I suspect they meant ABS given ASA is also in their reply. No idea how good either material would be in this application, I just don't think it's possible to print PVC.

IMALlama

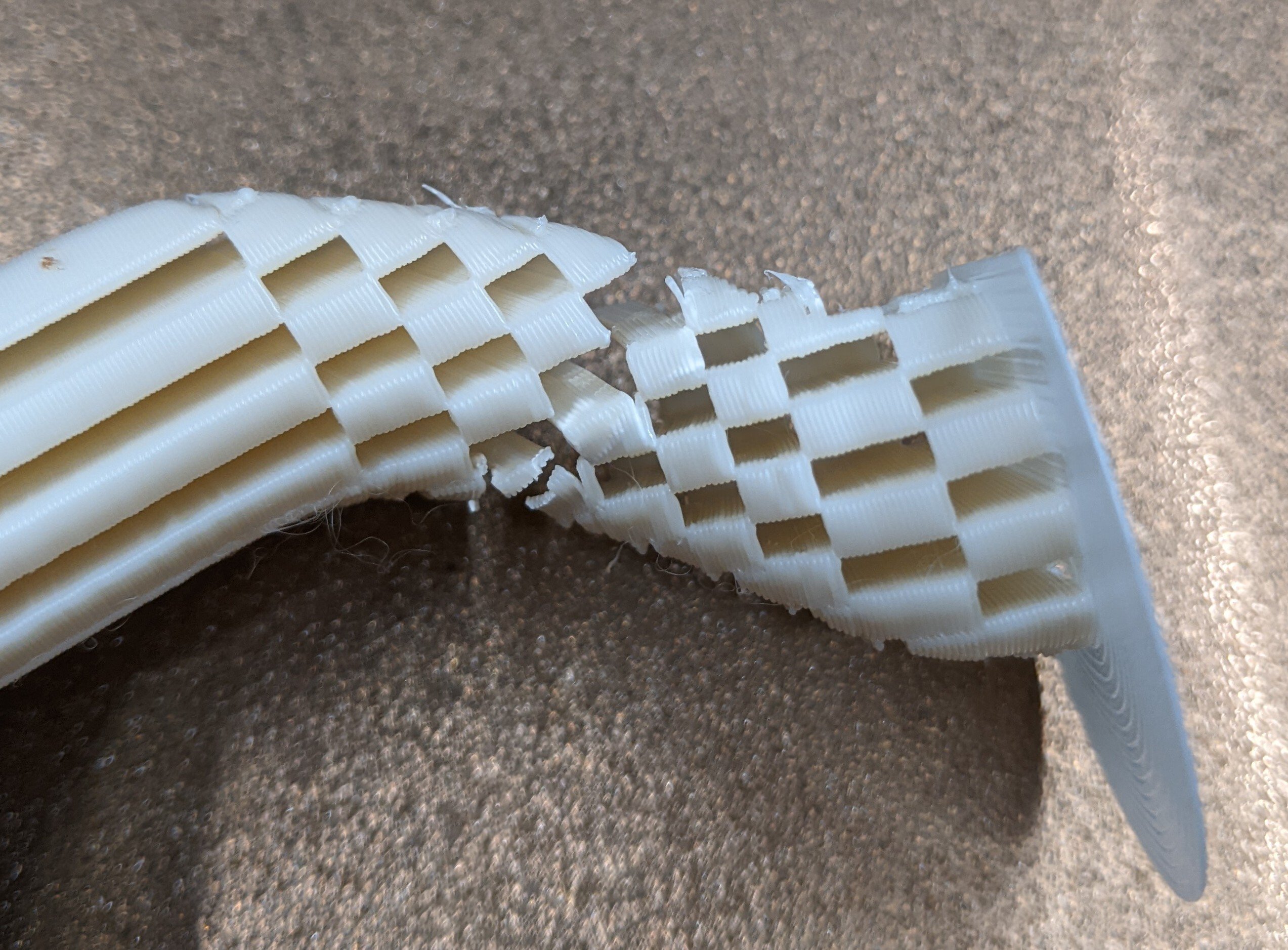

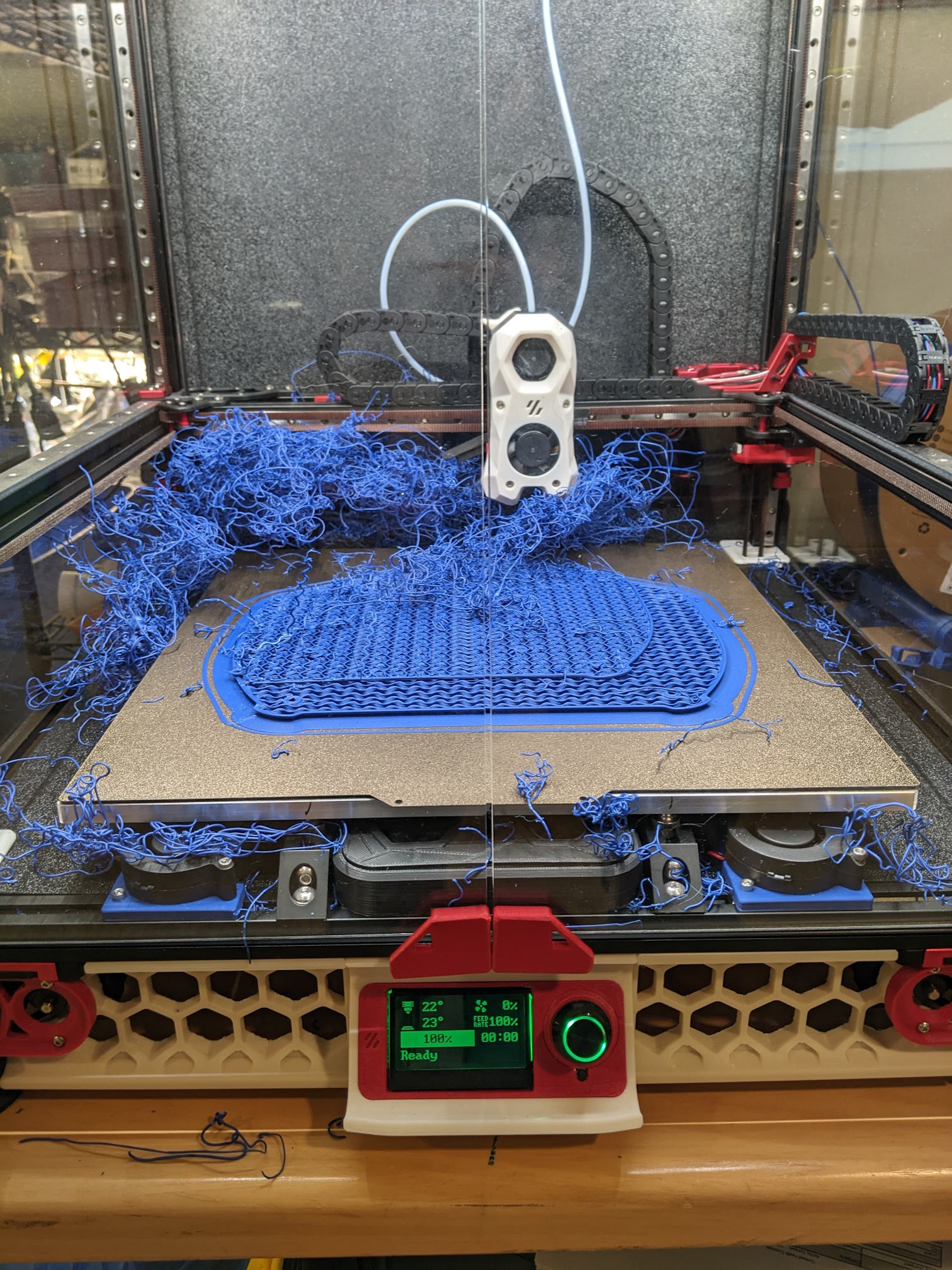

That's a lot of retractions. What is this filtering? Maybe you could print a more open structure and line it in mesh?

Also, where is this part in relation to chlorine? I can't imagine a printed part would hold up very well in high chlorine concentrations, but PETG is fairly inert...

Thanks! I'll have to stop by and pick up a spool. I would rather start with something that prints well for someon else than some random spool.

I'm guessing you mean Bambu? If so, you could print a [Nevermore](https://github.com/nevermore3d] and/or Bento box. They're both in-chamber active carbon filters and will help cut down on fumes. This is all I was running before the exhaust fan. Regarding the exhaust fan, I've found I don't need much flow - just enough to keep a slight negative pressure in the printer. I remember finding someone who ran their exhaust fan through a 3m respirator cartridge and they found that to be pretty effective when combined with an in-chamber carbon filter.

Ah, that makes sense. I live in 6a/nothern hemisphere and mine are still green. Mine are in the ground and we get a decent amount of rainfall. So far they're loving life.

Yup, if they make it through the winter then they will happily come back up year after year. I wish I had done more (read any) teaserch before putting two in the ground here. I'm going to be pushing their hardiness this winter and the plants are a bit bigger than I expected. If they do survive the winter I am considering planting a few more in a different location.

Klipper (firmware), mainsail (Web interface), obico (for failure det action) and some others. I can see why some would appreciate having a more turnkey option, but I agree with you that Klipper and mainsail make for a great pairing.

6a here. Ours are trying to grow still, but the deer keep eating them.

The USDA published an updated zone map a year or so ago. We went from 6b to 6a, which I've taken as license to be a bit more adventurous with what I leave in the ground.

We have a bed of cana lilies that still haven't been killed by this year's freeze. They usually die/get cut back to ground level and enough of them make it through the winter for the bed to reestablish.

This year I'm trying my luck with two globe artichokes.

ASA is a bit more audible than PETG, but PETG prints would also become very lose once my bed was cooled down.

I am not aware of any USB-PD power banks that take AA's. The idea behind my comment was "you don't have to worry too much about availability of OE batteries".

If heavy duty means "lets you carry more weight in your bed and tow more" do not do it unless you actually have weight in your bed or tow a lot. To do this, the springs have a higher spring rate which makes the ride very hard unless you're loaded.

DSLRs all have optical viewfinders, since the SLR bit basically means "uses a mirror and a pentaprism for the viewfinder".

Most digital interchangeable lens digital that I know of use proprietary form factor lithium batteries. Lithium is a lot more energy dense than an alkaline battery and are rechargeable. They also offer much more stable voltage as the battery discharges, which probably makes them more attractive to camera OEMs.

Why shy away from lithium packs? Even for my ancient D40 I can still get new, but aftermarket, batteries.

Most newer cameras can charge the battery in the body without removing it. Some even support USB-PD and can be externally powered indefinitely.

In fairness, they never said a 2.4.