I’m curious how much you paid for it, SLS can be pretty expensive! Very cool.

Clacksmith

A place for all things about dice making. Ask questions, get advice, show off your creations!

$8USD each for d6 and smaller, up to $9USD for a d20.

Damn, that’s not bad at all. I had a plastic part the size of my fist sintered (same technology) a few years back and it costed about $450

Looks really cool! How does it feel tactilely?

Also, you should repost this to [email protected] :)

Once polished, they feel very nice. I chamfered the edges so they don't poke my hands.

Are they solid metal? How heavy do they feel?

Solid metal, similar to my Norse Forge metal dice.

Link to the printer?

Jlcpcb.com

I didn't expect that a company like that would accept a one-off order that costs as little as you say the dice cost. (I assume you spent several hundred dollars at most.) I just figured that anyone who says "aerospace" wouldn't bother doing business with me, but I guess I was wrong.

How receptive were they when you contacted them?

Online ordering form. All I had to do is upload the STLs, choose a material, and submit. They send an email in a few days to say that everything is ready or bring up any issues they find. You pay then.

I'm pretty sure that small builds are fit into the schedule when they can.

They're crazy cheap and good for PCBs, which is their main thing. The first order is basically just the cost of shipping, but not Mich more after that.

I run off my prototypes on my PCB mill to test them, but only because I'd have to wait 5 days for a good one.

Do you know what sort of sintering technology they used? I got to order custom parts laser sintered from tungsten at a job I had, which was pretty cool.

I don't. The last time i was close to parts manufacturing, I was drafting parts on vellum.

Sometimes lower cost meal 3d printing can be done with normal fdm machines with a very high metal content filament, then sintered together and the binding vaporized out in an oven after the fact. I don't know if that was the process used here though, or if this was SLM.

The blue dice look like you could chew them and they'd taste of Listerine :P

Forbidden jolly ranchers.

whoa, that's metal (literally)

What kind of polishing did they need?

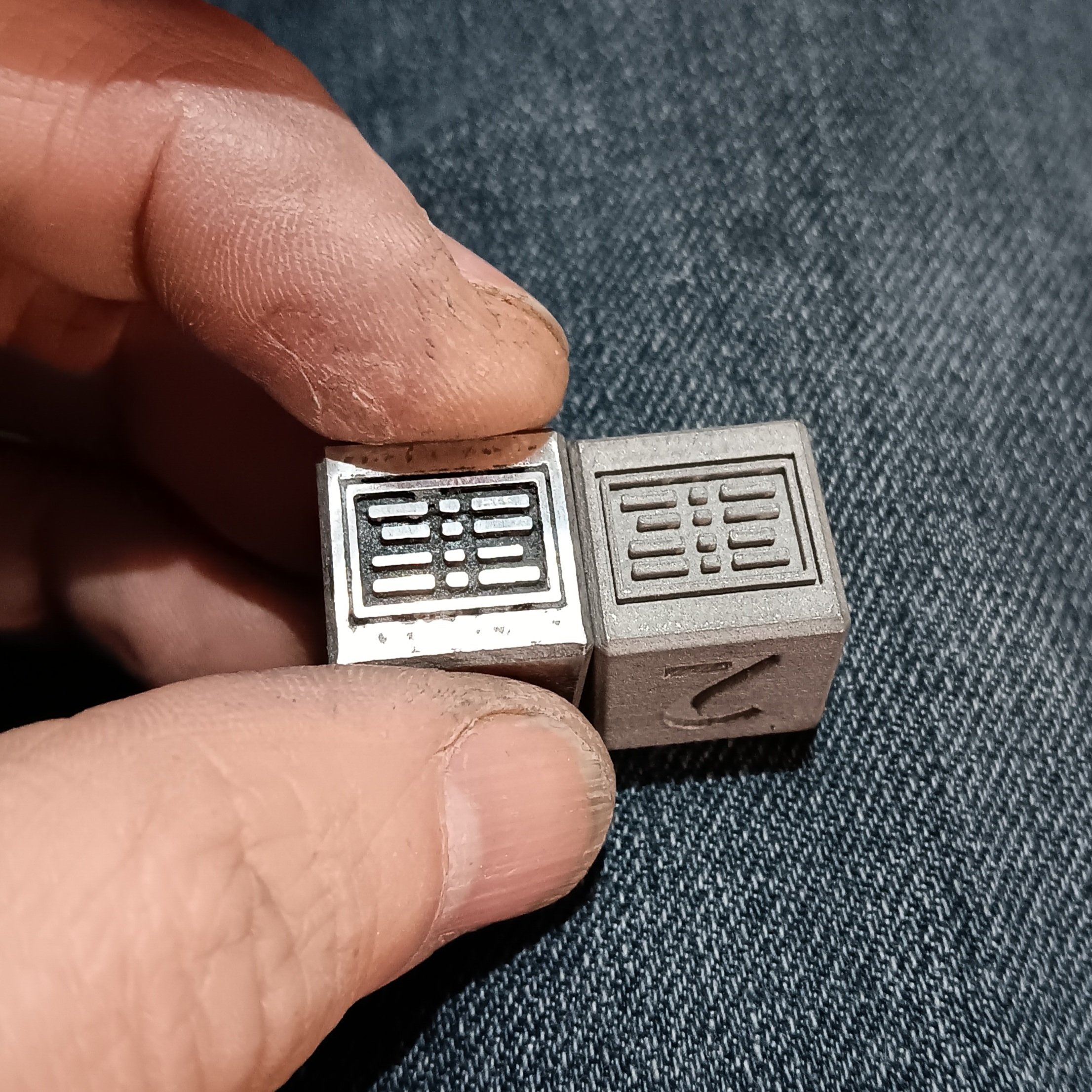

So an earlier, rough polish is on the left and the original finish on the right.

So an earlier, rough polish is on the left and the original finish on the right.

I started with 400grit, then went P600, P1000 and finished with a stainless steel polish and ball polisher on a drill.