3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

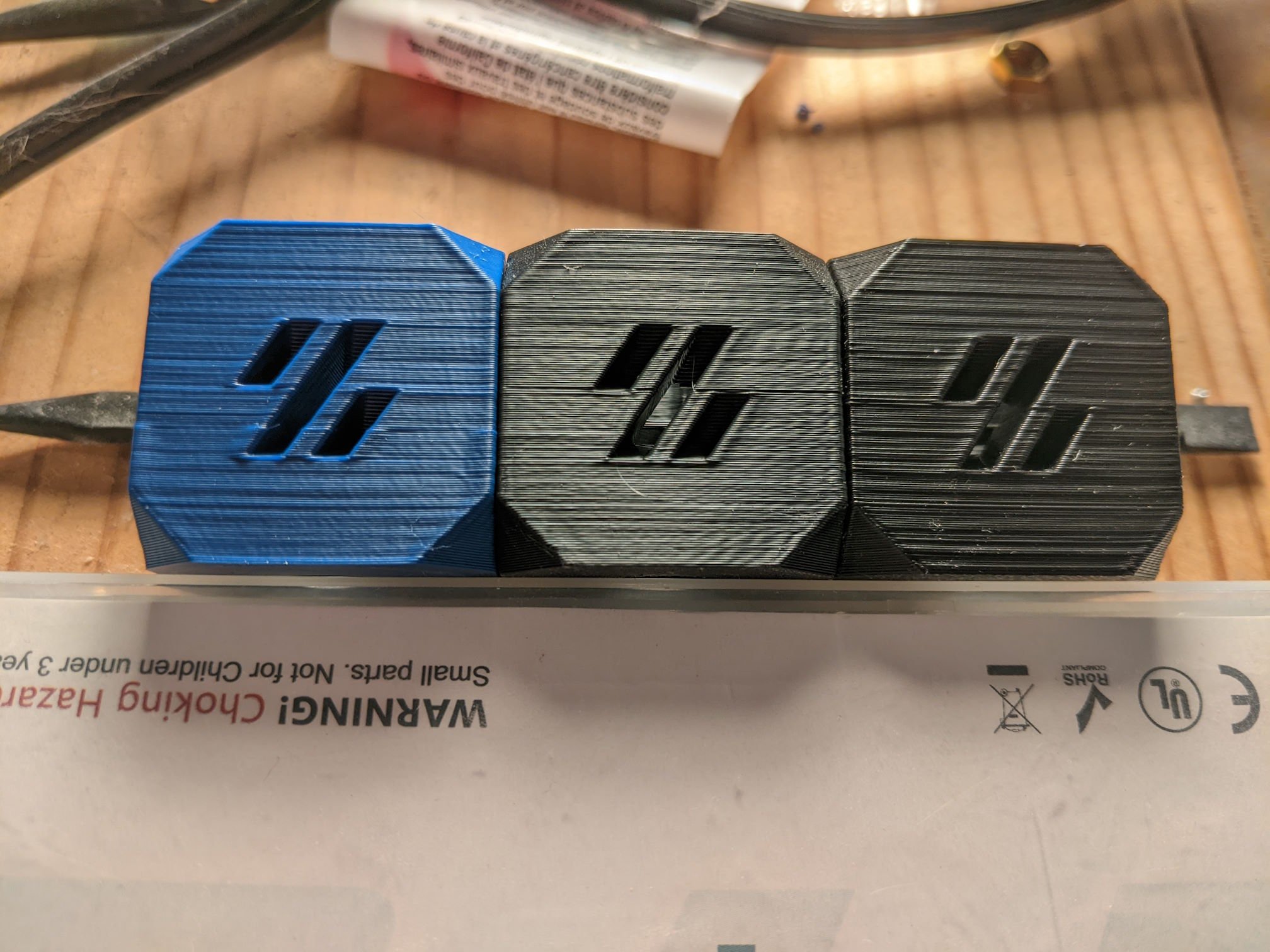

What do you mean? The quality of the cubes themselves or the surface finish? There is a bit of skin defect going on and it looks like OrcaSlicer introduced some corner rounding about 1/3 of the way up the blue cube. I still need to run input shaper, but the prints don't seem that bad? Maybe my standards are low s because of the absolutely appalling quality of my old I3 clone.

This is also intentionally pretty harsh lighting. I just added the OP to add a photo with more diffuse lighting and all three prints look way more like what you'll find on the web.

The inserts are poorly inserted and into oblongated & incorrect ID (too big) holes, and the print quality looks poor (just low quality printer likely). Doubt those shafts are perpendicular or located accurately. But I’m not looking at this from a hobbyist perspective, but from a mechanical engineer, machine designer perspective.

Cheap printers are a waste of time IMO, but a good engineering learning experience

Thank you for the more detailed reply. The part in question is is a Voron Design Cube. I printed it on my 350mm Voron 2.4. The print does match the source STL fairly well, but it does look like OrcaSlicer's result (blue) has more corner rounding than the SuperSlicer results. There's a 45 degree chamfer on both the lower and upper face of the Z, which might contribute to what you're seeing. The parts themselves are also physically not that large, so you might be seeing a bit of the impact of the nozzle being round too.