Soldering

This community is for electronic hobbyists to discuss projects and is focused on soldering. Everyone is welcome from the noob to people who have been soldering as a hobby for decades to people who solder professionally. We'll talk about materials and techniques, equipment, and projects. Everyone is welcome. All questions are welcome. Post photos and ask for help.

RULES:

-

All Lemmy.ca rules apply here.

-

Everyone (see rule 98) is welcome.

-

If you’ve seen a question 100 times answer it the 101st time or ignore it. Even better, write a complete, detailed answer and suggest that the mod(s) pin it to the community.

-

Don't tell other users what they should have done of that what you do is better. You do what you want to do and let other people do what they want to do. What is best for you might not be best for others.

[Did you actually think there were 98 rules?]

-

If you present something as fact and are asked to provide proof or a source provide proof or a source. Proof must be from a reliable source. If you fail to provide proof or a source your post or comment may be removed.

-

Don’t be a dick. Yes, this is a catch-all rule.

-

The mod(s) have the final say.

view the rest of the comments

This reminds me of high school. I took an electronics course and we had to hand etch our boards with tape and acid.

Oh man, I remember doing that. We had rub on transfer traces and pads that we could apply to the board before etching that did a good job. I used to buy those at Radio Shack.

My friends, the ones I take in the microscopic soldering jobs for, have a small CNC mill that they can use to mill boards. That's very cool.

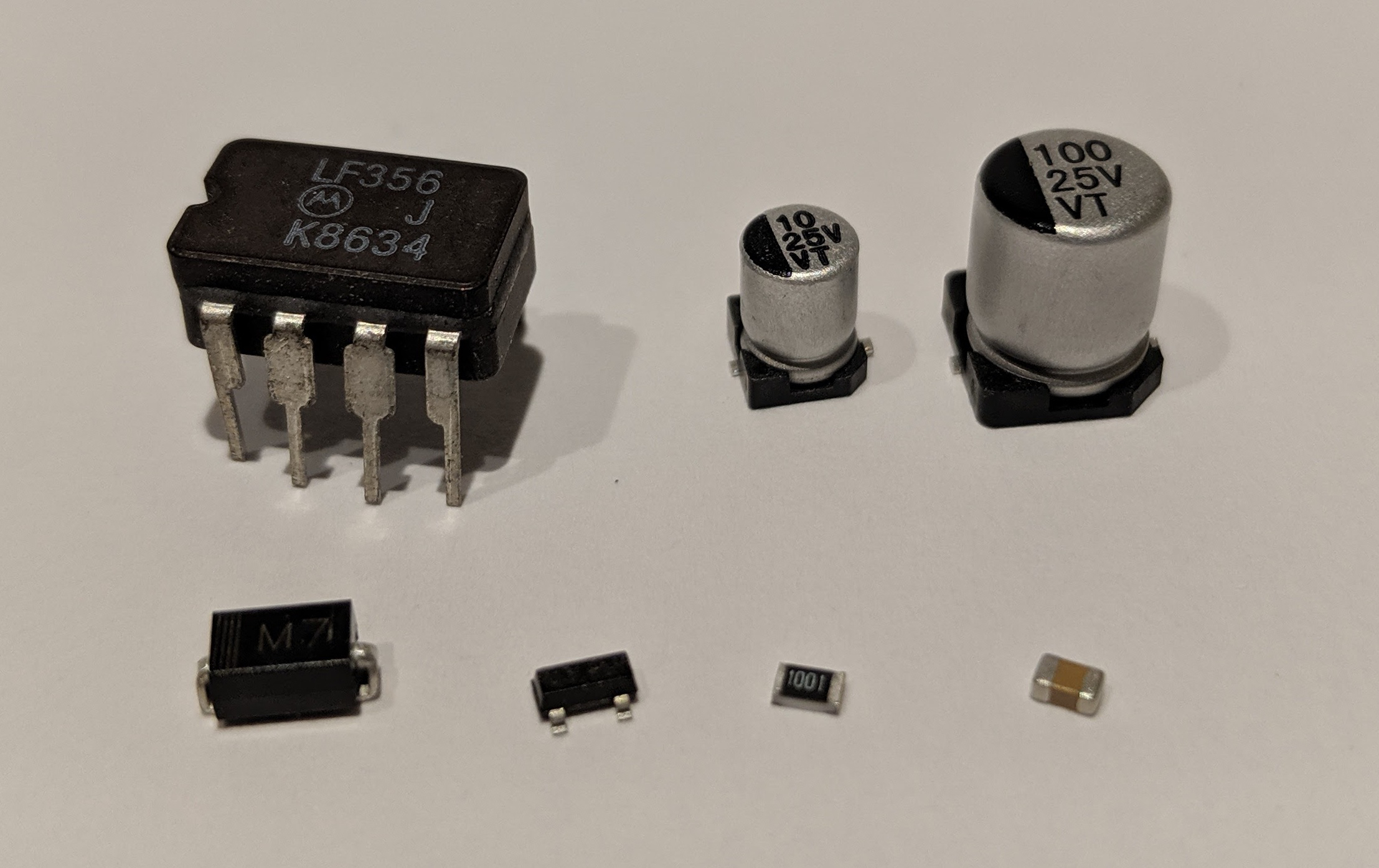

I miss radio shack ! Yeah 2003 baby hah. I wish I could do microscopic soldering

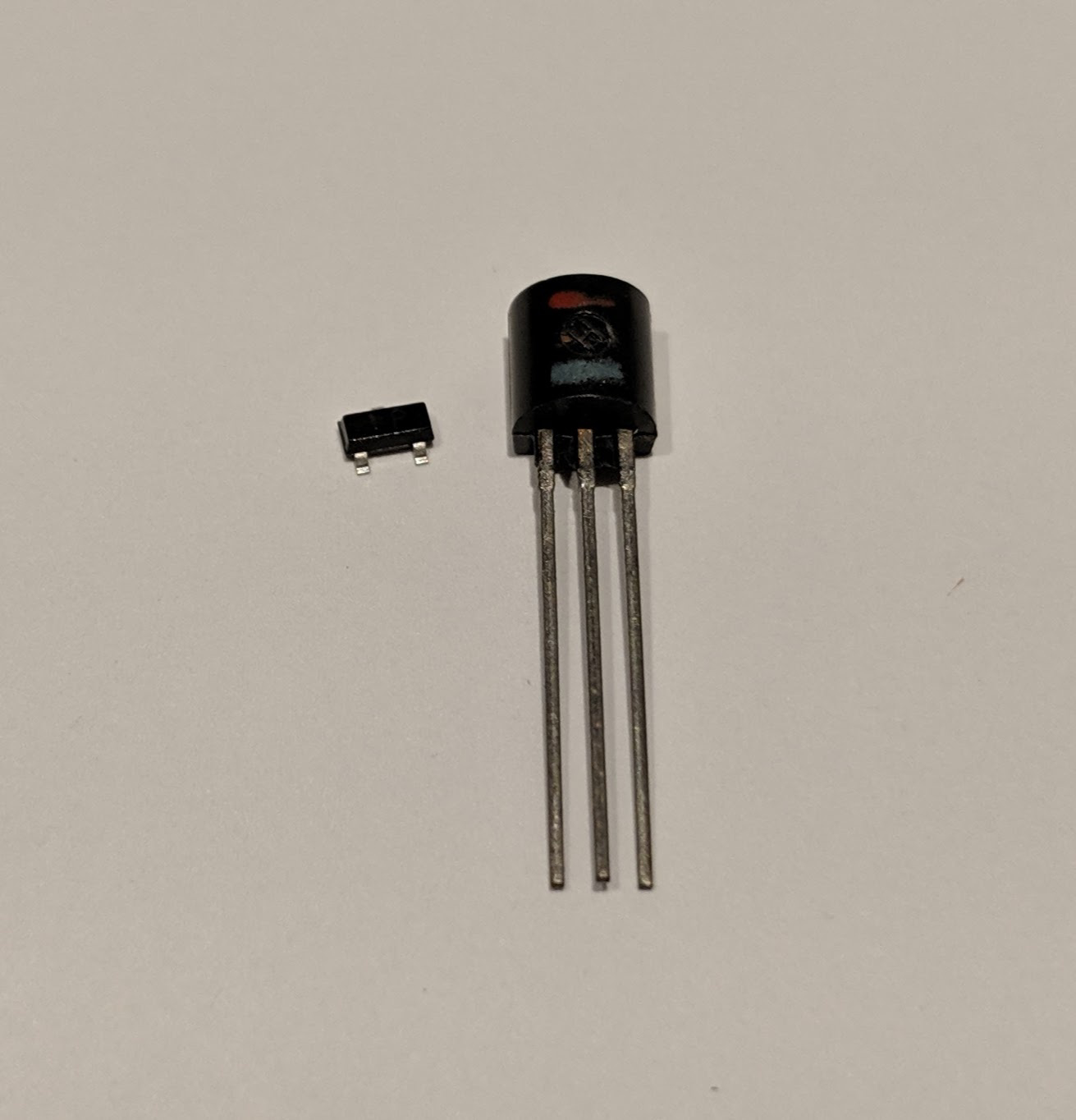

I bought a Olympus SZ40 on an arm for $200 from a microscope shop in Montreal. It's the best $200 I've ever spent. It makes soldering so much easier.