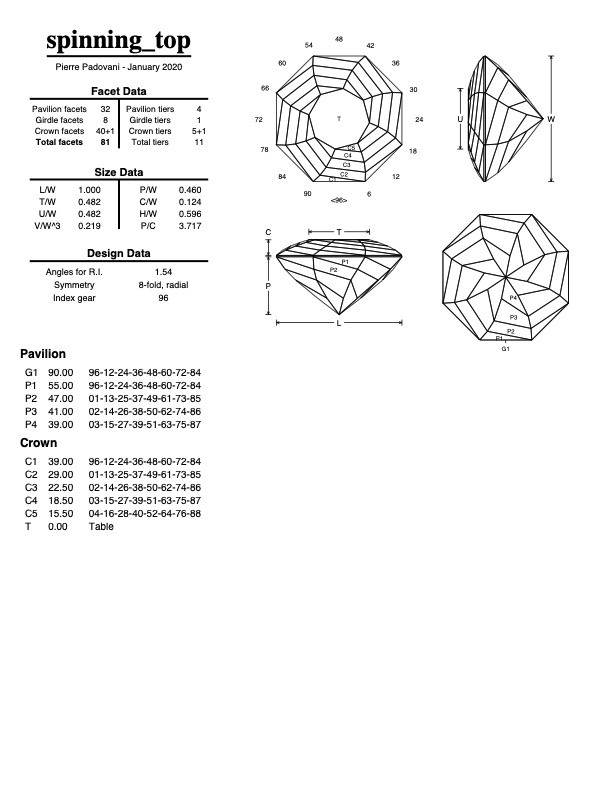

Now it's time to finish cutting the remaining tiers in the pavilion. Here is the diagram I'm cutting:

First thing I'm going to do is switch my lap to 1200 grit and recut the existing girdle and first tier facets. I'm doing this because the 1200 is more accurate and I want to get the cuts close to their final depths.

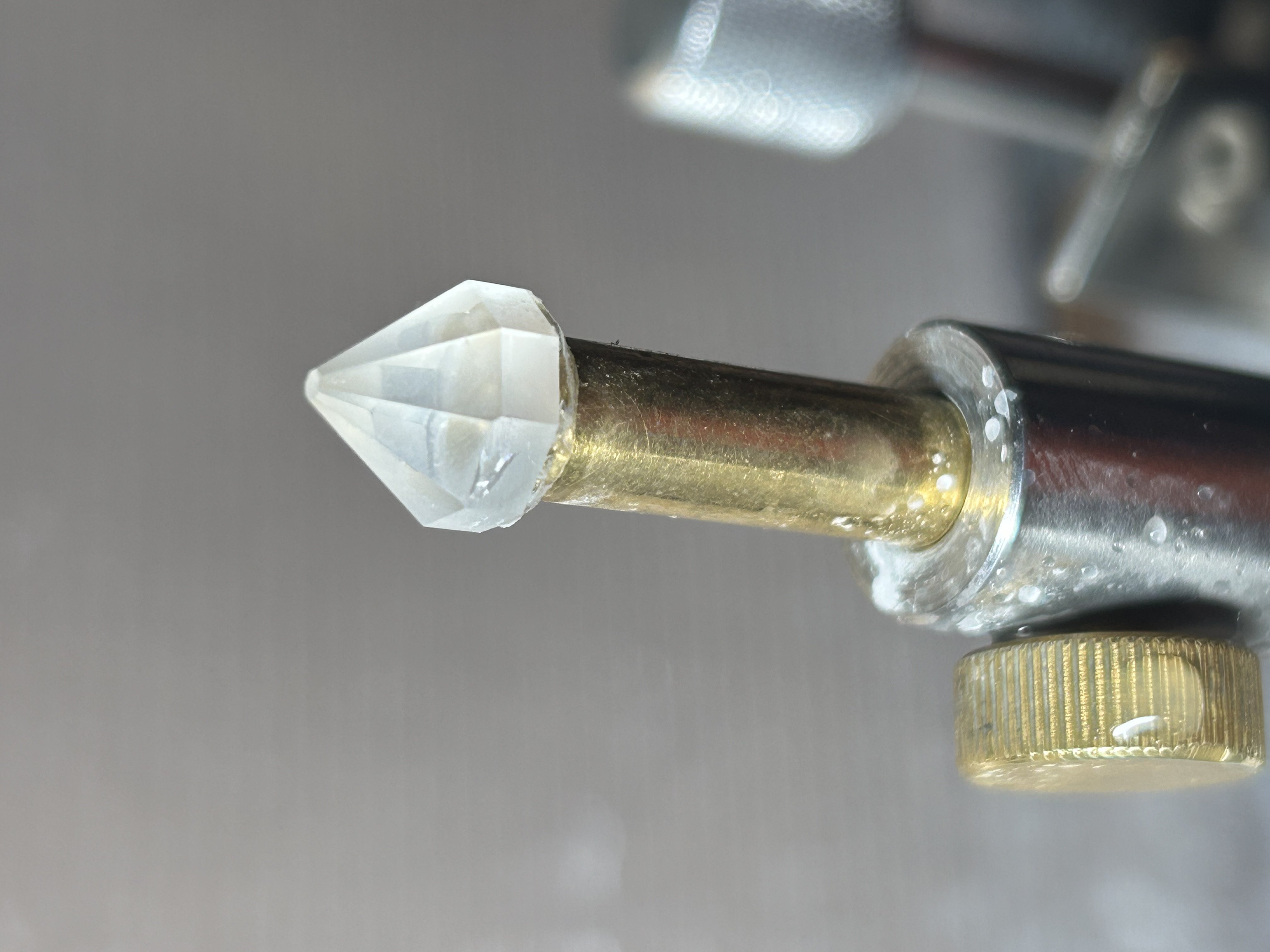

This is the result, can you see the issue?

There is a fracture in the stone right around where the girdle and facet meet, the shiny spot. The issue with this is two fold:

- The stone will have a visible imperfection when finished

- This is a weakness that may chip off the stone in the future.

So, I need to cut that out. What I need to do is reset to 90 degrees and cut that facet's depth down until the imperfection is removed.

While I was doing this I heard a crack sound, pulled up the stone and saw that the fracture had broken, and now I have a divot in the stone where it used to be.

So, keep cutting until it's gone

You can see in the above picture that the divot is gone, and the girdle facet is larger than its neighbors. Time to finish cutting the remaining girdle facets to match, and recut the second tier.

Before:

After:

Now I set my angle to 47 degrees and cut the next tier:

The first of the defined triangular facets appear. Something to note, when cutting we try and make the meet points as perfect as we can. A meet point is where the tips of the triangles meet. In this case the tip of the triangle meets the joining point of two girdle facets.

Onward to 41 degrees and the next tier.

So, even though the first second tier is now triangles, the third is going to end up being parallelograms.

Last tier using 39 degrees.

Ok... so I made a mistake here. I outlined the facets with an aluminum pencil to make it easier to see the issue. I didn't realize that this last tier was going to cut as fast as it did, and I over cut the first facet of the tier.

Good news: I can go back to the second tier at 55 degrees and recut those facets, then iterate back through the other tiers.

Bad news: I have to recut all of those facets again.

Next time I'll have the pavilion cut and polished and ready for transfer.