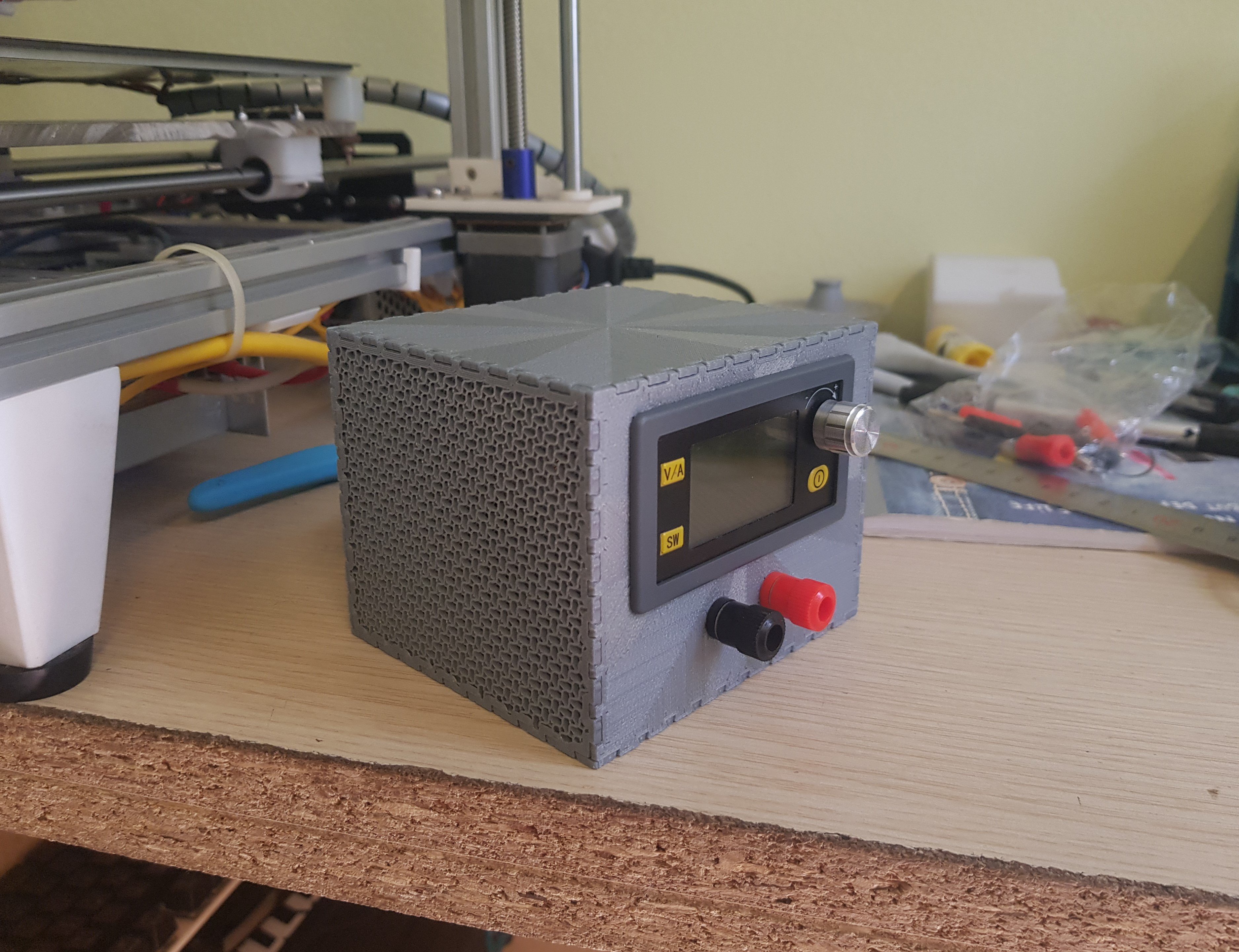

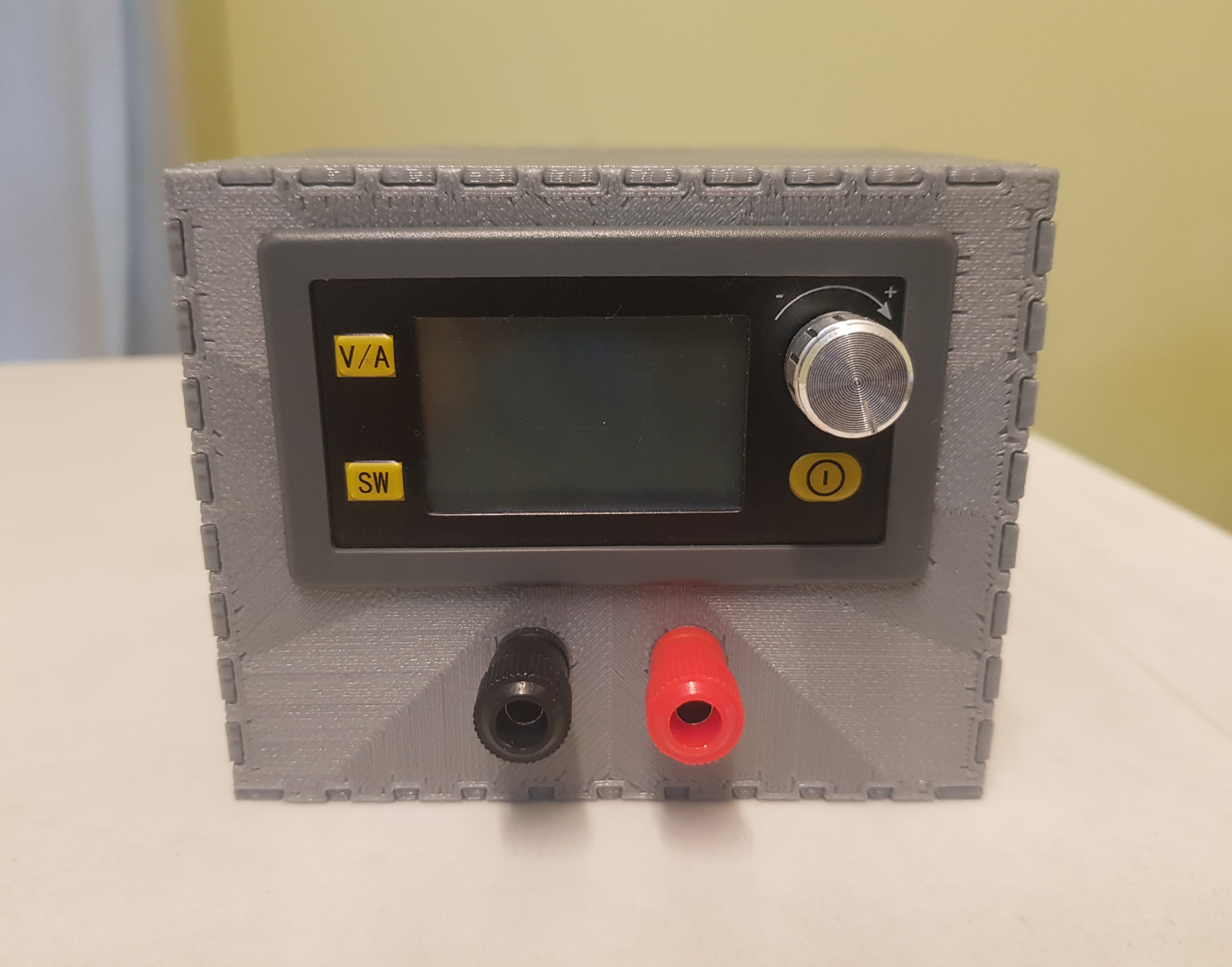

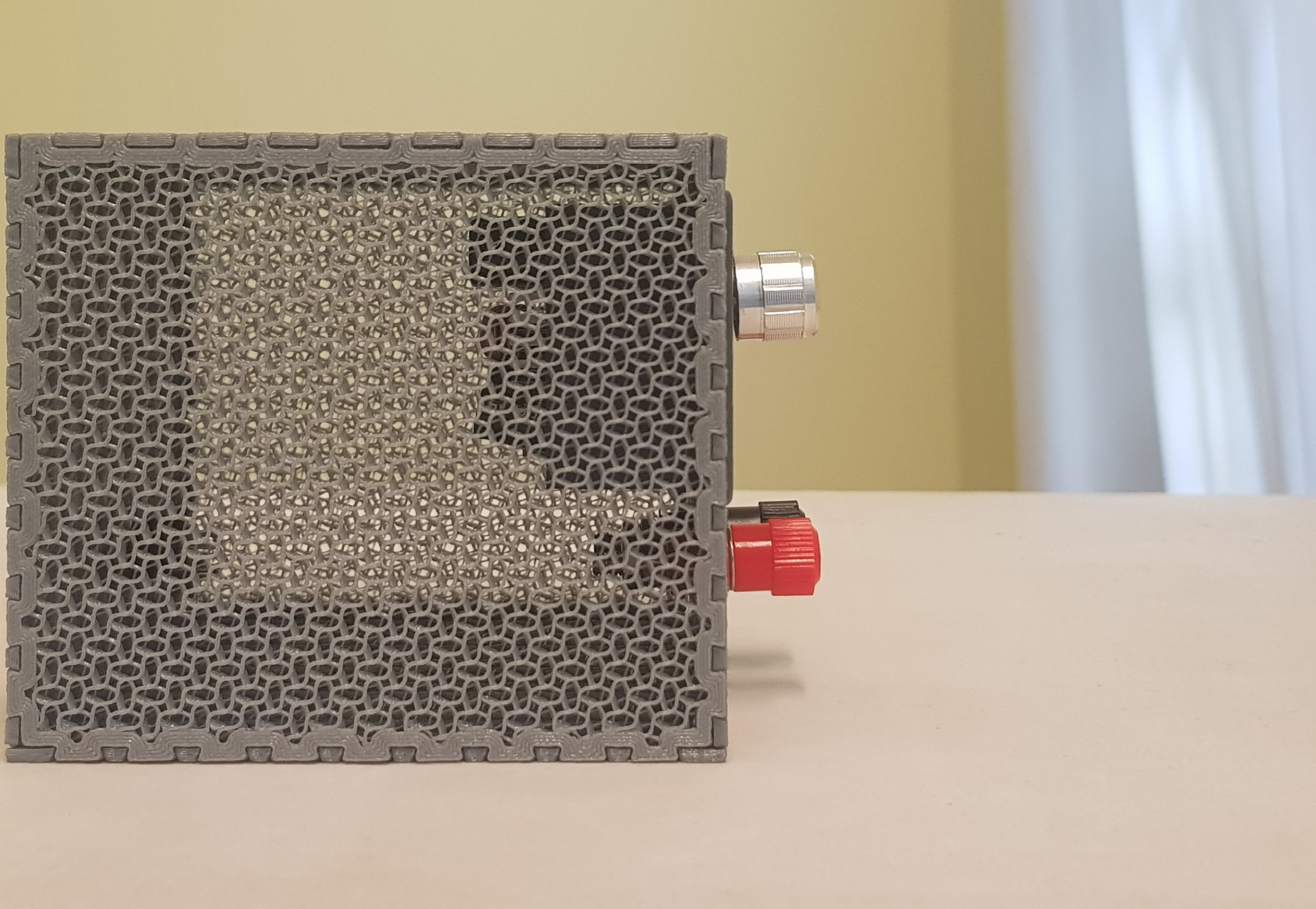

It is held together completely by the joint. These dovetail joint are known to be very strong reliable.

x7tYnC6c

My phone can't capture it very well. The size of the dovetails depend on the plate thickness, so they're quite small. Here's what they looked like in CAD.

The interface module which do everything is just the cheapest one I found locally. It called a buck boost module but that doesn't really narrow it down. Other than that it's just 2 binding posts and whatever supply you want. I used a barrel jack plug to reuse my old laptop charger.

That's the neat thing! If passive convection can't do the job, I just have to print a new top plate with fan mount.

Not everyone cup-of-tea, but build123d/cadquery is pretty good if you like programming. I used it to make some dovetails joint which would be annoying to do with gui cad.

This is only a prototype, you can see there are no wiring inside. The artifacts are because I print at 150m/s and 5k acceleration, on a bed slinger.

While these changes will eventually happen, as all of these companies are meant to make a profit from the start. The reason they're all happening now is because of the coming recession, or at least the believe that it will come.

I tried .8 nozzle for a while, but my vanilla hot end just can't keep up at higher speed.

Yes. I'm certain it is a build quality problem. The probe is just plastic and by design hang freely. Even a steel rod with bearing can easily be deflected by a few tens of micron.

I meant the probe is deflected by the texture. Taking multiple sample is what I'm doing, yes. It take at least 5 samples for it to be reasonably smooth, which is why I'm asking other experience.

Nah it rock solid. The variance come from the texture itself.

Yes.