this post was submitted on 27 Jul 2024

30 points (100.0% liked)

Woodworking

6241 readers

3 users here now

A handmade home for woodworkers and admirers of woodworkers. Our community icon is submitted by @[email protected] whose father was inspired to start woodworking by Norm and the New Yankee Workshop.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

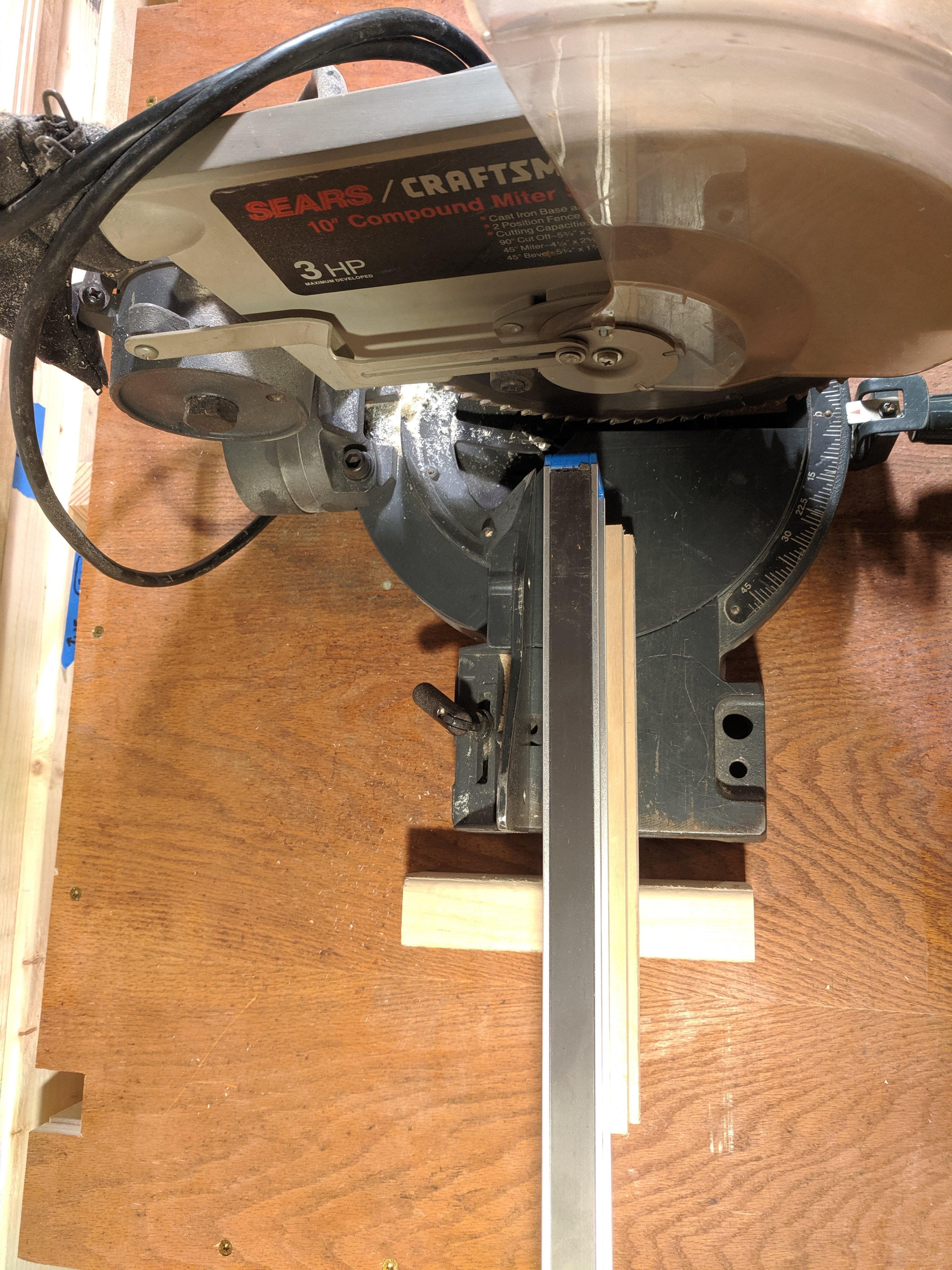

Yes, I would use machine bolts through those holes there. You may want to install some one-by underneath, but you can probably get away with just the plywood if you use a fender washer on the underside. I would also recommend a washer under the head of the bolt.

Yeah, that should be fine. It’s not exactly a massive saw. If OP wants to go “belt and suspenders,” a couple of U-bolts in the mounting holes for the old rod extensions might also be helpful. I think even a single generation later, most miter saws had proper mounting holes, though.

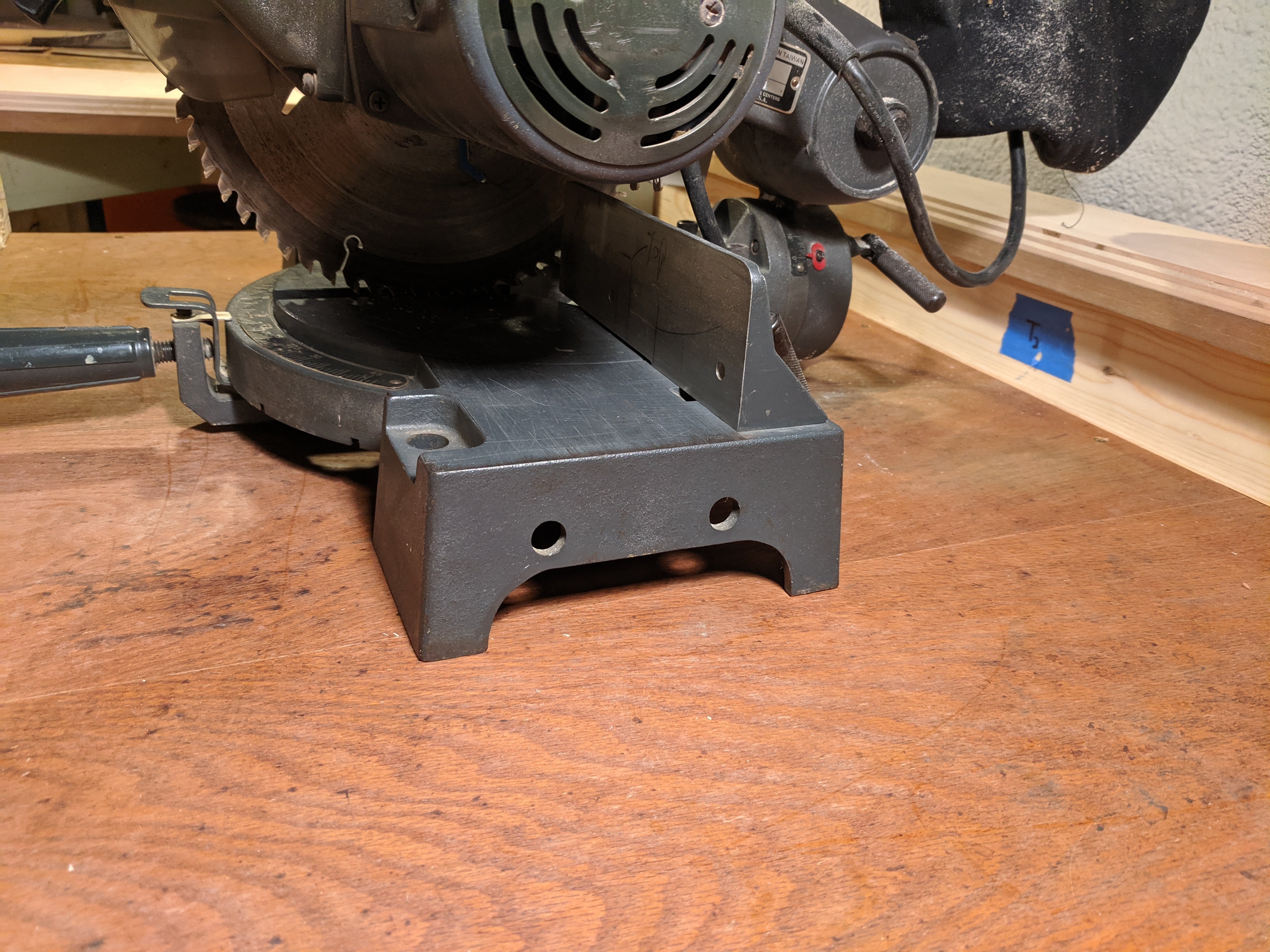

U bolts worked out very well!

Glad to hear it. In revisiting it, the steel will be harder than the casting, which is also a bit thin below those holes, but if it doesn't wiggle a ton, and you don't just drop the whole contraption on the ground, it should last quite a while.

Good caution. It doesn't seem to shift and I tend to flip it pretty slowly, so hopefully it won't put undue stress on the casting.

Yeah, I inherited this one free, but had planned to get a new one when I set out on this project.

I like the idea of u bolts, that seems better than attaching to an extra wood block.