Soldering

This community is for electronic hobbyists to discuss projects and is focused on soldering. Everyone is welcome from the noob to people who have been soldering as a hobby for decades to people who solder professionally. We'll talk about materials and techniques, equipment, and projects. Everyone is welcome. All questions are welcome. Post photos and ask for help.

RULES:

-

All Lemmy.ca rules apply here.

-

Everyone (see rule 98) is welcome.

-

If you’ve seen a question 100 times answer it the 101st time or ignore it. Even better, write a complete, detailed answer and suggest that the mod(s) pin it to the community.

[Did you actually think there were 98 rules?]

-

If you present something as fact and are asked to provide proof or a source provide proof or a source. Proof must be from a reliable source. If you fail to provide proof or a source your post or comment may be removed.

-

Don’t be a dick. Yes, this is a catch-all rule.

-

The mod(s) have the final say.

view the rest of the comments

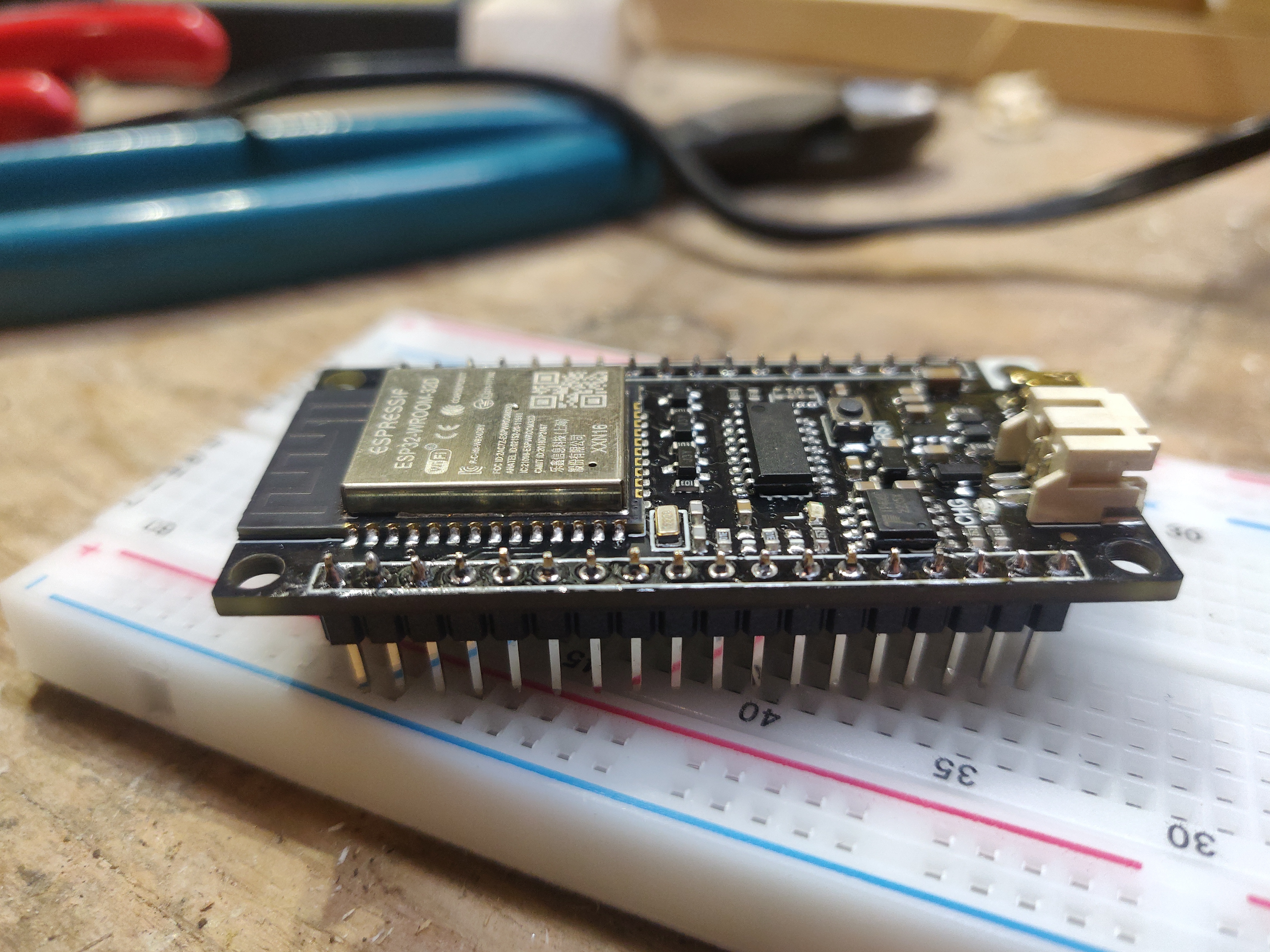

Hi. Sorry I'm late to the party. I've made a video that I think will be helpful. I'm going to post it as soon as I can get it edited.

Couple of tips. Buy liquid flux (someone has already said this, I think.) Flood the area with liquid flux. The liquid flux helps your solder to flow and it gives you a nice, shiny surface. Have you ever tried to reheat solder and found it very uncooperative forming point and ugly joints? Liquid flux fixes that. Apply heat to the pin and the pad and apply solder to the pin and the pad, not the soldering iron. You need a bit of solder on the iron to form a thermal bridge but you definitely want to apply the solder to the pin and the pad. That way the solder will only melt when the pin and pad are hot enough for the solder to clow properly. You want a nice fillet between the pad and the pin. You don't want a blob but you want the pad covered and the solder to curve up the pin.

Definitely tinned the top beforehand, although I was finding the tip had cold spots, so probably need to change the top. I will definitely check out that vid when I get home. Thanks so much!