3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

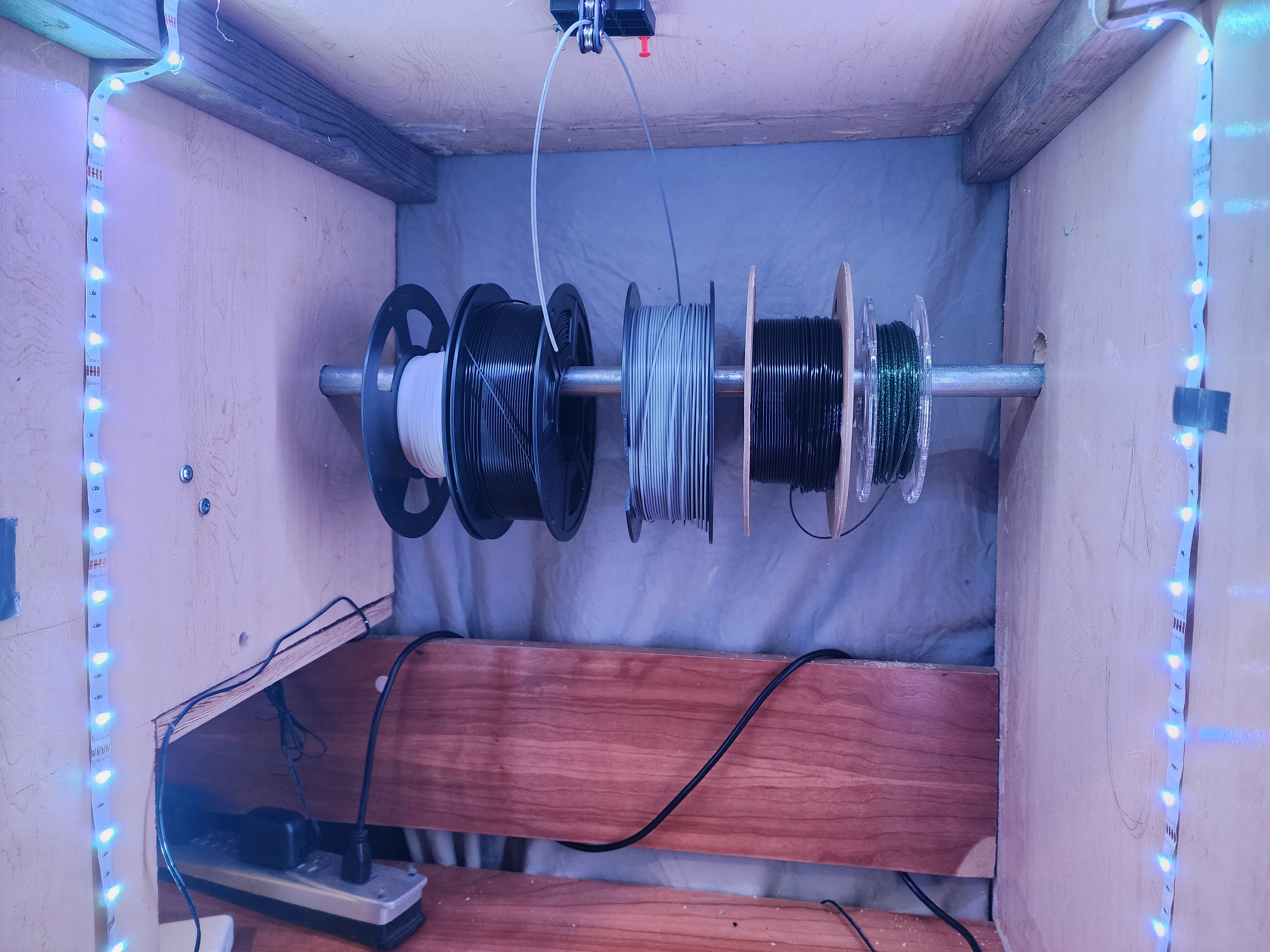

You must live somewhere dry. I have to keep my filament in a box with silica gel.

I've never really had issues with wet filament. I primarily print in PLA, and while it's a pretty hot button debate, I lean towards the evidence of PLA not being effected by moisture. A user here ran an experiment and posted the results of leaving a spool of filament in a bucket of water for 24 hours and the running a print with it still in the bucket, I think they just put a sponge in front of the filament guide to get rid of the water droplets but it printed exactly the same before and after the soak. Ever since I saw that, I haven't bothered with bagging or drying any of my PLA outside of printing with it inside the enclosure (where humidity drops to single digit percentages during prints).

Of course, mileage will vary from user to printer to filament. But in my experience, with filament from a handful of major suppliers ranging from a few weeks to around a year old, as long as it's not snapping when I try to move it, it'll print fine.

Wet pla also apparently gets brittle over long periods of time which can cause issues depending on your printer setup. This is only an issue if you are storing spools open for long periods of time.