I am finally reaching out as I am at my wits end and need experienced people to help me resolve my printing issue.

I have a Voxelabs Aquila (Ender 3 v2) formerly running marlin with small but manageable annoyances like overhang and manual bed leveling and thus began my journey after a year of using Aquila to start modding/upgrading the thing.

First thing i did was upgrade the fans and shroud, this improved prints slightly but was still not satisfied.

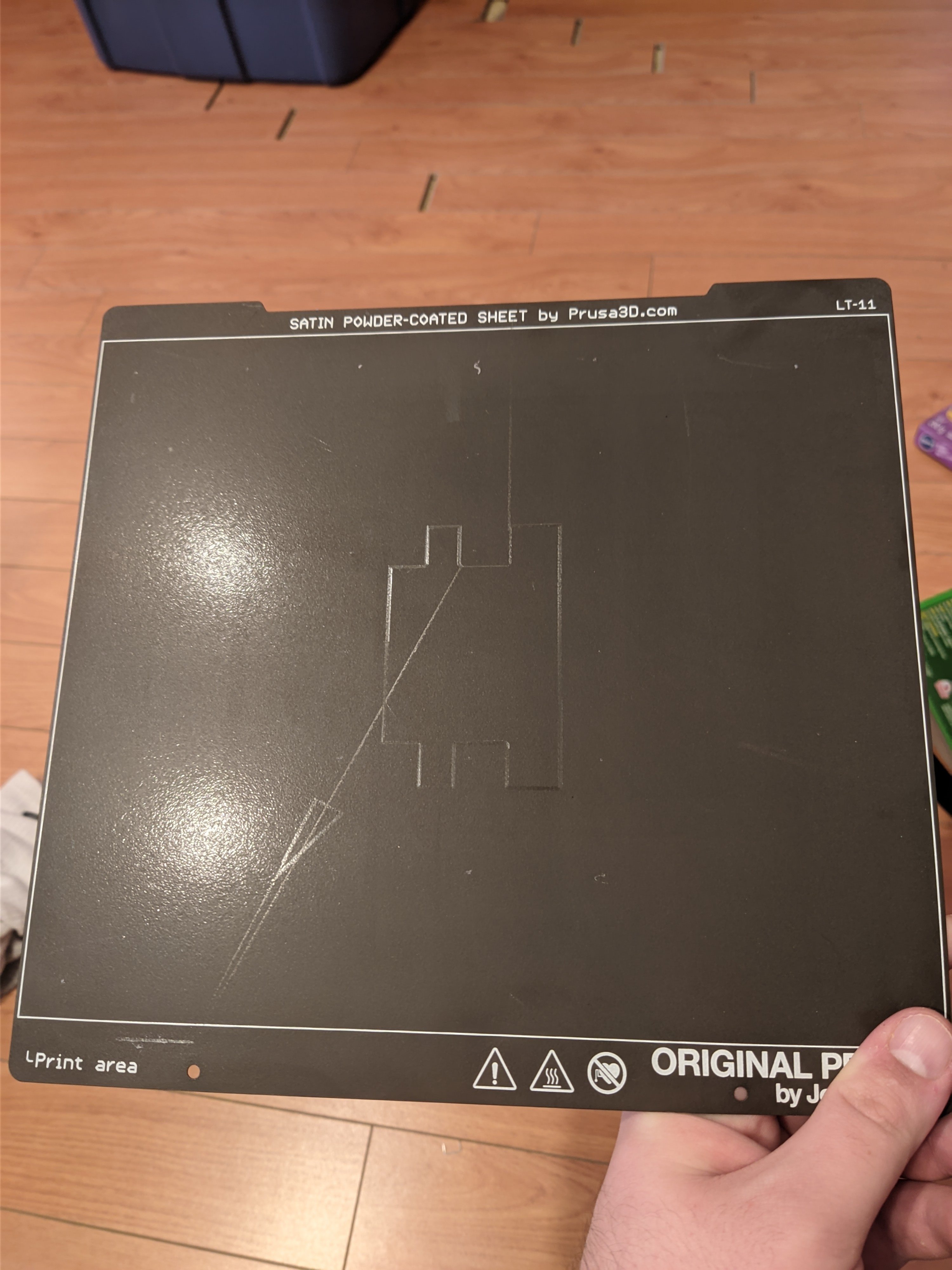

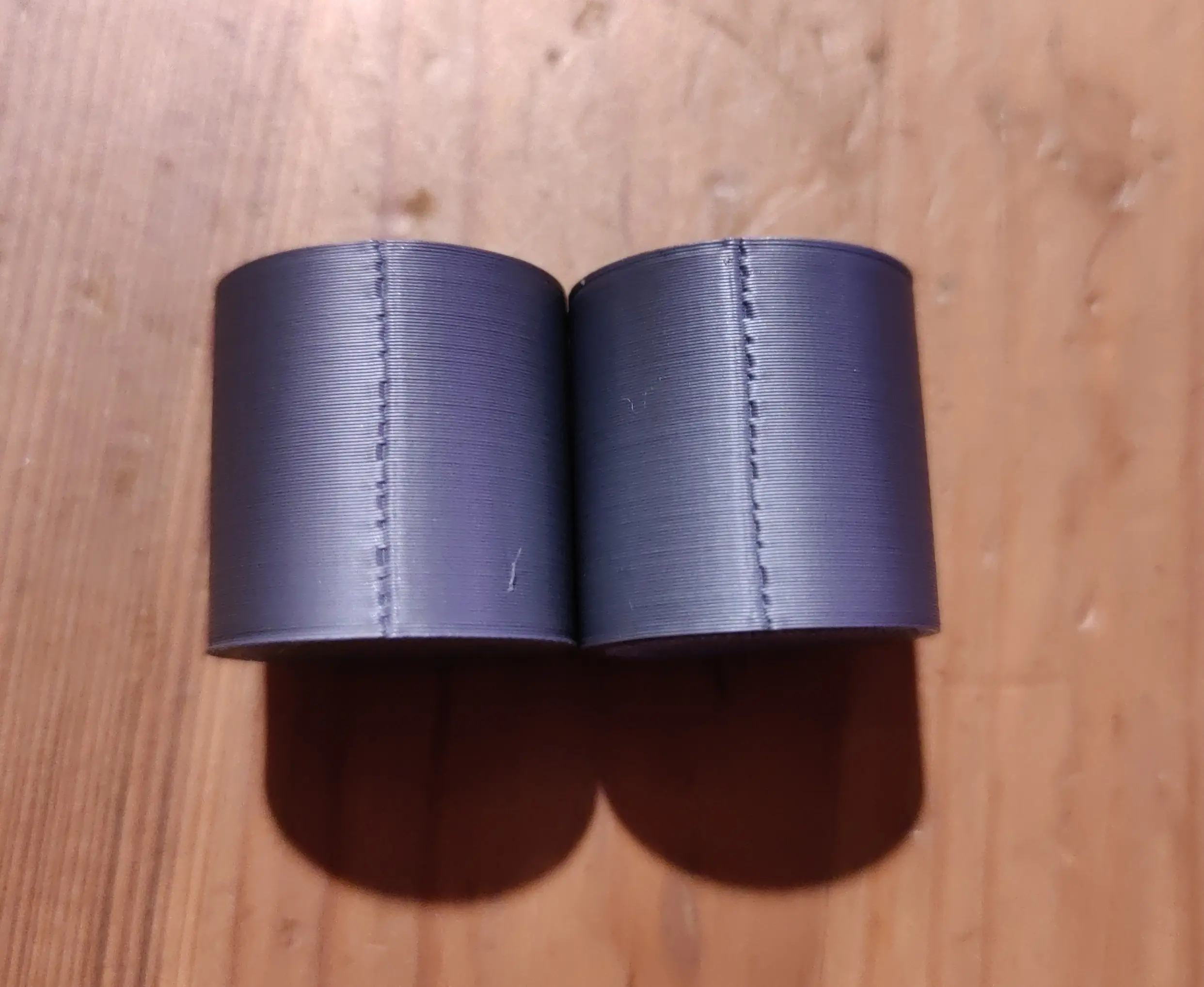

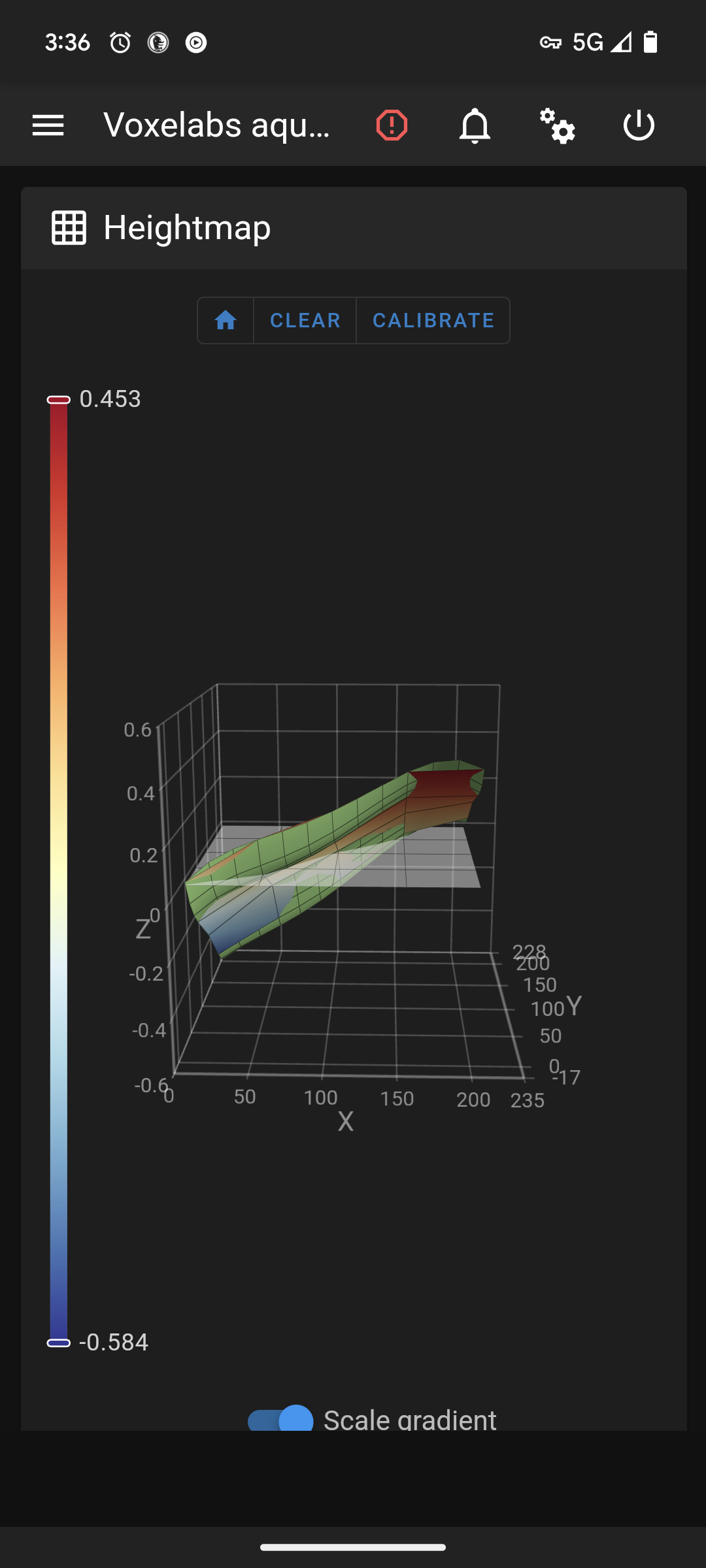

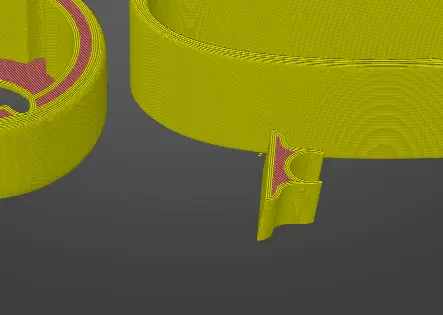

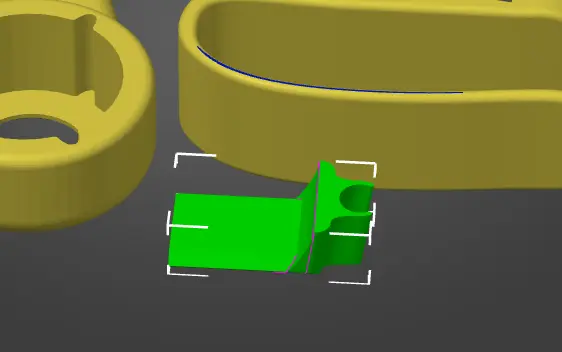

Moved to Klipper and added BLTouch and this is where all my problems started. After hours of following guides and troubleshooting of setting them both up, i still get very little bed adhesion and layers are not smooth together (gaps) with the same 3d slicing software i have been using before the switch (yes changed it to Klipper firmware in slicer)

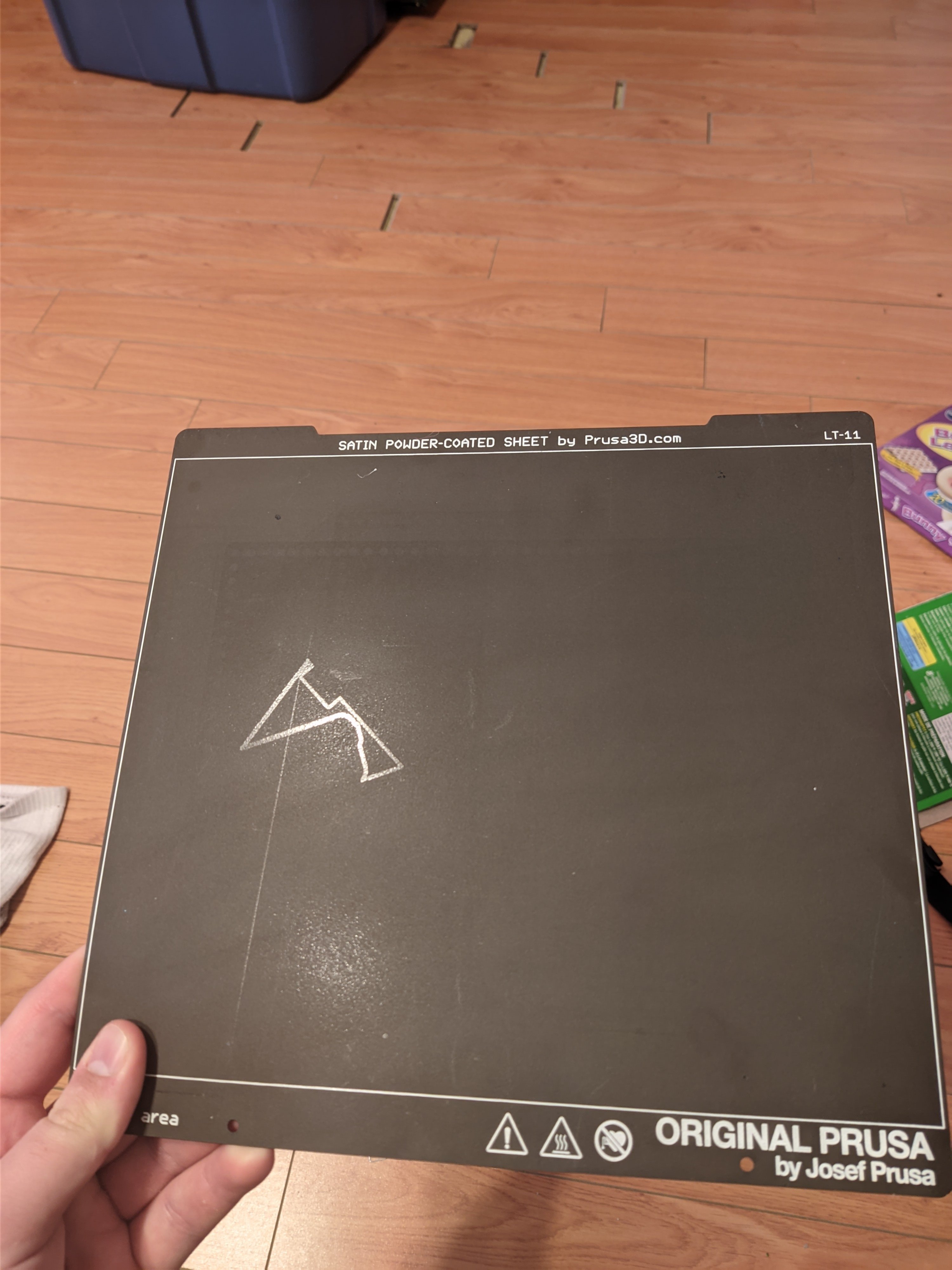

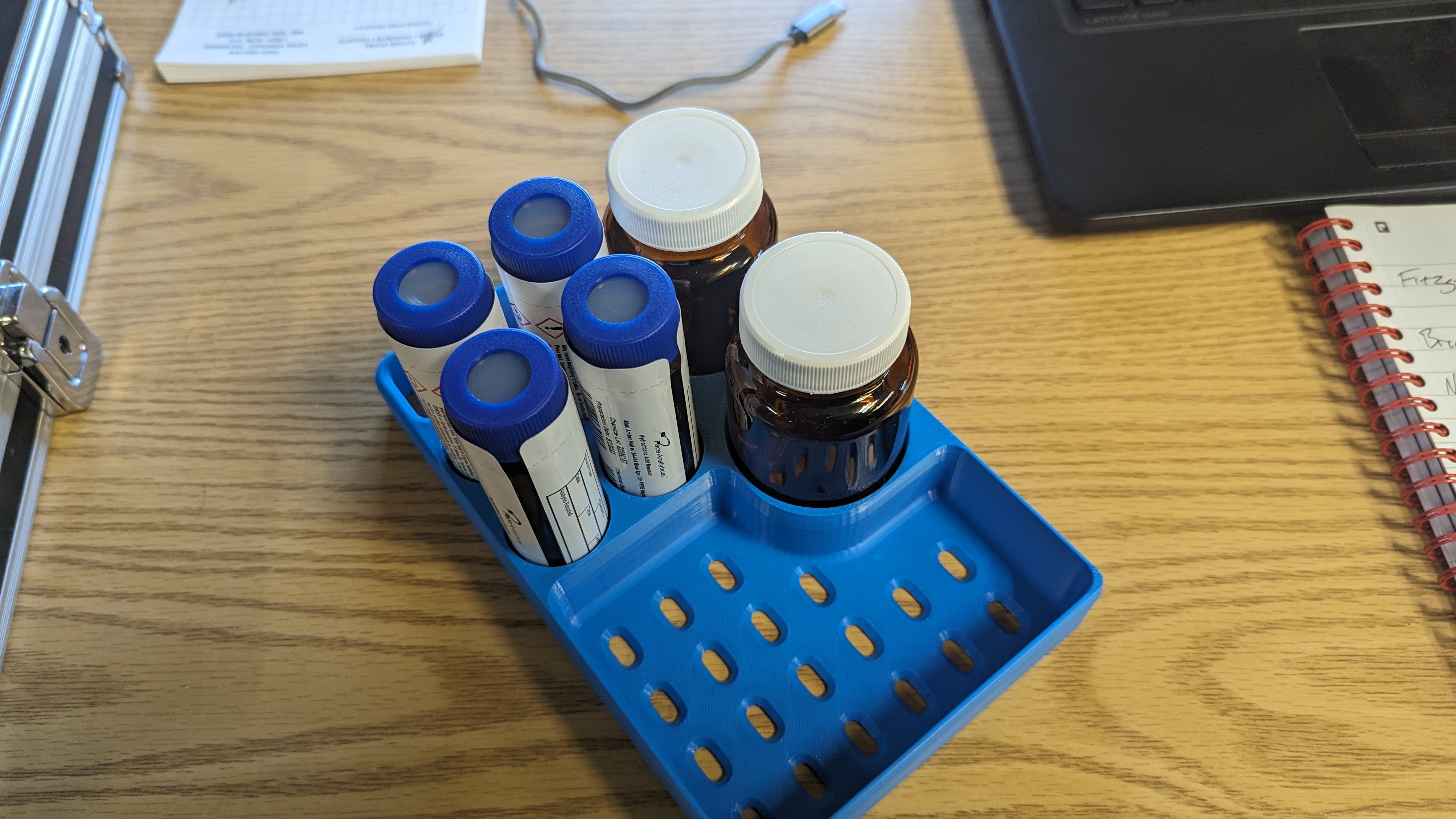

As you can see in the picture this is after a manual bed level. Where do i go from here?

Edit 2: fully cleaned nozzle, hotend, and bed without any other changes with same results.

Edit 1: forgot to add my printer.cfg

[include mainsail.cfg]

[stepper_x]

step_pin: PC2

dir_pin: PB9

enable_pin: !PC3

microsteps: 16

rotation_distance: 40

endstop_pin: ^PA5

position_endstop: 3

position_max: 235

homing_speed: 50

[stepper_y]

step_pin: PB8

dir_pin: PB7

enable_pin: !PC3

microsteps: 16

rotation_distance: 40

endstop_pin: ^PA6

position_endstop: -17

position_max: 228

position_min: -17

homing_speed: 50

[stepper_z]

step_pin: PB6

dir_pin: !PB5

enable_pin: !PC3

microsteps: 16

rotation_distance: 8

endstop_pin: probe:z_virtual_endstop

#position_endstop: 0.0

position_max: 250

position_min: -6

[extruder]

max_extrude_only_distance: 100.0

step_pin: PB4

dir_pin: PB3

enable_pin: !PC3

microsteps: 16

rotation_distance: 34.406

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PA1

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC5

#control: pid

# tuned for stock hardware with 200 degree Celsius target

#pid_Kp: 21.527

#pid_Ki: 1.063

#pid_Kd: 108.982

min_temp: 0

max_temp: 250

[bltouch]

# Can't move this configuration to include because of z-offset adjustment

sensor_pin: ^PB1

control_pin: PB0

x_offset: -28

y_offset: -15

#z_offset = 0

samples: 2

speed: 2

#pin_move_time: 0.500

#probe_with_touch_mode: False

#pin_up_reports_not_triggered: True

#pin_up_touch_mode_reports_triggered: True

#stow_on_each_sample: False

[safe_z_home]

home_xy_position: 125,125 #this should be the center of your bed

speed: 50

z_hop: 10

z_hop_speed: 5

[bed_mesh]

speed: 80

horizontal_move_z: 5

mesh_min: 3, 33 #!!min and max co-ords are based on the probes location not the nozzle!!

mesh_max: 207, 213 #needs to be calibrated for your individual printer

probe_count: 5,5 #this is the number of probing points on X then Y axis

mesh_pps: 2,2

fade_start: 1

fade_end: 10

fade_target: 0

[bed_screws]

screw1: 25, 25

screw2: 195, 25

screw3: 195, 195

screw4: 25, 195

[heater_bed]

heater_pin: PA2

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC4

#control: pid

# tuned for stock hardware with 50 degree Celsius target

#pid_Kp: 54.027

#pid_Ki: 0.770

#pid_Kd: 948.182

min_temp: 0

max_temp: 130

[fan]

pin: PA0

[mcu]

serial: /dev/serial/by-id/usb-1a86_USB_Serial-if00-port0

restart_method: command

[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 3000

max_z_velocity: 5

max_z_accel: 100

#*# <---------------------- SAVE_CONFIG ---------------------->

#*# DO NOT EDIT THIS BLOCK OR BELOW. The contents are auto-generated.

#*#

#*# [extruder]

#*# control = pid

#*# pid_kp = 31.251

#*# pid_ki = 2.510

#*# pid_kd = 97.268

#*#

#*# [heater_bed]

#*# control = pid

#*# pid_kp = 69.577

#*# pid_ki = 1.022

#*# pid_kd = 1184.541

#*#

#*# [bltouch]

#*# z_offset = 3.609