The first time actually watching hololive content and boy was it entertaining!

Monogatari series. I must have watched that entire series like a dozen times already. I absolutely love the VA's performance. Finally reading through the Light Novels now.

Hajime No Ippo. Manga is still a blast and the anime was incredible too.

I had a good time with Blue Lock as well.

Sigh... I just bought a usb-c cable that doesn't support display stream compression but is fine for 160w power. No where did it ever say it wasn't capable of driving multiple monitors...

Here's the issue I have with your position... AI is such a generic term it's difficult to have a fulfilling conversation using it but in my field a form of AI like machine learning is going to eliminate an entire sector of manufacturing... Boutique precision machined components have been thought as an impenetrable wall against AI but it's basically the same lackluster defense used not long ago about Generative images couldn't produce hands properly... It's not a matter of if but when.

Imo, the catastrophe happens when a successful AI scales. Or perhaps rather how suddenly a successful AI model will bury the existing system into irrelevancy. Boeing and most aerospace manufacturers have a machinist union but none of that will protect against a future where people are no longer necessary.

I don't think it's wrong to have AI eliminate jobs but it shouldn't come without warning. I think it's rather forward looking to be monitoring ongoing AI projects and establish contingencies for folks who will become displaced by it's rapid spread.

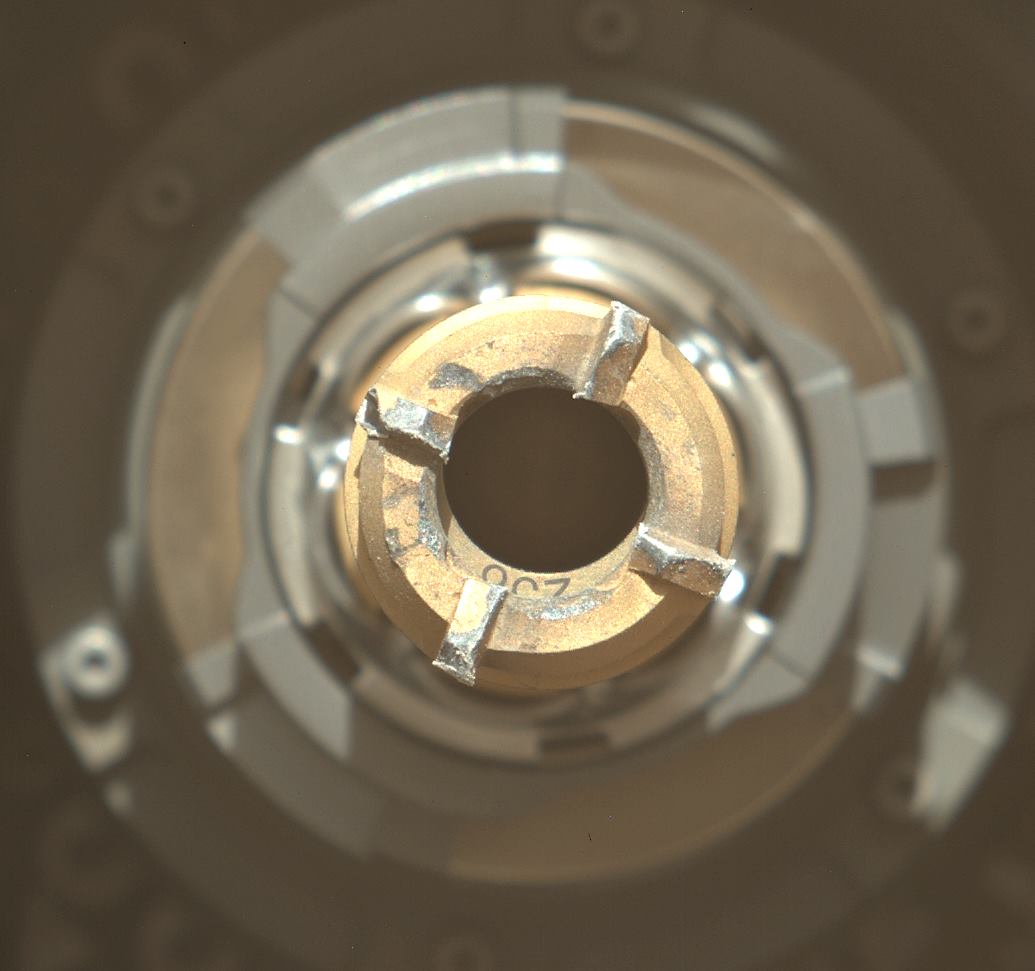

Trying to get capto systems for the multi-task lathes and zero-point pallets for the mills. I do prototyping and it's the only way to stay sane.

If your power consumption is actually 250 then go for a 500w PSU. You'll get better efficiency.

Anandtech (rip) used to be my go-to for PSU efficiency curves.

Ah a Joe Pie classic. If you've seen his videos, you know.

Death stranding directors cut. I'm 10 hours in and having wayyy to much fun with the gameplay loop. Still on chapter 2.

Maybe for the generic cat/dog image sharing boards but niche topics like machining are still thriving.

3am... Need to be up in 4hrs...

Imma need me some 4 fairy soup.

I’m pretty sure they would have to upload millions of pictures of their own creation first.

From the YouTube guides in generating your own Lora models... Naa just a couple reference poses and it's ready to go.

Hachikuji Mayoi from monogatari series.

Senjougahara Hitagi from monogatari series.

Deishuu Kaik-- oops you didn't read that.