Hi folks, this is a follow-up to my previous post here.

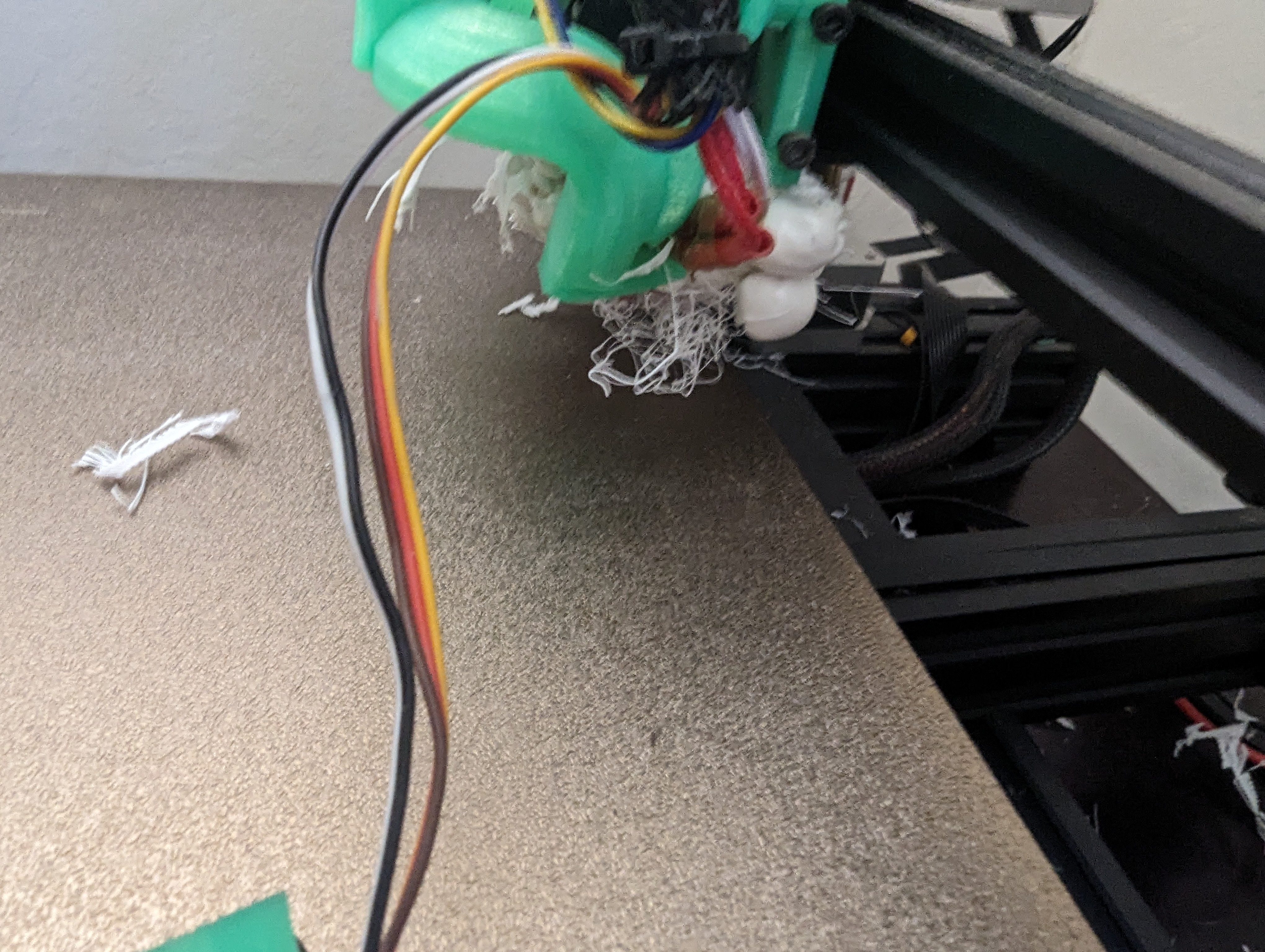

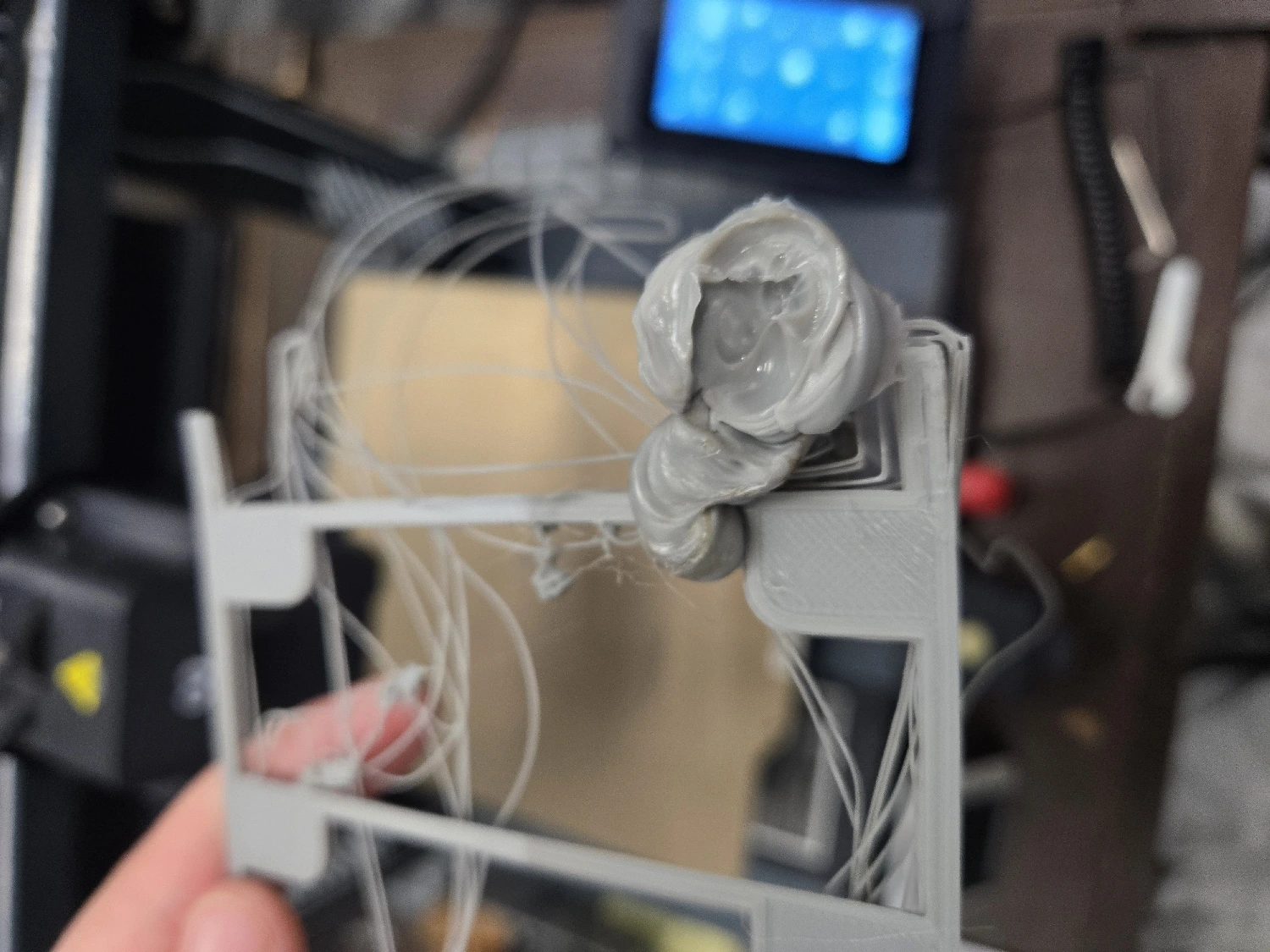

To briefly summarize, when upgrading Cura from 4.12 to 5.6, my printer and slicing profiles seemed to transfer over automatically, but when I tried to slice and print, I encountered a strange issue: It no longer heats the extruders or the bed. It just starts "printing" immediately with stone-cold extruders and bed.

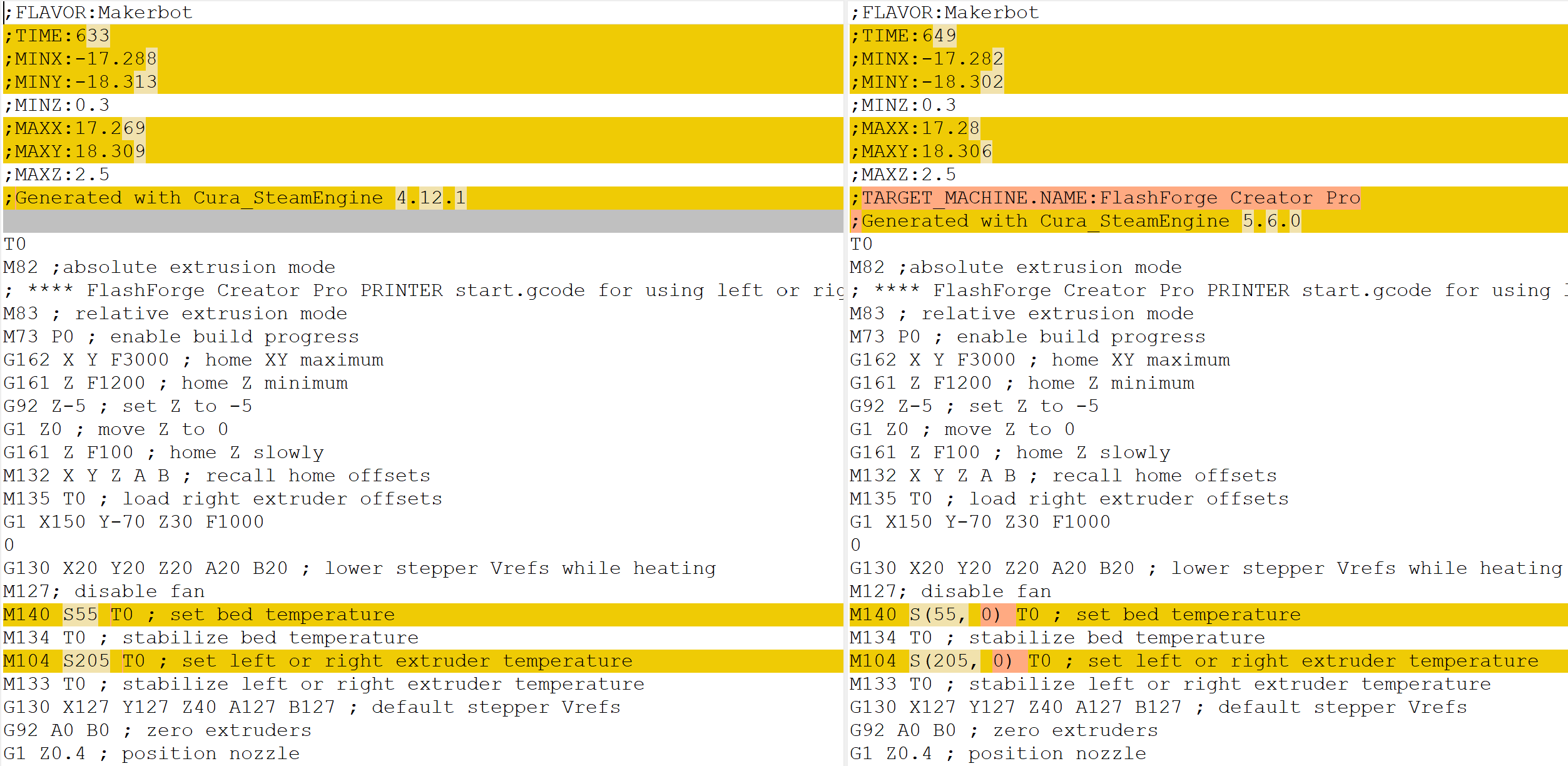

Thanks to some suggestions under that post, I've narrowed down the problem to a couple of lines of in the start gcode (located in Settings > Printer > Manage Printers... > Machine Settings).

Cura start gcode:

M140 S{material_bed_temperature, initial_extruder_nr} T0 ; set bed temperature

M134 T0 ; stabilize bed temperature

M104 S{material_print_temperature_layer_0, initial_extruder_nr} T{initial_extruder_nr} ; set left or right extruder temperature

M133 T{initial_extruder_nr} ; stabilize left or right extruder temperature

While the start gcode is identical between 4.12 and 5.6, it seems to be written differently in the output file.

Cura 4.12 output gcode file:

M140 S55 T0 ; set bed temperature

M134 T0 ; stabilize bed temperature

M104 S205 T0 ; set left or right extruder temperature

M133 T0 ; stabilize left or right extruder temperature

Cura 5.6 output gcode file:

M140 S(55, 0) T0 ; set bed temperature

M134 T0 ; stabilize bed temperature

M104 S(205, 0) T0 ; set left or right extruder temperature

M133 T0 ; stabilize left or right extruder temperature

I think I've identified the problem, but don't fully understand the reason. Cura 5.6 seems to copy both the temperature and initial_extruder_nr values, and places them in parentheses.

Could this discrepancy be the cause of the bed and extruders not heating?

What is initial_extruder_nr, and what does it do?

According to the fieldofview Replacement Patterns site, it is "the first extruder train used for the print". This doesn't sound like it is related to bed temperature.

Can I delete them from the temperature lines in the start gcode, or could this cause other issues?

Thanks in advance!

Edit: Whoops, this is embarrassing.

I just realized that sawecw commented two months ago on my original post and came to similar conclusions. I'll try Cura 5.7.

Edit 2:

I have upgraded to Cura 5.7, and can confirm that this bug has been fixed.