Lets look at the design again:

I always start on the pavilion tiers, and the first step is to cut in the girdle. When I roughed the stone into a cylinder it wasn't going to be perfect, so what I do is set my angle to 90 degrees and iterate through each index (96, 12, 24, 36, 48, 60, 72, 84) until I find the one index that is the deepest. That is if I set the stone at index 96 and increase the depth such that the angle hits 90.02, and the next index reverts to 90, I'll increase the depth until the angle reads 90.02. This finds the location on the stone that needs the least cut off, and is the starting point for cutting in the girdle.

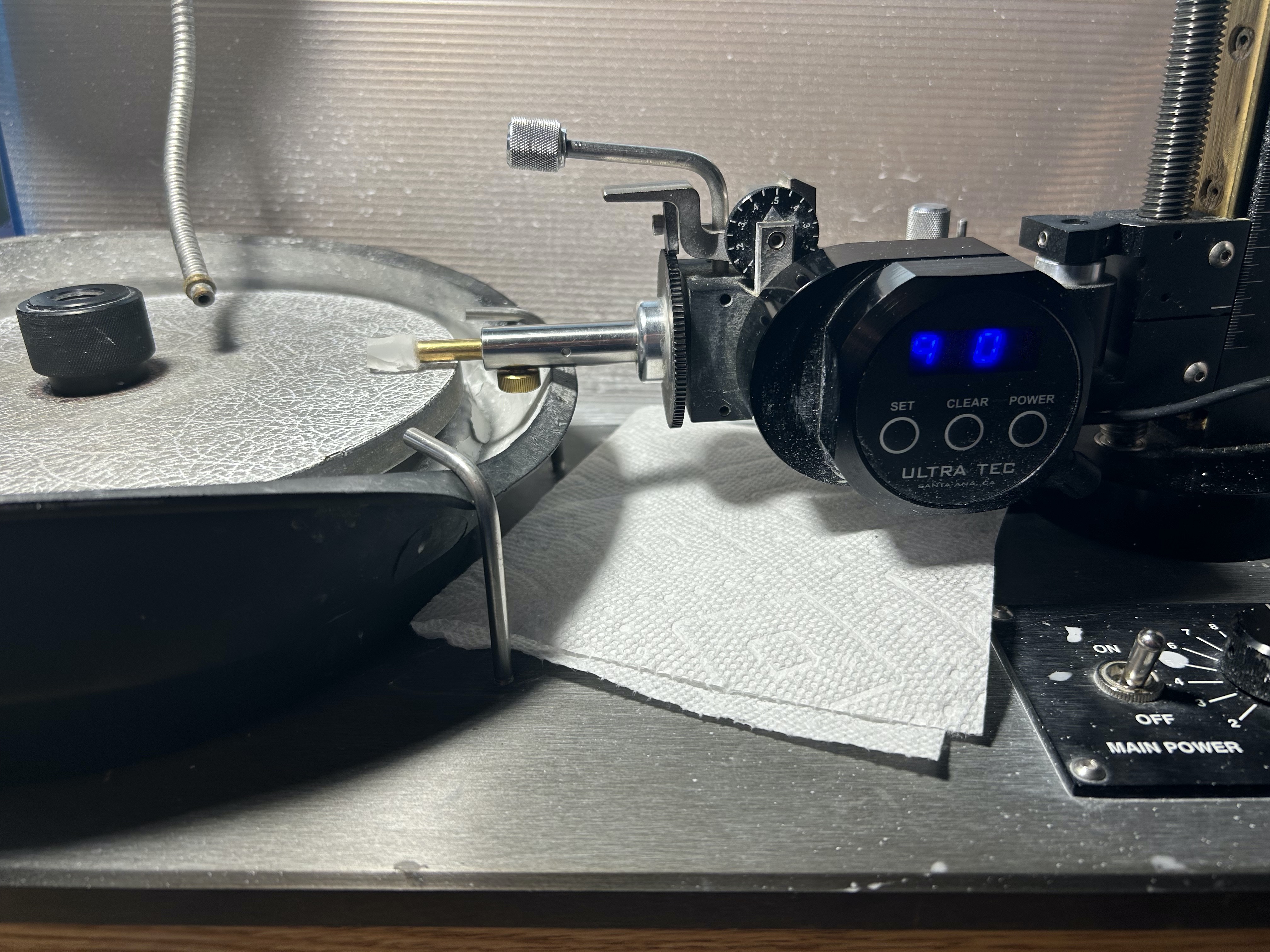

To cut the girdle I'll increase the depth to something like 90.20 and cut until I reach 90.00 again. If the facet looks like it is even and takes up enough space of the circumference then I'll move to the next index and leave the depth alone. Once I've cut the girdle in it looks like this:

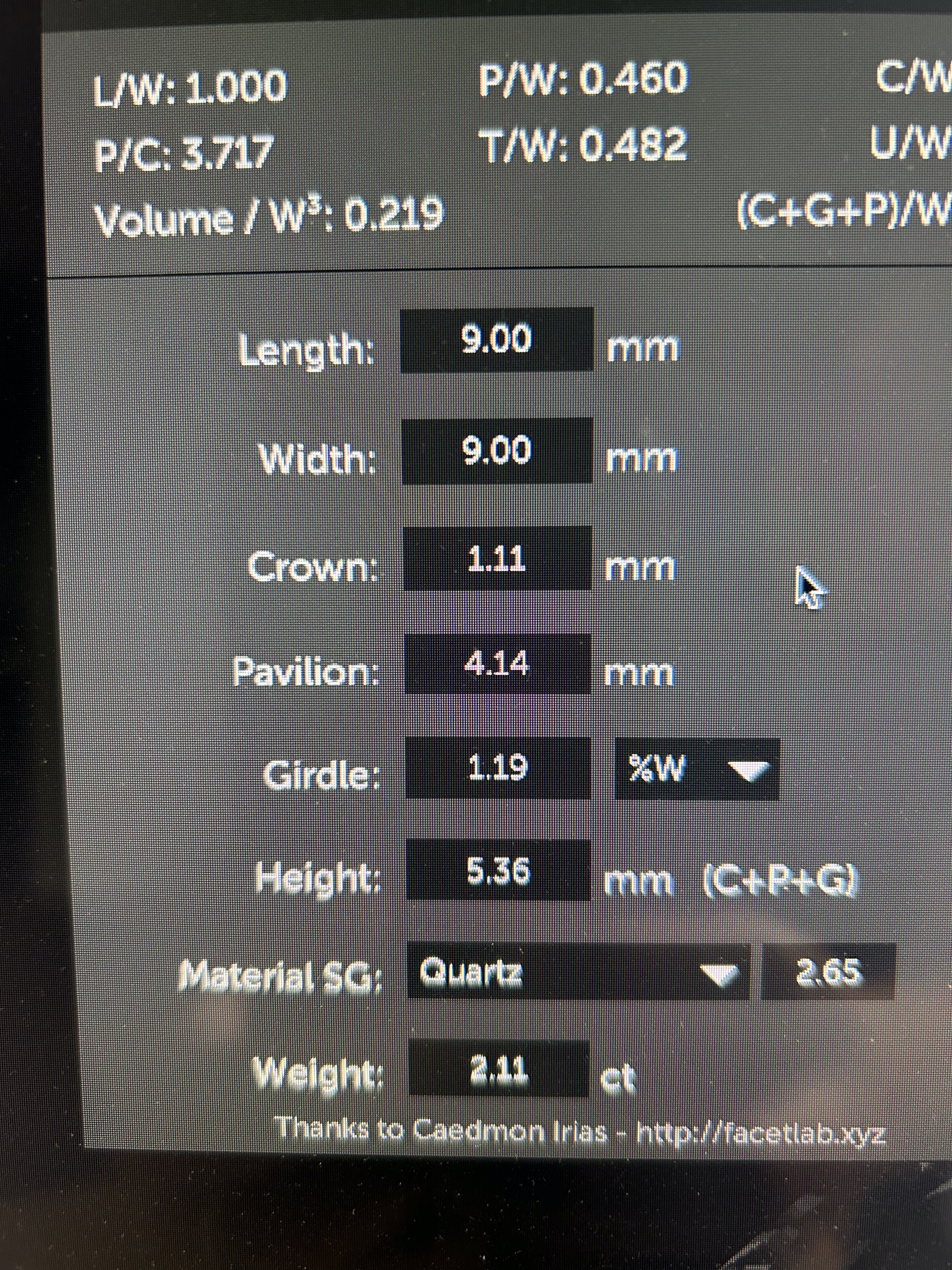

Once the girdle was finished I noticed that I had a much longer cylinder than needed for the width. I checked the design in the CAD software to see what the total height of the stone will be given the 9mm width.

I measured the height and decided that I could get two stones out of this piece, so measured and marked a cut.

I changed to my saw attachment and cut off the top to be saved and used for another day.

Next I set my angle to the next tier of 55 degrees and cut in the next tier.

Once done, the rough in looks like this:

At this point everything I've done is not very accurate and really rough, and I'm fine with that. The whole point of this stage is to remove most of the material in preparation for the higher precision work.

In the next post I'll be fine tuning the first two tiers and cutting in the remaining pavilion tiers.