3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Glad you found it. It's been a feature for over a year or so and maybe longer now. It was driving me crazy before the patch, for sure.

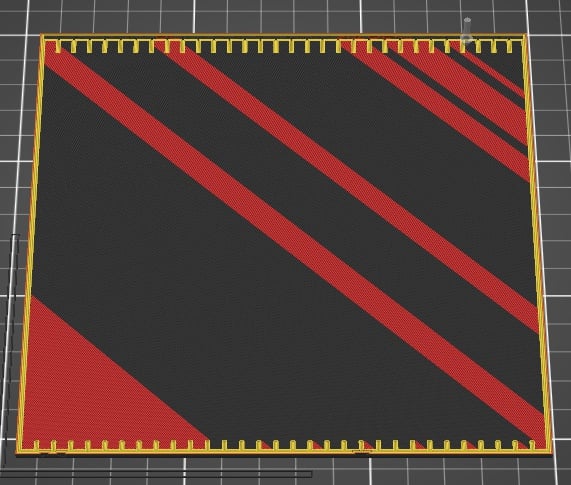

I am willing to bet that your object is confusing the slicer fairly bad, or at least, making the original issue you had look much worse. Any path optimization got destroyed by those comb-like features, I bet.

The downside to this (especially if your PID tuning is off) is that continuous printing of a large top layer can suck a ton of heat from the nozzle. In the worst cases, you get a jam and risk grinding your extruder as the filament stops melting fast enough. The "normal" mode of offset lines gives the hotend a bit more time to recover between sections. (I believe Revo-style hotends mitigate most of that problem because of the uniformity of heating.) Still, this problem is fairly rare but it has happened to me on occasion.