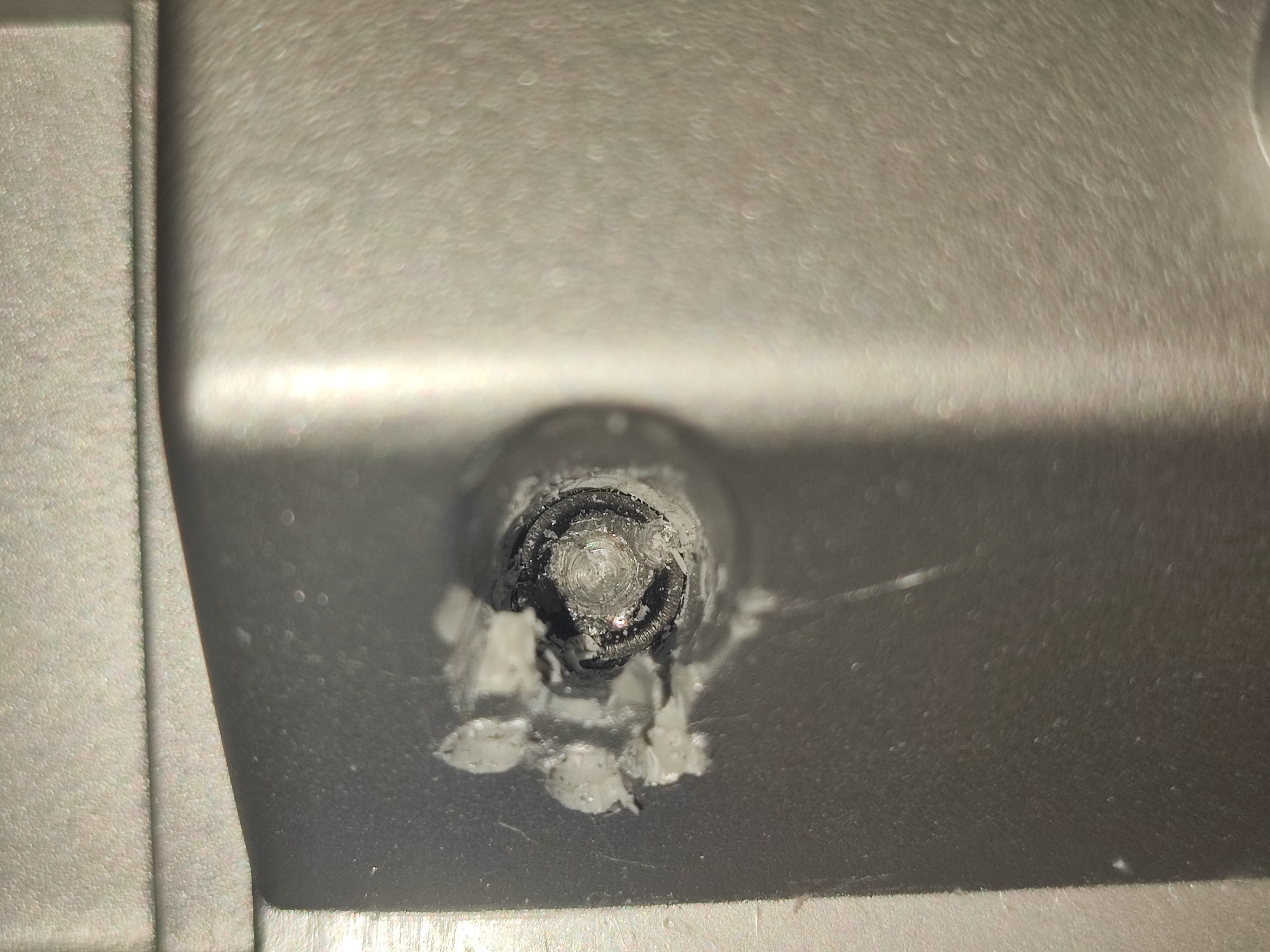

Hope I have interpreted the photo correctly and this is just a metal screw, that has become to round to be screwed out with a hex wrench.

In such case, I use a drilling machine to carefully drill a small metal-suited drill a few millimeters into the screw. Then I remove the drilling machine and hold the drill (still in the screw) with combination pliers (or similar pliers) and unscrew the metal screw (again carefully).

I hope my translation of the tool names are close enough to understand what I mean :)

In German it would be: Einen Metallbohrer mit Bohrmaschine einige mm in die Schraube bohren, dann mit Kombizange den Bohrer festhalten und zusammen mir Schraube herausdrehen.

EDIT: also please be careful when opening up the keyboard and document your steps with photos. When I repaired a 80s Korg some years ago, there where many parts that could spring out of place, e.g. when lifting the keys.

Top:

Top: