3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

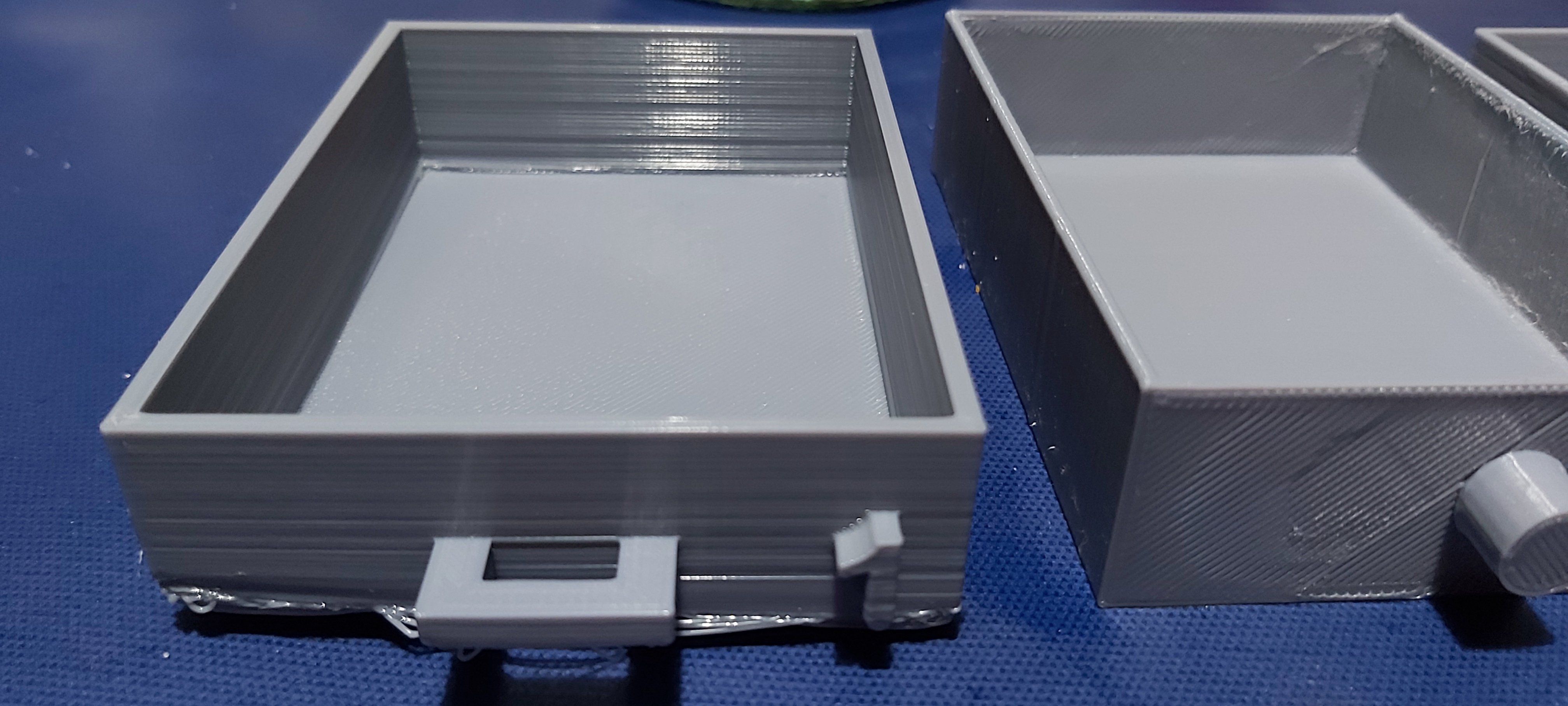

Pointy corners like to lift. Try designing with a small radius if possible. A brim helps a lot. Also print so that the long edge of the part is on the X axis for bed slingers.

This is an example I am currently printing with a 10mm brim:

Why on x? I haven't heard this before

The shorter side on the X makes less air movement across the bed thus retaining more heat in a localized area. Think of all printer motions like little fans themselves. Moving a palm frond or paper fan moved in a large motion moves more air.

The moving bed and undesired cooling it causes is one of the largest weak spots in Cartesian printers.

So on a bed slinger you can orient a print any way you want.

But, a bed slinger has a lot more mass to move when moving the Y axis (the bed, your print attached to the bed) then it does on the X (the gantry and tool head)

So orienting your print where longer moves are on the X axis has a couple benefits

You’ll see something similar with Voron prints where some orient the infill to be at 45 degrees since that overall works best with how CoreXY AB motors work. E.g. only one motor is pulling vs both working in tandem at other angles.

https://github.com/AndrewEllis93/Ellis-SuperSlicer-Profiles?tab=readme-ov-file#45-degree-profile-vs-standard-profile

That depends on the type of print. The design the OP showed will not have such a ringing issue with something large and low. The problem is a lifting corner. The long Y orientation is wrong for this problem.

I'll try to work that into my next iteration, not sure if rounded corners will help with the plan in mind but that's all part of the challenge and fun I suppose! Thanks for the response.