same diameter.

A pipe shackle is probably what you are looking for. If you get the wrong size and overtighten, it could deform the pipe and increase the likelihood of the pipe getting a kink and failing.

Sleeve.

Shaft collars probably the closest to what you're looking for that's easy to search for

"Manacle"?

I got some relevant results for "plastic clamps." Uline has a similar looking product listed as "plastic shelf supports for wire shelving units."

Kozyrev Mirror, you sit inside it and hallucinate other dimensions or something like that

Shit dawg, you holdin? I'll take 5 but I gotta pay you tomorrow.

It looks like a shackle.

Cable collar maybe?

Not quite the same, but a hose clamp would probably work

I made my own. My piston kept sinking on my chair, so I got some 40mm waste pipe I had lying around, cut it to length, then slit it once lengthways.

I put it over the piston (pulled the pipe wide enough to slide over the piston, not easy, but doable) and wrapped it with duct tape to stop it pinging off.

It is still there 5 years later.

Where'd you get that image? Did you draw it yourself?

I did 🤣 My skillz are known across the land. They call me the Paint.NET Bastard.

What about those metal bands that can be tightened with a screw? ‘Hose clamps’ I think.

That's a generic name for a Jubilee clip - https://www.jubileeclips.co.uk/products/original/

So a good idea, but OP is hoping to upgrade from this.

Ah yes. OK, I missed that detail in the text.

Mind you they’re only Jubilee Clips when they’re used to hold a King’s or Queen’s Jubilee together.

Otherwise they’re just ‘hose clamps’.

So I found products like you've shown on Amazon while looking to do the same for my chair but the cylinder on my chair is bigger than I guess "normal" ones, so what I ended up doing instead was using something apparently called a pipe nipple, like this one, that fits over the cylinder. I got the idea/process from this video except substituted a metal nipple like I linked above instead of a plastic coupling like they show. Anyway, it's been working fine for 9 months so far, just make sure you know how much height you want between the base and the seat for the length, and that the inner diameter (ID) of the nipple fits the outer diameter (OD) of your cylinder.

Here is an alternative Piped link(s):

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.

split muff coupling

Scaffolding sleeve clamp or Scaffolding sleeve coupler

Eh, make your own: short bit of pipe cut to length, split down the length, then held on the chair column with hose clamps.

I have used something like this on a chair with a leaky piston, there are ones specifically made for this purpose. They are plastic, and useless.

I suspect that using a metal one would last longer, but still fail, either by breaking itself, or by embedding it into the plastic of the chair on the top or bottom. I bet you would be more successful replacing the entire piston assembly with a stout metal pipe, but even that could break the piston seats at the top or bottom.

Penis-breastplate.