this post was submitted on 28 Dec 2023

28 points (100.0% liked)

Knitting

2117 readers

57 users here now

A place to show off your knitting, ask questions, and generally enable each other!

CURRENT THEME

🧶 CABLES 🧶

LAST WINNER

RULES

-

All instance rules apply: see legal.lemmy.world

-

WIP/FO Posts should include pattern details (at least name, preferably link)

-

Relevant self-promo from community members is acceptable but will be handled on a case-by-case basis. Exclusively salesy posts will be removed. (more info)

UPCOMING THEMES

TBA!

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

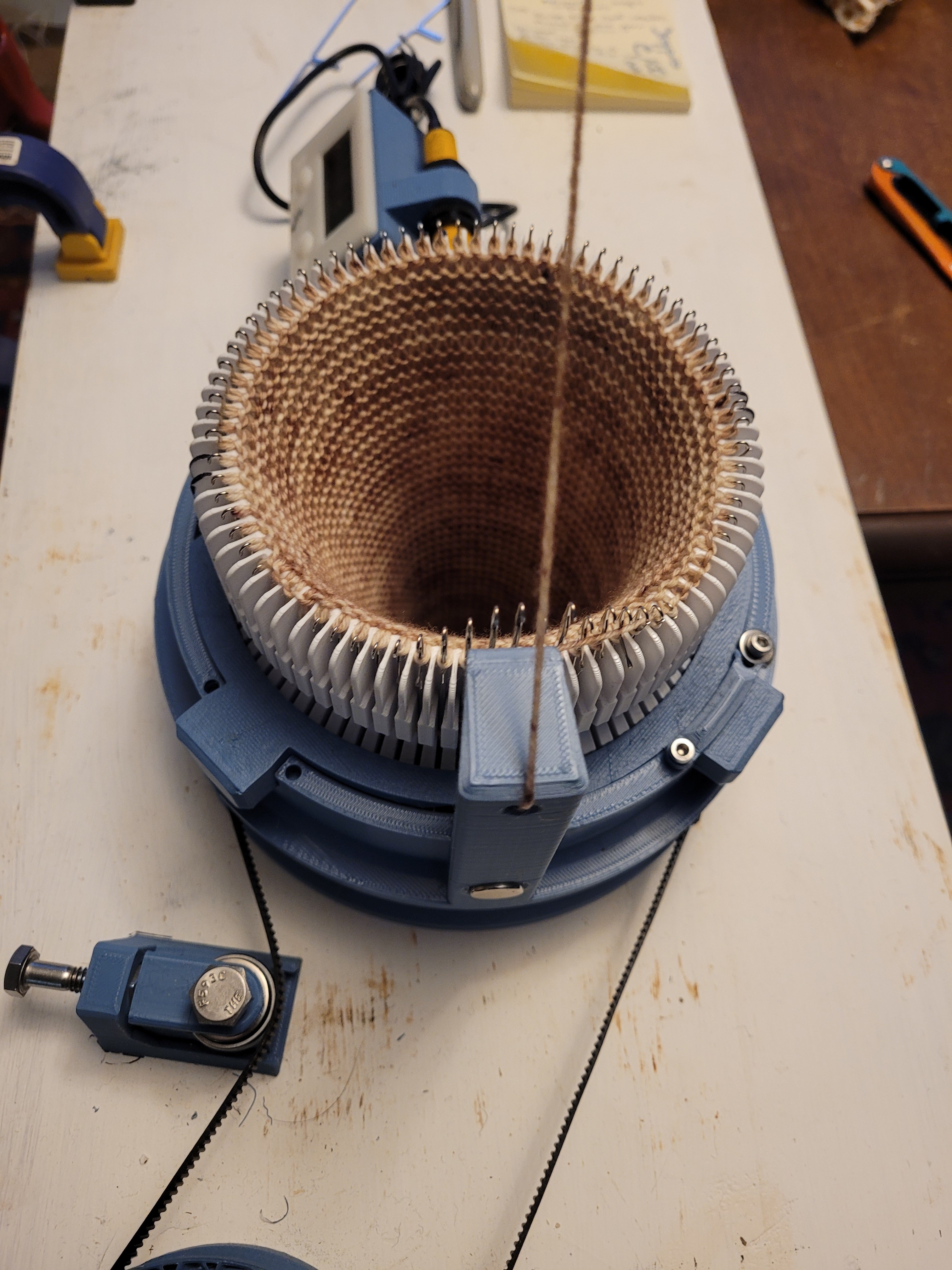

Whoa! That's really neat. Do you have a picture or video of your machine? I've wanted a CSM for years. I could never justify the price. Never occurred to me that you can make your own.

https://m.youtube.com/watch?v=2y1gakl4IEw

I don't have videos of mine but I used the model from the video above and it shows assembly/use. I should note that he specifically says you can't do a heel/toe on the machine because it only turns one way. But, if you use both guides it CAN crank both ways. However, it tends to get jammed on me when doing decreases due to too much friction. So, I just crank a tube and do the afterthought... Still a huge time saving.

Here's a picture of it during some lightweight/fingering turning from a couple of days ago.

All in, I've got maybe $75 into the build if you don't count time. It was fun, so I don't : )

"Dean and Bean" (I think) sells a printed version for something like $400? Of course, the metal ones go for multiple thousand.

Thanks for sharing the video and the photo. That looks like it is going to be great for making lots of socks!

I'll have to look into the dean and bean machine.