3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

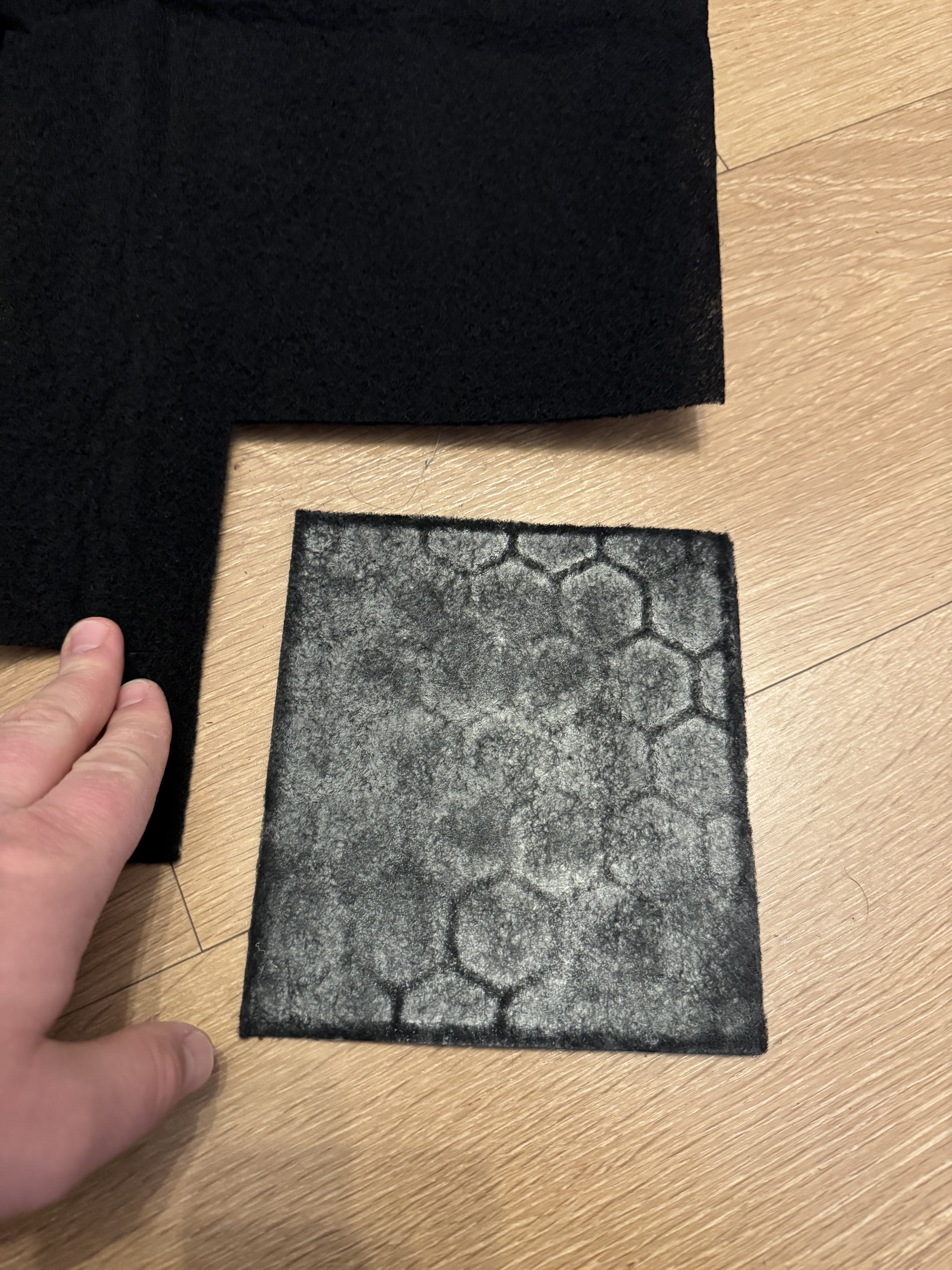

The charcoal filter in front of the HEPA one does nearly nothing afaik https://electronics.stackexchange.com/a/546074

Not sure how much this stopped, but it was definitely not nothing

stopped, but it was definitely not nothing

Most of what you see on charcoal filters are literally just dust and water.

Plus, nobody actually keeps up with filter maintenance. Charcoal filters sitting in free air are horrible for this. Charcoal filters have a saturation time as a function of mass

I was looking into fiber laser safety for ABS vaporization for my company and came across a few studies (can't find right now).

Activated charcoal filters in free air become saturated after like a week or so of use just because of the fact that they absorb both the tiny amount of unwanted compounds along with massive amounts of common air particles. You really need an enclosed container with butterfly valves like the Weller units https://www.weller-tools.com/us/en/filtration/products/solder-fumes with heavy carbon filters along with other absorbers in order to not completely saturate.

After the first week, the "solder fume extractor" filters are literally just collecting dust. Your charcoal filter looks exactly like my mesh computer dust filter in the picture as far as what it caught.

I’m using it with no high expectations as in „it’s probably better than nothing, and the fan pulls some of the fumes away from me”. As for ABS (which I’m printing VERY infrequently) I’ve printed Bento Box for my printer (from ABS of course) and haven’t actually mounted it on my printer yet (because I print with ABS/ASA so infrequently);) Besides that my printer sits in a boiler room which (like the rest of the house) is actively ventilated using a recuperation system.

This one looks way denser to me than OPs and the one from stack overflow. (but I may be wrong)

Thanks for sharing the photo, it definitely looks useful!

Well, that makes me feel better! I have the parts to make a charcoal-only filter but was too lazy to assemble it before doing a big soldering project recently, choosing to just open the window next to me instead. It's nice to know that it would've been useless anyway, so my laziness didn't actually cost me anything.

Charcoal is a smell filter, it's why it's used in front of a HEPA.