3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

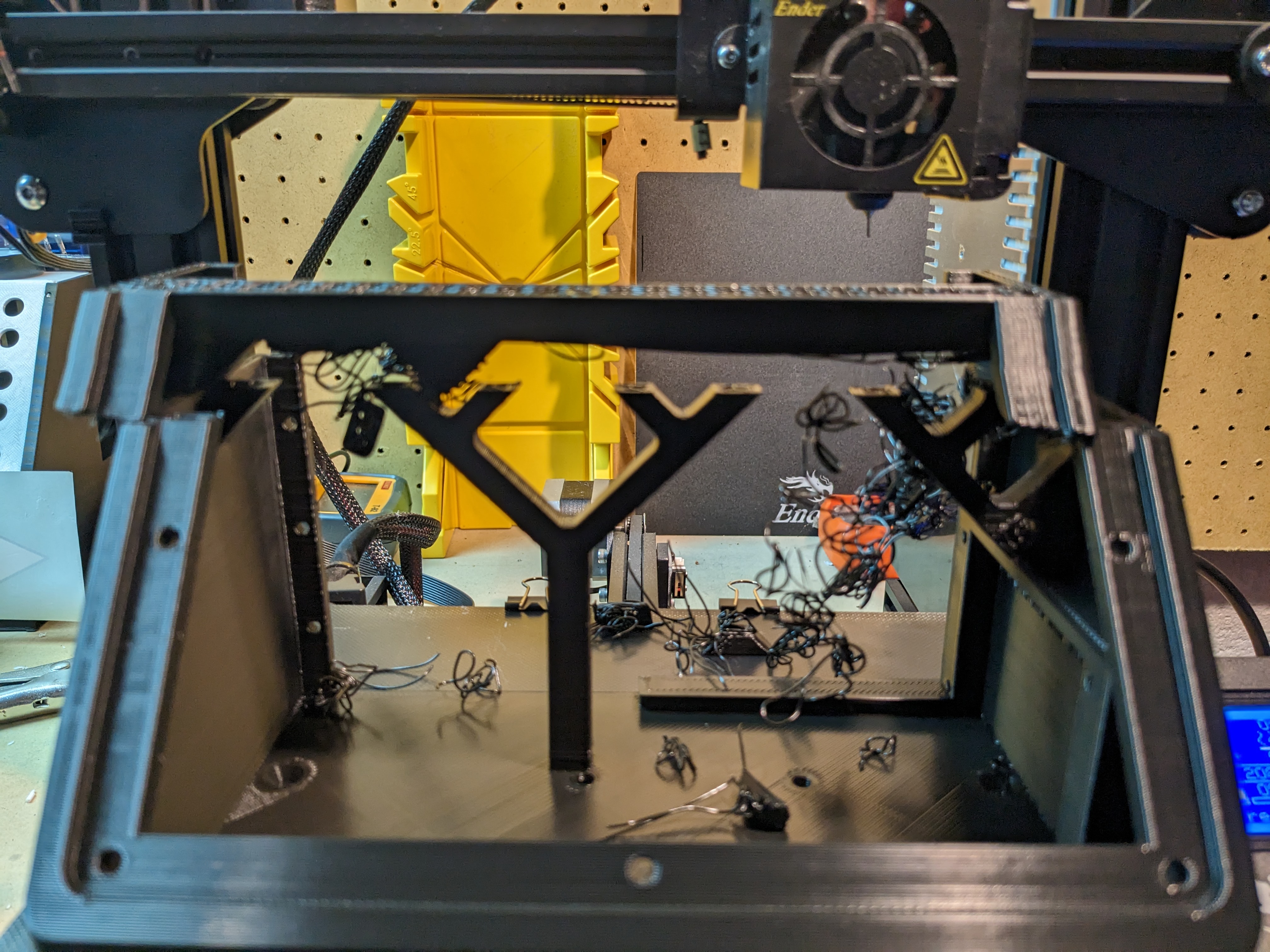

So... just to clarify, you've ruled out loose belts?

working backwards-the first thing to check is your belt. Assuming the belt is fine, how is your accel and jerk setting? Id assume those are okay-ish out of the box, but it's worth a look. a fast move coupled with a slightly too-loose (or too-tight...) belt could hurt things.

From there, I'd check to see if the nozzle was dragging/catching on anything. (look at the failed print part. you might see nozzle marks. or see where it started.) depending on what material you're printing on, warping could raise the part up high enough to drag the nozzle, causing slipage in the belt. if it got stuck because the part was obstructing the nozzle, then it'd resume when it got high enough to clear it, but with having lost the x position.

filament unspooling poorly- regardless of what causes it to do so- that would likely have stripped out the filament at the extruder's hobbed bolt. you can test that by holding the filament from unwinding while it tries to print some. You might also be able to see filament powder/chewed bits around your extruder.

Edit to add: is this a Bowden rig? A Bowden tube maintains the length (and length of filament inside it,) without regard for the x position, so it would be difficult to see how a stuck reel could cause a layer shift,

as a side note, you might be able salvage the print by measuring to where the height to where you lost the print, splitting the part at that height and starting a second print there. then, glue the new part on with some coarse sanding and CA glue.

Thanks for the tips, and the clarification that spool catching can't cause this sort of issue with a Bowden setup, I missed that nugget of info! I posted in other comments, but I think it was definitely a catch and loose belt. Surprised that the loose belt didn't cause problems throughout the print, but maybe I've just been getting lucky all this time!

I'm willing to reprint the entire thing for sexy smooth lines. My manual handicraft of sanding, gluing, painting, etc always leaves me disappointed in the final result 😂

Again, thanks for the help, much appreciated!