3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

So both Klipper and Marlin+Octoprint use a Pi and an arduino (in simplified versions, the SBC and the MCU can be any boards but I’ll use those brand names to make it easy).

Marlin uses the Pi to display the web interface, then sends the gcode to the arduino. Then the arduino does the math to convert the gcode to motor commands. Gcode.

Klipper uses the pi to display the web interface, but it also takes the gcode and converts it to motor commands in the pi and only sends those simplified motor commands to the arduino.

So with Klipper the arduino doesn’t need to convert gcode which is a pretty intense computation. Also, gcode is actually pretty heavy to send vu serial over usb in Marlin and often the printer can print faster than the gcode can be sent. Which results in hang ups in the print, the printer pauses, especially in a print with a lot of curves and printing fast. Klipper can use the full power of the pi to make intricate motor commands, fine tuning acceleration and all to avoid vibrations (input shaper, it even uses an accelerometer sensor to refuse vibrations making cleaner prints and quieter printing)

Other benefits of Klipper, settings don’t need to be flashed to the arduino, they are saved in a text file on the pi. Changing Config is a simple text edit, then reboot to apply the changes. You can edit the settings right in the web interface.

One of the down sides of Klipper was that you had more functions in Octoprint with plugins, that’s not true anymore. You have many plugins compatible with Klipper with Timelapse exclude area, remote access, Obico (the spaghetti detective), and so on.

The web interface is much lighter and responsive than the bulky Octoprint. Octoprint was an afterthought while Mainsail was purpose designed for Klipper.

I used to run Marlin and Octo and hated the experience. Since I tried Klipper I can’t go back.

Thank you for the explanation!

You’re welcome. There is a lot more than that even. When you start digging through, Klipper allows you so much control. You can even have your printer run shell commands (deactivated by default because it so powerful, it can be dangerous if you don’t know what you’re doing)

You can control RGB LEDs and more. You can also connect many arduino isntesad of just one

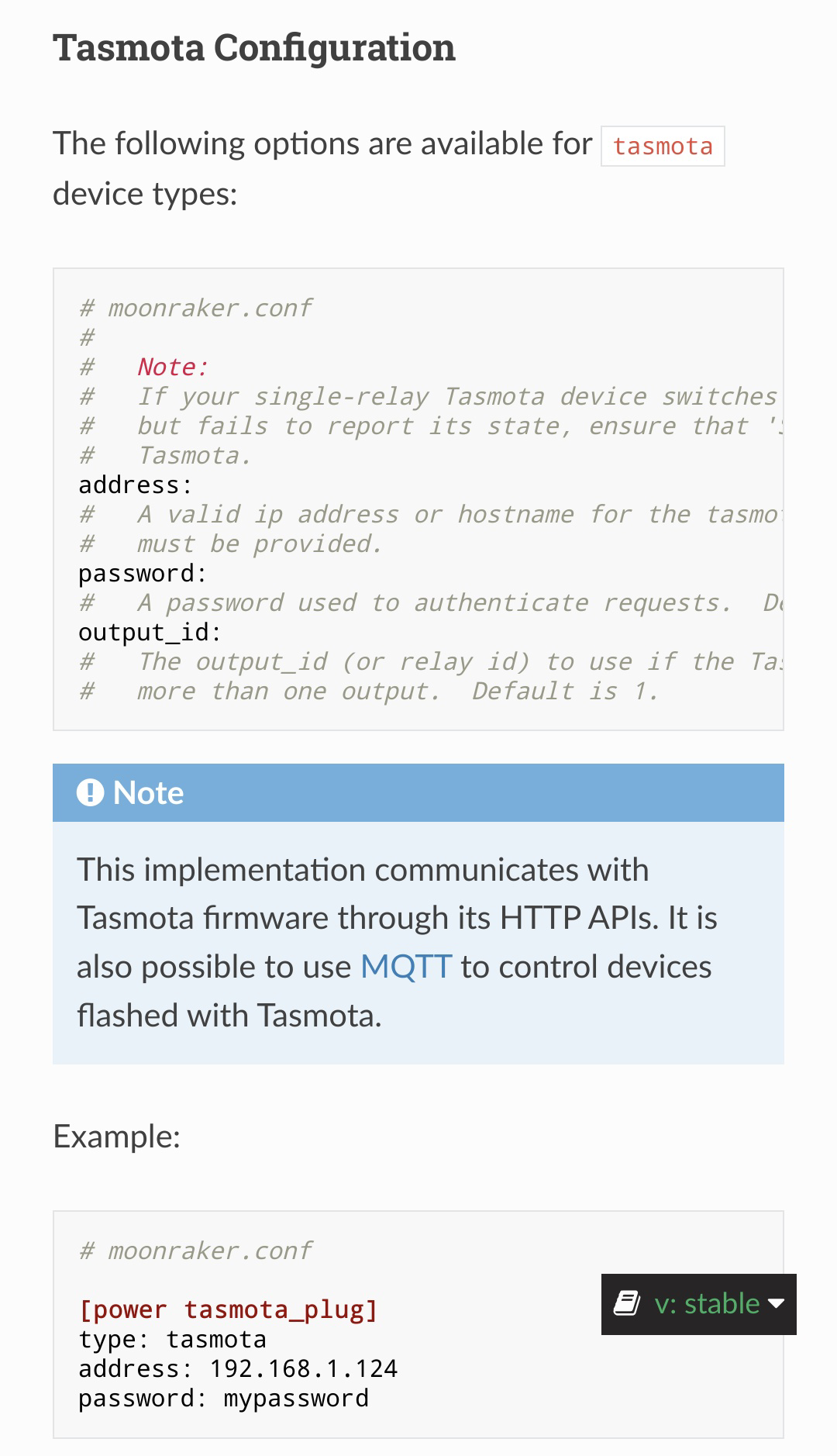

First of all, I need to fond out how to control my tasmota switch to turn on/off my printer and my led...

Are you running Home Assistant? Klipper/Mainsail has an integration for HA that will allow you to control your printer with it. You could use HA to control your Tasmota devices too.

No I'm not, but i'll found a way

Looks like what I'm looking for Try it tonight

Tasmota is natively supported by moonraker

Yes! I get it working this weekend, thanks!