Very nice. I want something like this go a computer monitor I could use at a desk and in bed (partially disabled). There is so much to this it would probably be useless to waste time writing it all out, but if you have any key lessons or tips, please share them.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

There's some pretty good gas spring monitor arms, I use a few at my desk. The one I use for a fairly heavy 27inch monitor might fit your use case but they can get pricey. https://www.ergotron.com/en-us/products/product-details/45-241#?color=polished%20aluminum&attachment%20option=2-Piece%20Clamp

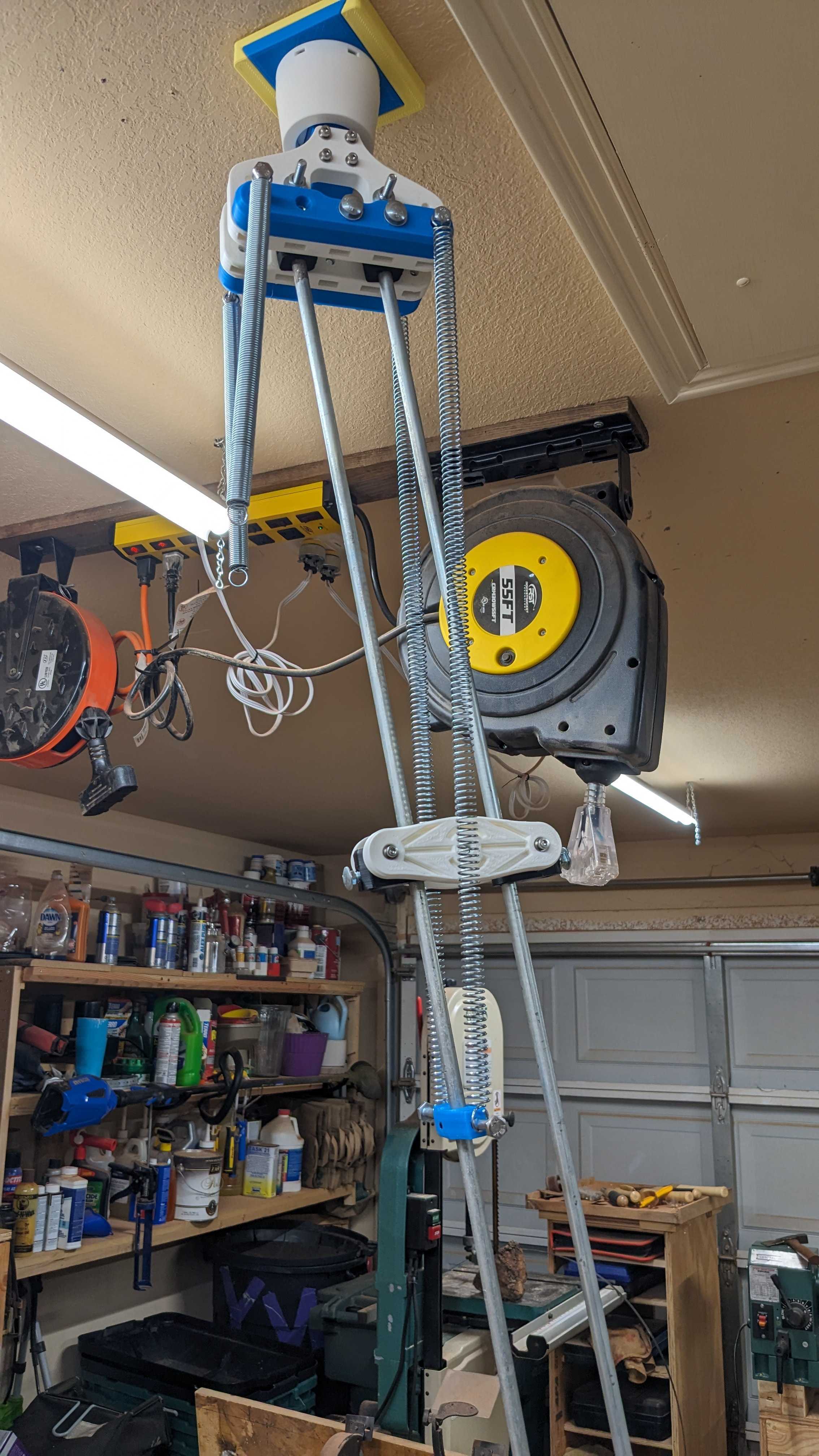

The springs I used here might be a bit weak for a monitor, I think the long ones are four pounders. But I don't know much about springs and I just got ones that looked right from Lowes :)

As far as tips from this build, being able to change configurations and adjust positions did a lot to shore up the gap between what I wanted to do and how little I knew about any of this. Also, I'd probably do a 90 degree bend at the middle link.

Are you planning on motorizing it or just setting it manually?

Just manual, it only needs to be moved into position and remain there for my purposes.

But I have been tinkering with a camera slide made from almost all 3d printed parts that will be motorized (when I get around to it lol)

I've always wanted to make something like a Glados model on a moving extension, with a built in mic+speaker+camera. :-)

This thing is awesome!! It can go anywhere! See anything! This is so cool, and I love also how when you use it you won’t have tripods getting in your way. Oh!!! And you can pan it!!

I greased the captured post that it spins around and I've only almost hit myself with it a couple times.

For the upper arm, will it eventually use all four springs or do you alternate the pair based on the direction you want it to lean?

I know this is way later and doesn't really matter, but I really liked your idea and thought about it for a while.

I ended up coming up with this spring "quick caps" for quickly moving, rearranging, or de-tensioning them for maintenance and it has really improved how the whole boom operates.

Anyway, thanks for the idea!

Those quick releases look great. Simple solutions are sometimes the hardest thing to come up with.

Originally I was using all four, but after working with it a bit and changing the springs orientations I found it worked well with just the one set. I've left the other two in case I change my mind :)

Now you've got me thinking of some sort of quick release system for switching these in case I do want the lean direction to change..... That would be super useful.

That looks awesome! Although, a little spindly.

The rods are 3/8ths inch and the bolts are 1/4 20 hardware, plus 4mm machine screws assembling smaller parts and as grub screws. I think it'll stay together fine, but there's enough load over a long distance that it does have a little sway and bounce after moving it. Although, after a few seconds it settles and I haven't had any issues. I figure that my phone's video stabilization will filter out the small stuff.

Oh yeah, and I printed the components with an 0.8mm nozzle and 0.5mm layer height. They're chonky.

Did you by any change get inspired by Marius Hornberger? :)

https://www.youtube.com/watch?v=7V0NvNZmvXU

He did something very similar, your's looks a bit better with the lighting

Here is an alternative Piped link(s):

https://www.piped.video/watch?v=7V0NvNZmvXU

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.

Weirdly enough, yes and no.

I assumed you were linking this video: https://youtu.be/p68Y1e4acF4?si=vS-Dpx9isLgJdFHX

Which is where I thought I was pulling inspiration from, though I'm sure I watched his gantry video and had it sitting somewhere in my mind. I totally forgot he did basically the same thing hahaha.

I also ~~ripped off~~ took inspiration from Inheritance Machining's: https://www.youtube.com/watch?v=t1sXvMY_vAw

And a smaller YouTuber I was talking to had a small series doing some things with 3d printed camera arms: https://www.youtube.com/watch?v=fble2ifR0NI&list=PLNQ9UrHMNMNhJP1yVZK1tsiatytQrkfFw

Here is an alternative Piped link(s):

https://piped.video/p68Y1e4acF4?si=vS-Dpx9isLgJdFHX

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.