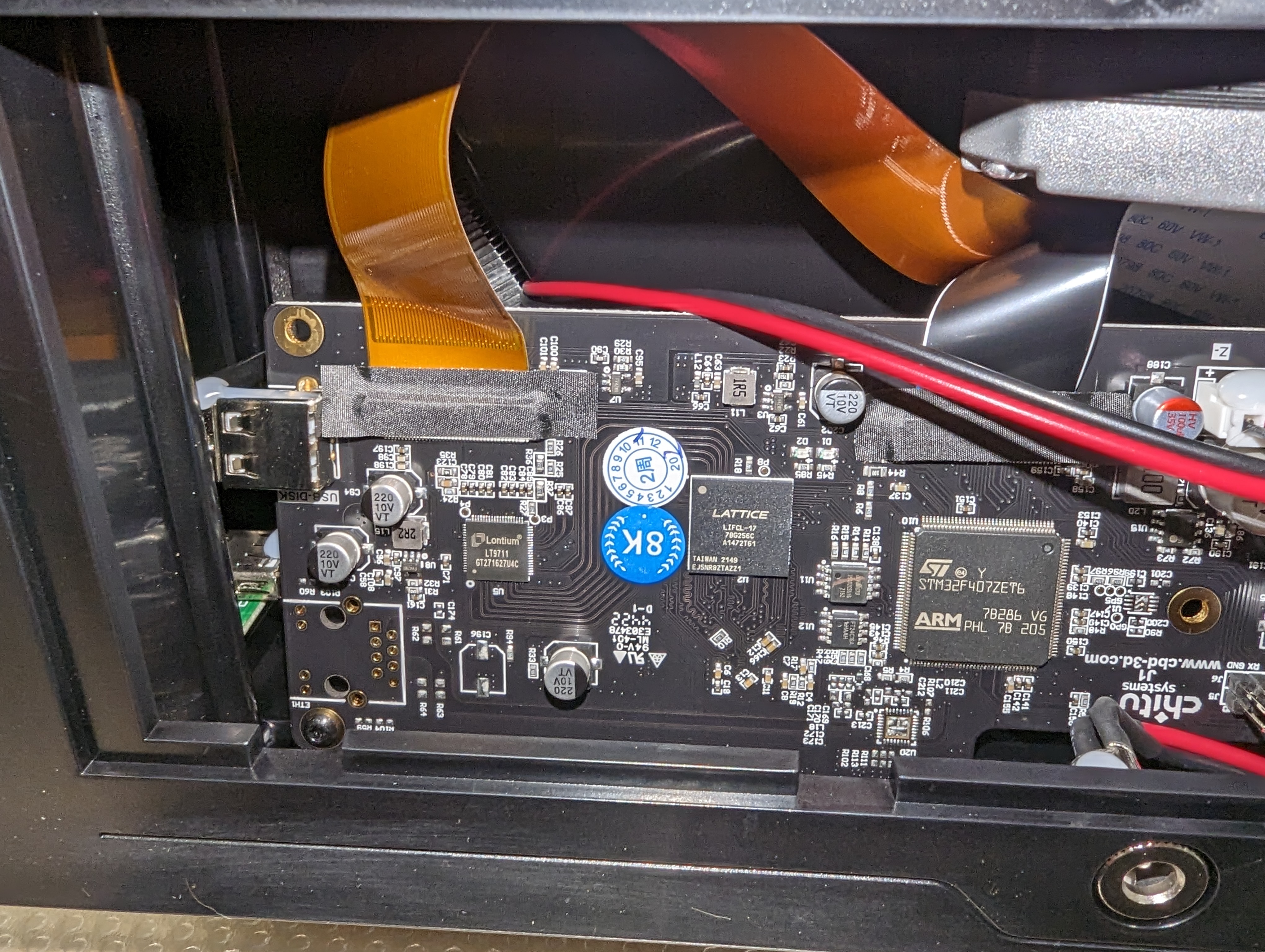

The main issue with all of these resin printers is the proprietary displays all have NDA locked documentation. This is the main reason they can't be supported by the community at all. This is one of those situations where reverse engineering the API and protocol for the display requires a serious professional level electronics lab where anyone that can afford the kit, can't afford the time, and it isn't worth it for just one revision of a display in a product that could be changed at any time without warning.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

That's a good point. Although I would just replace it with a Nextion display. IMO, the interface isn't that great. I don't really need to see the thumbnail either, just some basic maintenance functions and a progress indicator directly on the unit. Once we have network connectivity, we can build a far better interface via a web interface a la Octoprint.

Hm, interesting that the board has a solder point for an ethernet jack, but I see none of the usual "support" components near it that are typically also required (a PHY and/or network chip). Could be that that's supposed to be run in software on the MCU, but that would require that the firmware supports/includes it.

It's there because these boards are mass manufactured by chitu systems and shoved into almost every singe popular resin printer out there. They can be customized depending on what features the different manufacturers want for each model.

This is half solution, but still might be useful if there is nothing better available. There are wifi SD cards like toshiba flashair that can connect to your wifi and provide samba share folder (with some easy moding). Then you can save gcode directly from slicer and start the print from printer screen. Far from octoprint features, but still beter than moving sd card every time