Soldering

This community is for electronic hobbyists to discuss projects and is focused on soldering. Everyone is welcome from the noob to people who have been soldering as a hobby for decades to people who solder professionally. We'll talk about materials and techniques, equipment, and projects. Everyone is welcome. All questions are welcome. Post photos and ask for help.

RULES:

-

All Lemmy.ca rules apply here.

-

Everyone (see rule 98) is welcome.

-

If you’ve seen a question 100 times answer it the 101st time or ignore it. Even better, write a complete, detailed answer and suggest that the mod(s) pin it to the community.

[Did you actually think there were 98 rules?]

-

If you present something as fact and are asked to provide proof or a source provide proof or a source. Proof must be from a reliable source. If you fail to provide proof or a source your post or comment may be removed.

-

Don’t be a dick. Yes, this is a catch-all rule.

-

The mod(s) have the final say.

view the rest of the comments

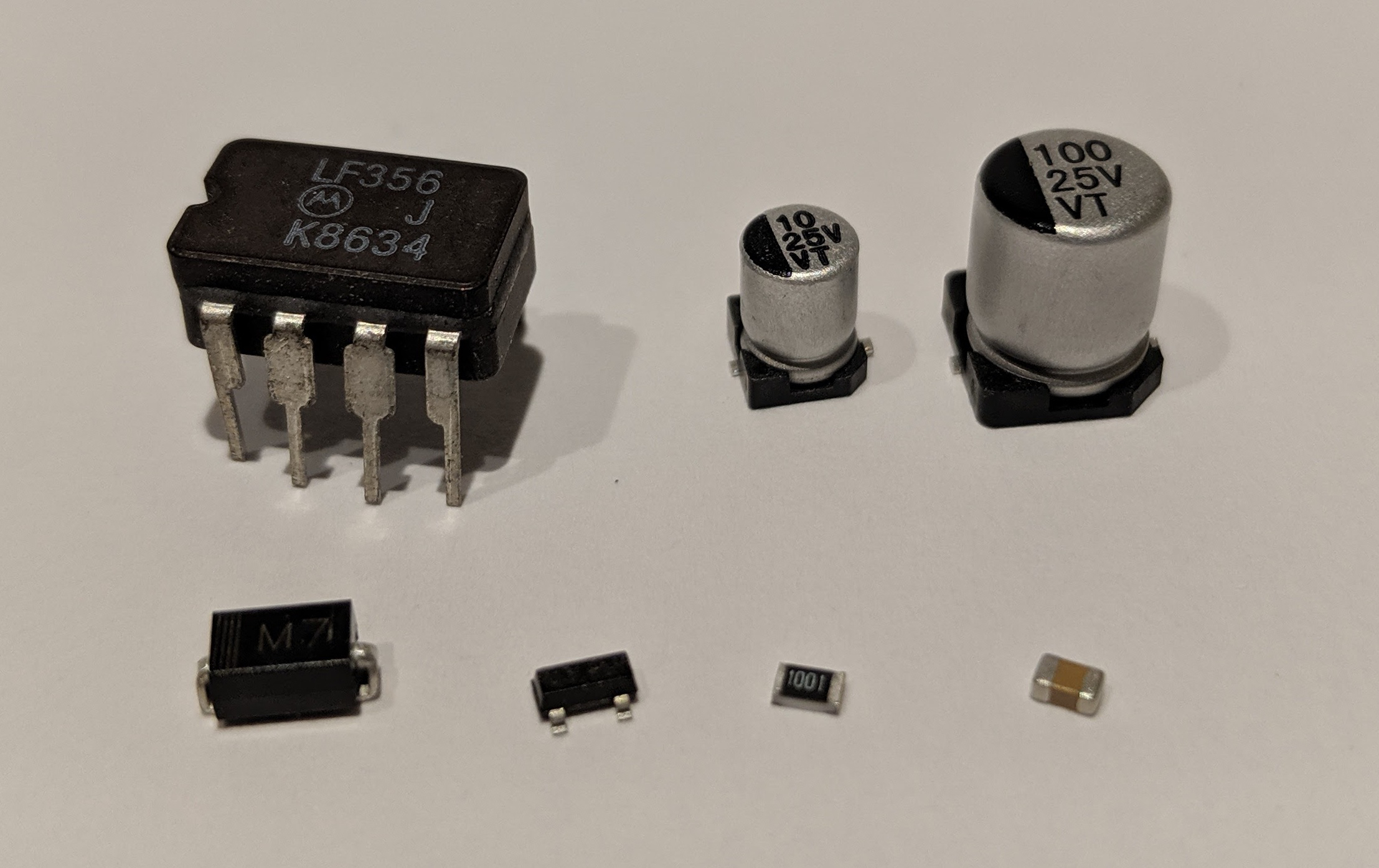

It is harder for a beginner with a $10 soldering iron from the local hardware store than it was when I started 45 years ago. Most people don't start with hot plates or reflow ovens or hot air.

True. I mean you can still find most parts that you used 45 years ago, but making it small and using modern parts might require some new tools. You can get a tiny hot plate on Ali for cheap, but I'm not sure how good it is. There are people utilizing cheap irons as well.

I've seen the tiny ones. I think I'm more likely to build a small reflux oven. I only ever build one or two of anything unless I take in a job for someone else.

Are there good instructions out there for people using cheap irons to solder these small components? How does one get into soldering now with a hot plate vs hand iron considering that these components have a much higher learning curve than the older larger parts ?

I haven't looked into it, but I guess I would start at instructables.com or maybe YouTube

The cheap soldering irons are tricky because heat distribution is crucial. If your iron is not at the right temperature and the heat transfer is not uniform you can fry a component instantly, specially the smaller components. you need a soldering iron with temperature dials at bare minimum

If you want to do really low investment hot plate soldering, some solder paste, good tweezers and a frying pan with some sand in it is probably good. Just keep an eye on it while heating, and stop when the solder melts

I'm working on making some videos to show what can be done with basic equipment even with modern, small components. Maybe I should add some soldering 101 type videos? I can add them to my YouTube channel for my 6 subscribers. Heh.

EDIT: 9! 9 subscribers! Pretty soon I'll be able to quit my day job and live off my YouTube channel.

I'm going to sub too!! But I need a link!

I may not be able to handle the pressure.

https://www.youtube.com/@MapleEngineering

Subbed !

Noice. Thanks.

You're saying that as if most beginners start with smt. Nowadays if you want to build your circuit you can have it made with the PCB already soldered at very affordable prices.

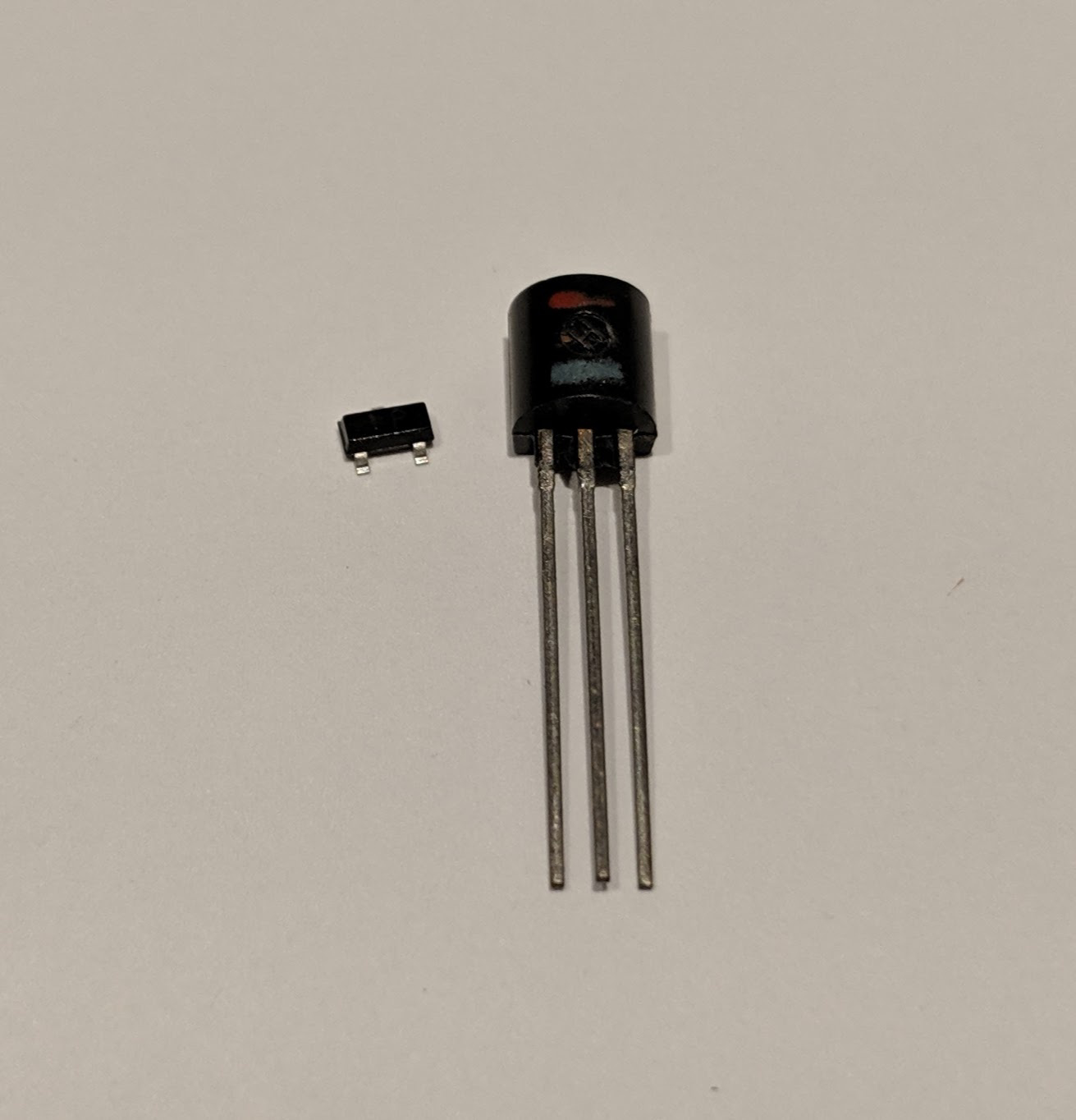

What I'm saying is that it's possible for beginners with basic equipment to begin to work with SMDs. Sure, you can order THT components and build all THT boards but the people that I talk to want to use modern components and modern techniques so that they boards don't look quite so...1970s.

SMDs have made things more challenging but with basic equipment and knowledge it is doable.