this post was submitted on 14 Jun 2023

5 points (100.0% liked)

Laser Cutting

146 readers

1 users here now

A place to share your laser cutter creations, tips, questions and other laser cutter related information.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

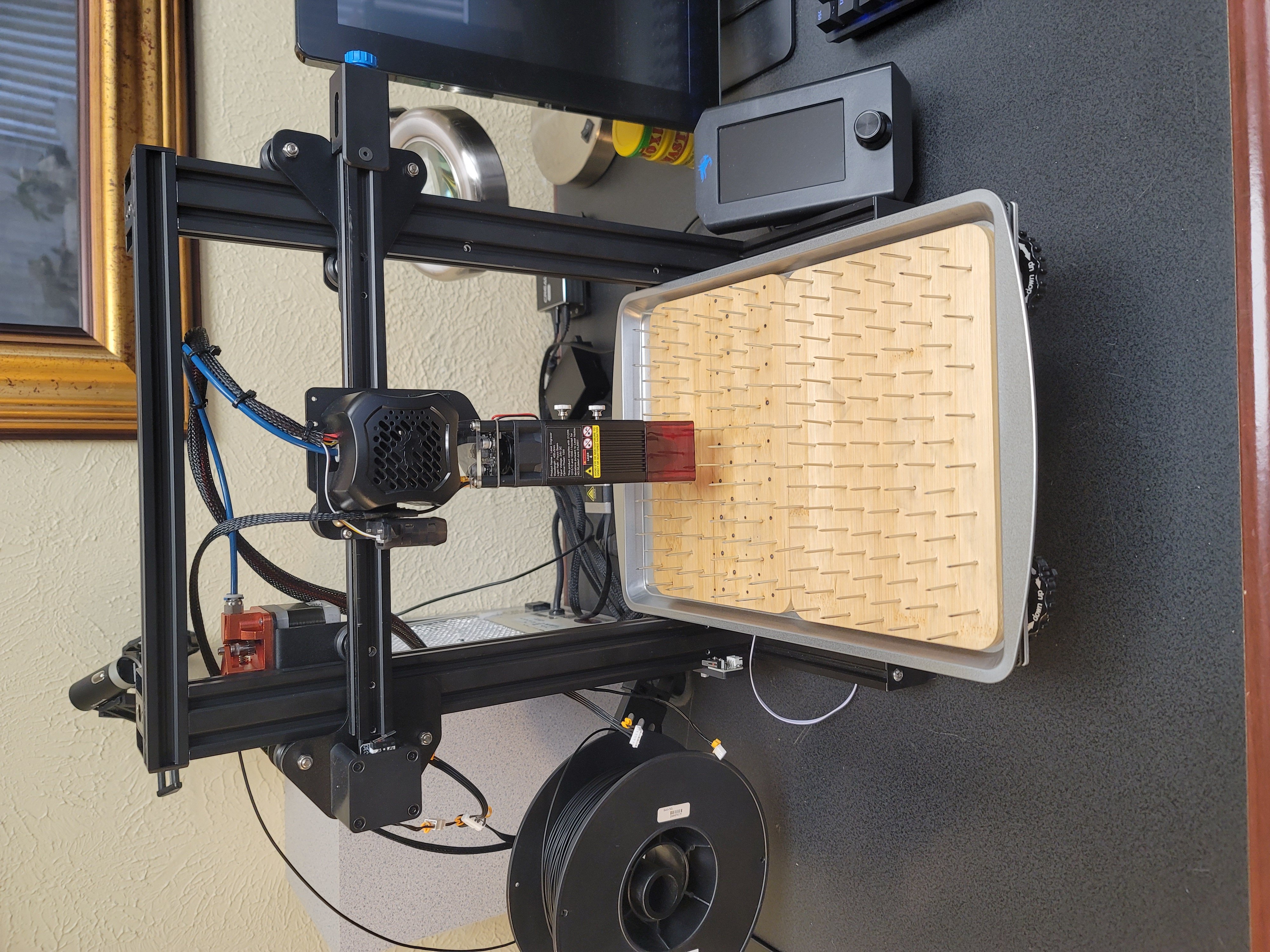

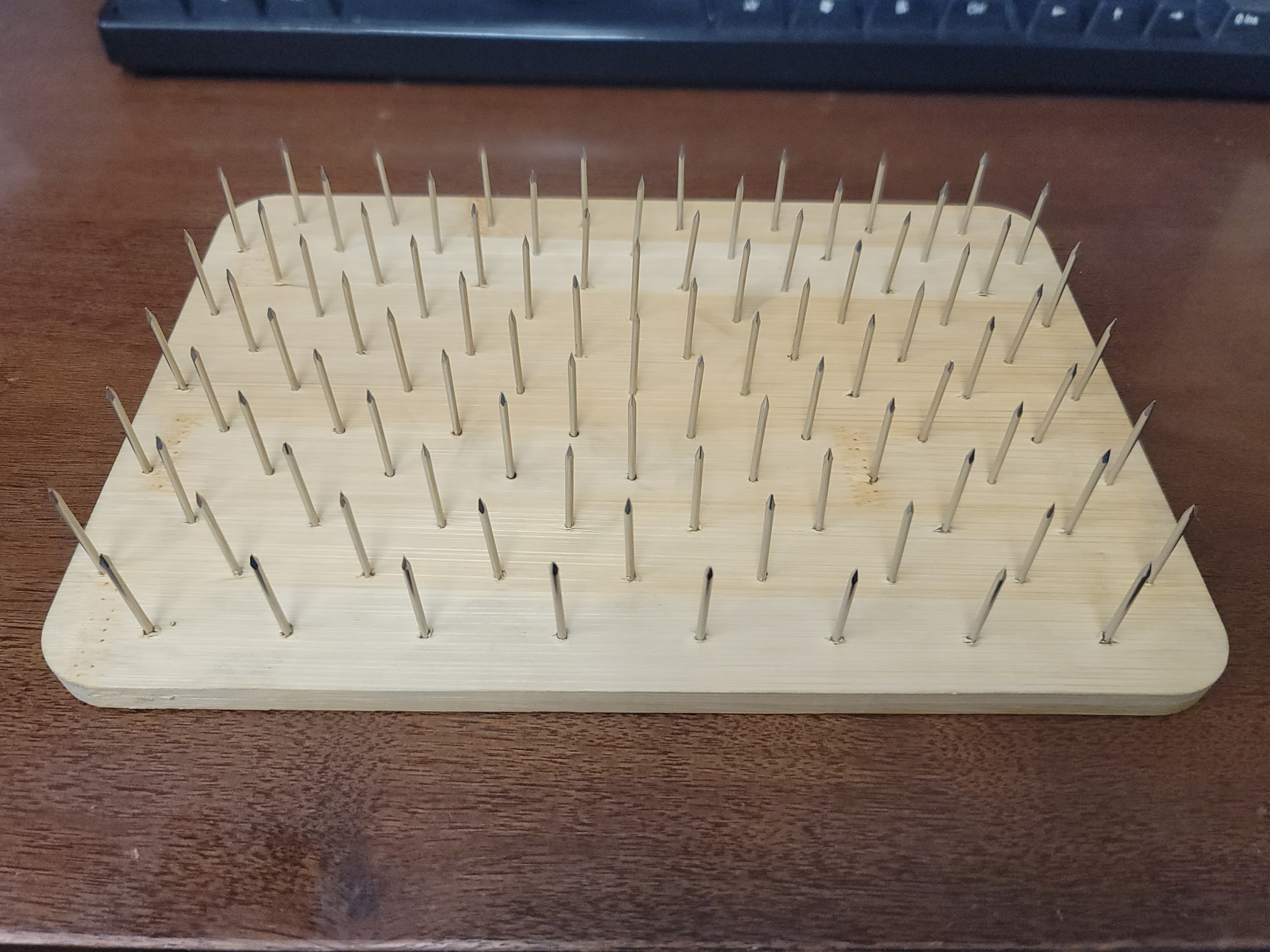

In its stock configuration my fully enclosed cutter is not able to handle the additional height of the board and nails, so I would have to figure out something there first. It should be possible though as they do sell a raiser with a honeycomb panel seperately. So far the included aluminum triangular prisms do the job. But I am keeping your idea in mind.

For the workflow, yes, I open the default Inkscape svg files with XCS, sometimes with a raster image included for engraving. All manufacturing specific settings are done in the machine's software then, so things like path colors and width are ignored. For all the praise it gets I expected to miss LightBurn more and on the side I am learning more and more about Inkscape.