3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

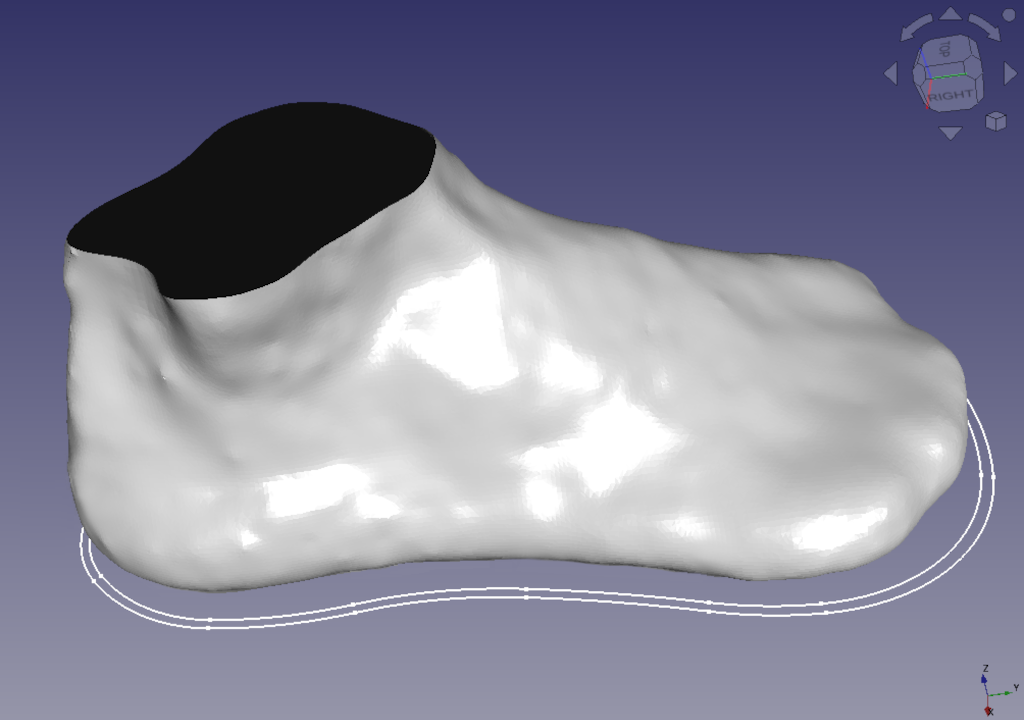

I'm starting to wonder if I might be better off printing a mold out of PLA and pouring liquid rubber into it 🙂 I mean technically, the shoes would be 3D printed and it would probably create fewer headaches, because liquid rubber is what I use now with regular molds to create my shoes, and it works perfectly fine.

I'm a bit concerned that this whole endeavor will results in quite stringent requirements in terms of hardware, and difficulty in manufacturing, because ideally I would like my design to be reusable in developing countries for others who have a need for custom footwear like I do but don't have the money. My plan is to turn my FreeCAD design into a configurable OpenSCAD file eventually, that anyone with an el-cheapo printer and some time can use to make cheap bespoke shoes.

So maybe for cheap easy shoes to happen anywhere in the world, maybe a PLA negative and liquid rubber is in fact a better route.

But for now I'll go with the TPU: I have it so I might as well, and I'll learn something.