this post was submitted on 02 Aug 2024

8 points (100.0% liked)

FreeCAD

925 readers

1 users here now

Your own 3D parametric modeler.

FreeCAD is an open-source parametric 3D modeler made primarily to design real-life objects of any size. Parametric modeling allows you to easily modify your design by going back into your model history and changing its parameters.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

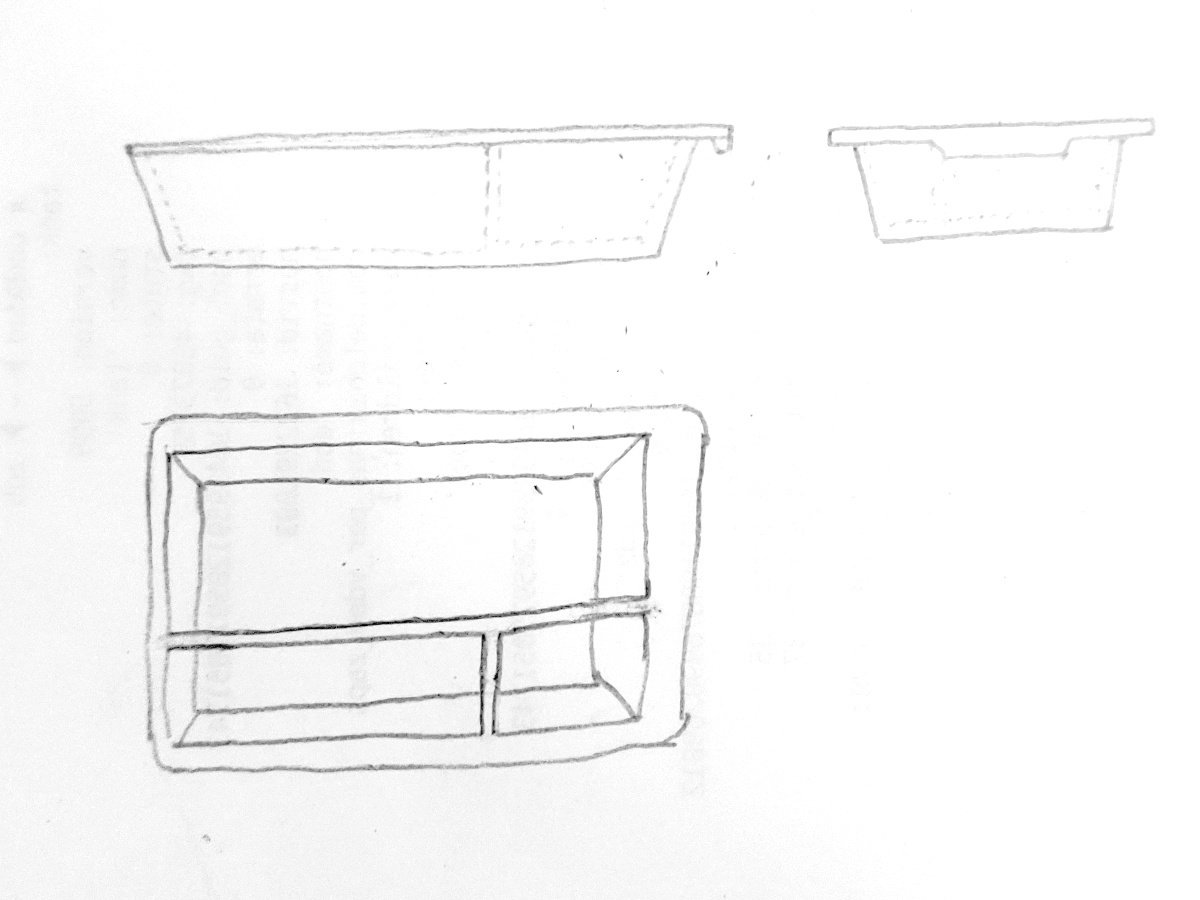

I would make the tapered main bucket out of a loft made of two sketches that describe the dimensions of the upper and lower extremities of the shape. This can be hollow; there is no need to put a hole through it with a pocket. The hole and outer walls can be part of your sketch.

Similarly do not fillet the corners with PartDesign fillets. I mean, you can if you really want to but you can just use Sketch fillets inside your sketches and then FreeCAD won't incessantly break your fillets (and thus the model) any time you change anything...

Example:

If everything needs to be tapered, honestly I would use lofts for all of the vertical components. Make liberal use of the "carbon copy" sketcher feature to make construction lines out of your two master sketches, and then all the other sketches you make for the dividers, perimeter lip, etc. can automatically tie themselves to any dimension adjustments you make to the bin itself.

Example .FCStd file: here.

Edit: It occurs to me that you could also make the tapered tray body by making a solid loft with no hole in it and then using the Thickness tool on the resulting It solid. This would be mechanically simpler, but would result in not having sketch geometry of either the inner or outer wall (depending on which side you tell the thickness to be on) which might hamper future additions/modifications.