3D Printing

4527 readers

43 users here now

For everyhting 3D printing related.

Please be excellent to each other :)

Icon by Freepik, Banner photo by Thiago Medeiros Araujo

founded 4 years ago

MODERATORS

1

2

4

5

6

19

[BambuLab Blog] - Firmware Update Introducing New Authorization Control System

(blog.bambulab.com)

7

8

9

10

11

68

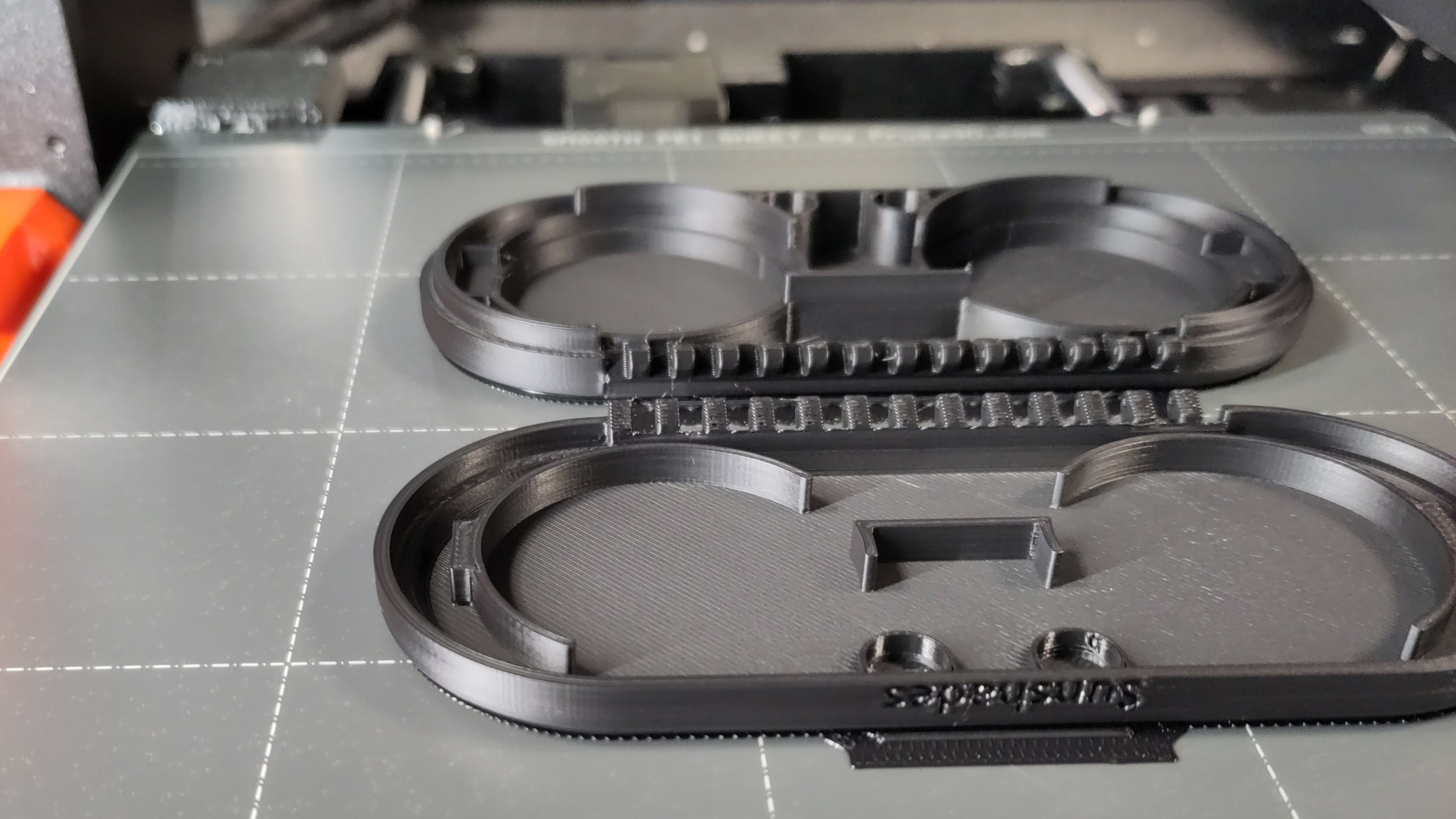

I finally found cheap donor sunglasses for my 3D-printed clip-on shades

(raw.githubusercontent.com)

12

13

14

15

16

17

18

31

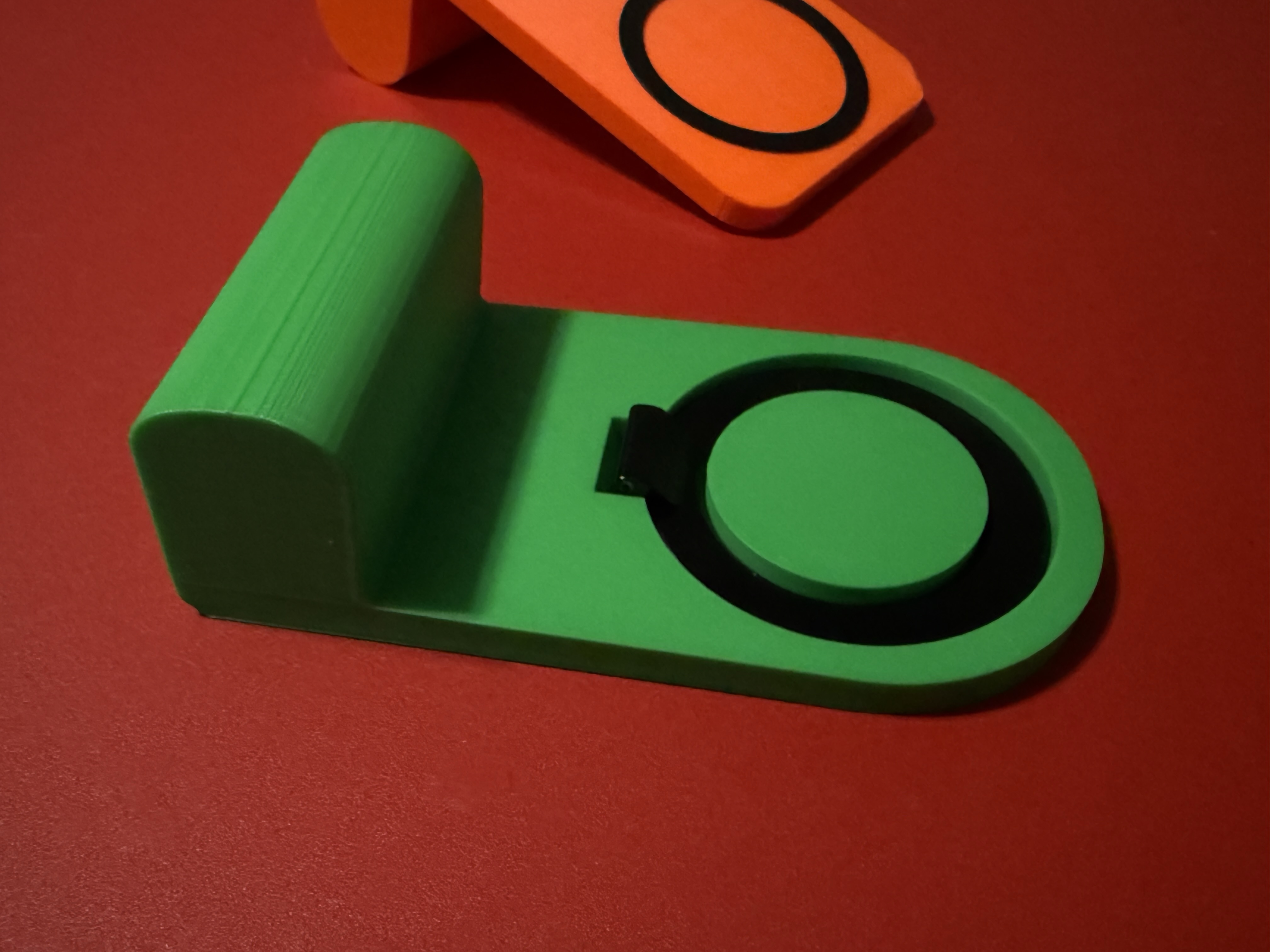

Designed this coaster, because I wanted something tidy looking and dual color, without filament changes

(media.printables.com)

19

20

21

22

23

24

25

view more: next ›