3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

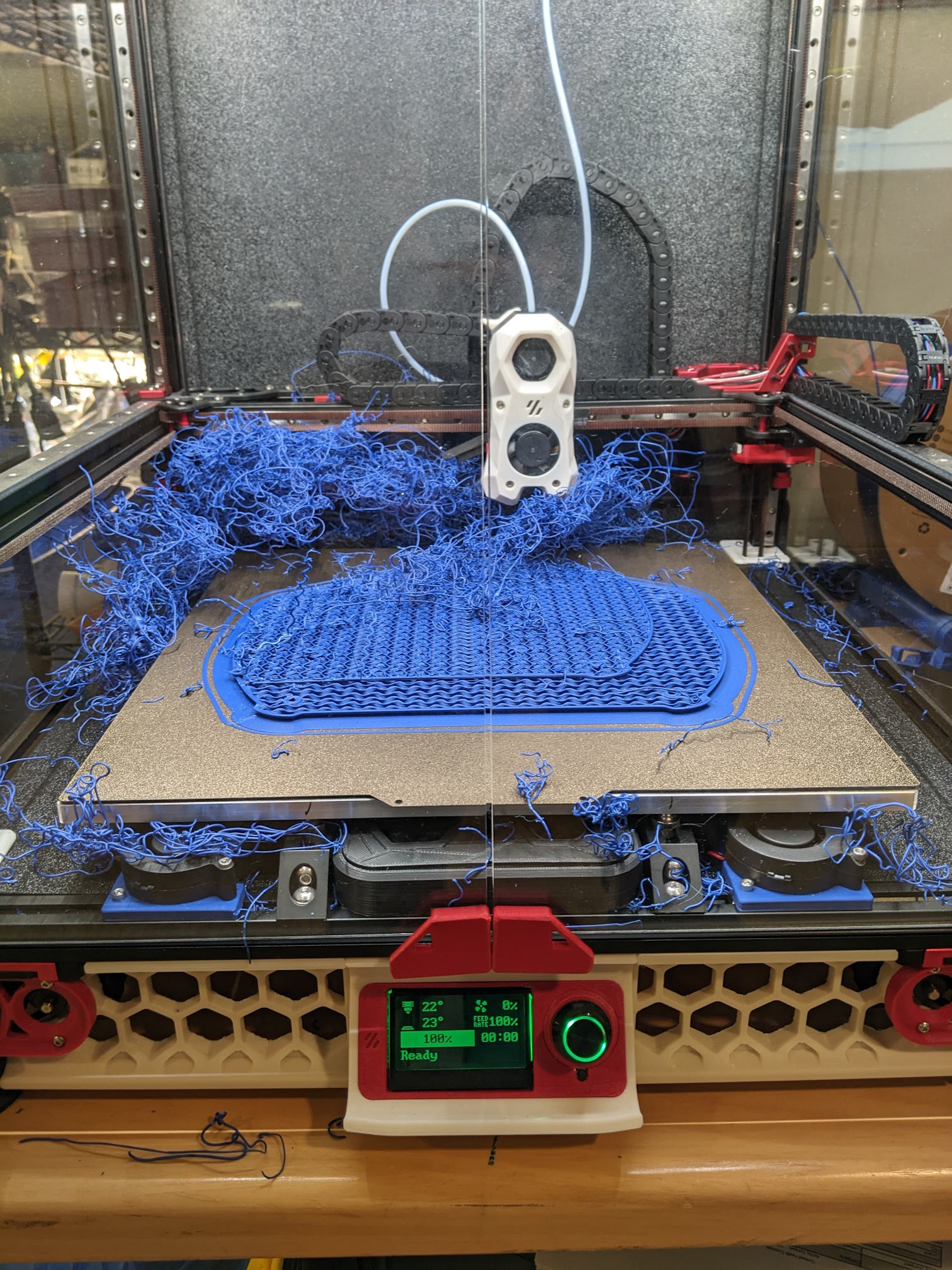

Bah, I typoed. I'm running 250 first layer/240 following layers, which is still lower than what most usually recommend. I was running 235 pretty consistently previously. I'll have to try printing a temp tower with the bigger nozzle. Here's one from the 0.4mm nozzle, granted also with my prior Rapido 1 (RIP).

Below 230 or so, layer adhesion was pretty poor

Above 245 or so, I started getting a lot of very fine/wispy stringing. It basically looked like ultrafine thread and would get itself stuck in my hot end fans.

Thanks to somewhat low chamber temps (350mm^3 printer with only acrylic panels), I've been keeping cooling somewhat low. I recently added some more bed fans to help my bed filter out, so maybe I can try a bit more if it starts becoming an issue.

Even 250 is a bit low for that high of a volume. Are you running a brass nozzle or a hardened/stainless steel nozzle? Steel nozzles will require even more hotend temp due to their low conduction rates. Eg, with the stainless nozzles on a Bambu P1S, I have to run ASA at around 260/262 for higher print speeds.

If stringing is a problem consider increasing the speed of your filament retraction (not distance) You may also want to turn off z-hop. Sounds wild I know, but it does help- by not lifting the nozzle during a rapid move, it "wipes" the nozzle clean as it moves off the part and reduces stringing. Realistically you shouldn't use z-hop at all unless you have a part with a very small cross section that keeps falling over when the nozzle wipes across it. Which ofc, the big print I see in the photo looks like it will have zero stability problems, lol.

@[email protected], replying to you as well here.

This is a hardened steel nozzle. 260 looked a little rough, but 255 looks pretty good. The temp tower got knocked off the bed at 235. It does look like I'll need to bump cooling a touch. Currently working on a retraction tower.

I'll have to give this a go after this retraction tower prints. On the last one I printed there was basically no difference on any of the settings once it got above 0.2mm of retraction. In my time with the rapido, any filament left in the nozzle will ooze out if its left hot but it doesn't string that badly.

Yup, I've run into this realization too - that's part of the reason why I was thinking to have z-hop on for this print

Adding two more bed fans, for a total of 4 (2 loose bed fans, 2 fans in my filter) and getting a bang on first layer (yay klipper_z_calibration) seem to have really helped with warping. I do have some ACM panels that I want to swap on to bump chamber temps up more, but I haven't taken the time to print new magnetic inserts for them yet.

Knock on wood...

I'm definitely going to try the retraction speed (instead of distance) and no z-hop in the morning.

Still try the higher temp, but bump up your retraction to counteract that. I went with the same move for printing silk to get cleaner layers, and it's worked out really well.