I love the YT channel Project Farm. It's unbiased, well thought out, practical, and numbers-focused (as much as a video can have without getting boring) approach is refreshing. Not every test is perfect, not every sample size appropriate, but this is a mechanical guy that knows his shit and is as curious about the results as the audience.

His latest video compared a bunch of ratchets from different manufacturers... plus a 3D printed one. Made of carbon fiber nylon and printed with a newly purchased BambuLabs X1 Carbon, it failed miserably.

The problem?

I'd assume it was print orientation. It's printed on its back, with the socket connector pointing up, meaning layer lines are parallel to the force.

But, then I did a little digging...

Here's the presumed model. It's 100% print-in-place. I assumed the instructions would make mention of the correct orientation. They don't. Uh oh, am I the wrong one? Nah, probably just a random, low quality model, right?

Oh, it has a decent number of makes that were presumably done in the default orientation, but maybe... oh, okay I'm deeeeefinitely wrong.

This is the first time an object has been designed on Earth and then transmitted to space for manufacture.

I assume it's oriented for printing without much fiddling. Looking at the Thingiverse comments, there are people have success with PLA.

Maybe the temperature was too low to get good layer adhesion. Is CF Nylon brittle? Could leaving the filament out a few days, being so hygroscopic, lead to this?

So, any other ideas out there? Should he have used a different material?

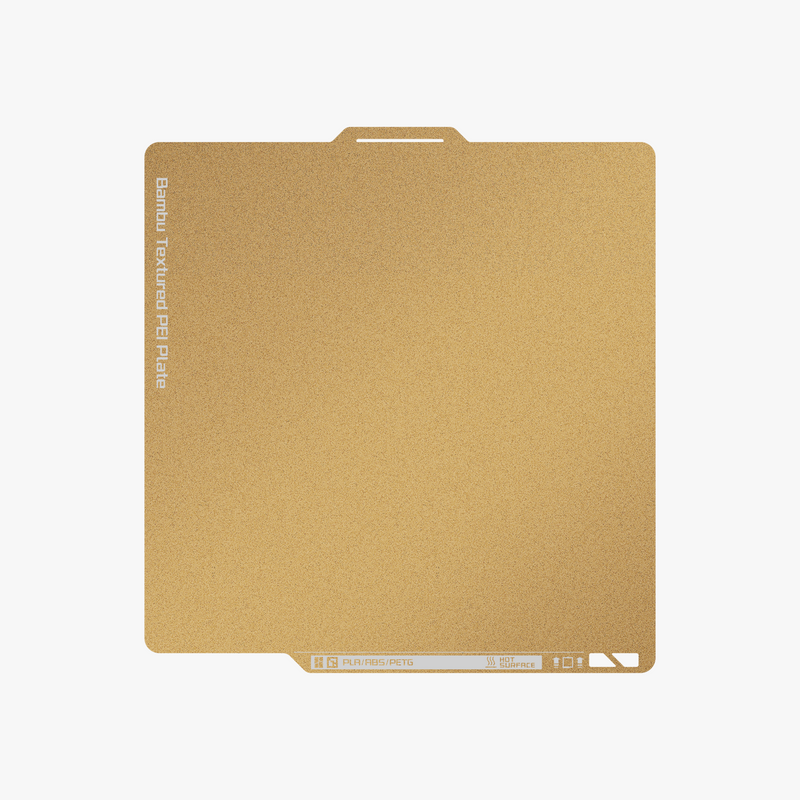

(Also, it's worth mentioning that he specifically says he bought the printer just for this test, so I'm not sure how much experience he has with 3D printing. That's wild to say because if you hear someone say they printed carbon fiber nylon, you assume they have significant experience. But, as an X1C owner myself, that's a totally realistic possibility.)

I forgot 13th Warrior!