3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

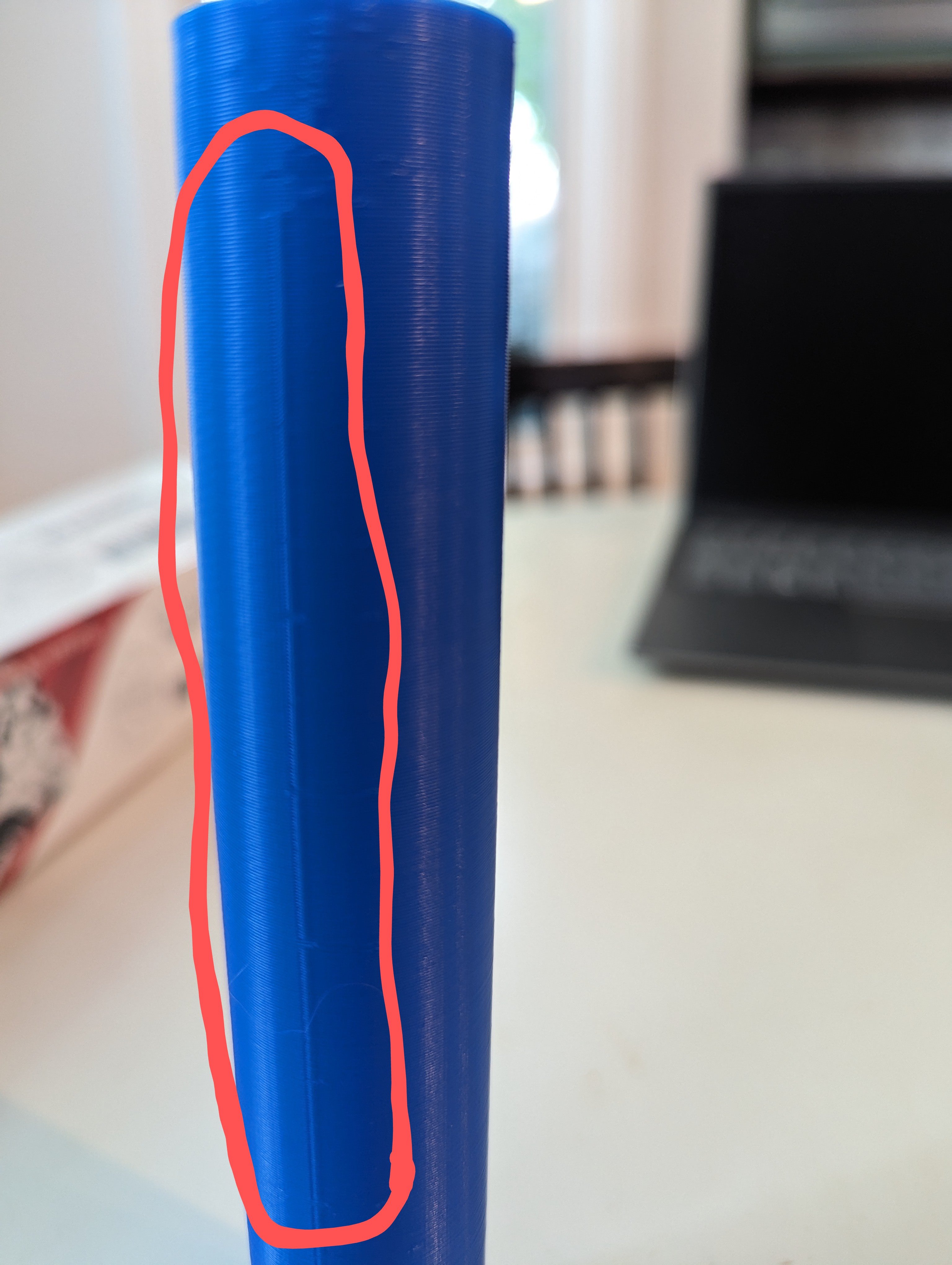

Good to know for future prints. Thank you. This particular part of for a toy sword for my son, we're learning this hobby together so I appreciate the insight.

You can also look into a setting, I think it's called coasting. It will reduce the amount of plastic extruded towards the end of the layer to reduce the seam, but keep in mind this will look better but probably have less strength at this point

I highly suggest a few YouTubers that go into things like this, like makers muse and teaching tech

If you’re going to paint it, take the opportunity to sand the Z seam off before doing it